ACI 211.4R-93 Guide for Selecting Proportions for High-Strength Concrete with Portland Cement and Fly Ash

ACI 211.4R-93 Guide for Selecting Proportions for High-Strength Concrete with Portland Cement and Fly AshMixture proportioning procedure

These proportions will then furnish the foundation for field trying out concrete batches from which the optimum

mixture proportions can also be chosen.

For high-strength concretes made except HRWR, a recommended slump vary of 2 to 4 in. may additionally be chosen according to the kind of work to be done. A minimum value of 2 in. of hunch is advocated for concrete without HRWR. Concretes with less than 2 in. of slump are tough to consolidate due to the excessive coarse aggregate and cementitious materials content.

The required concrete electricity to use in the trial mixture process must be determined the use of the guidelines supplied in Chapter 2.

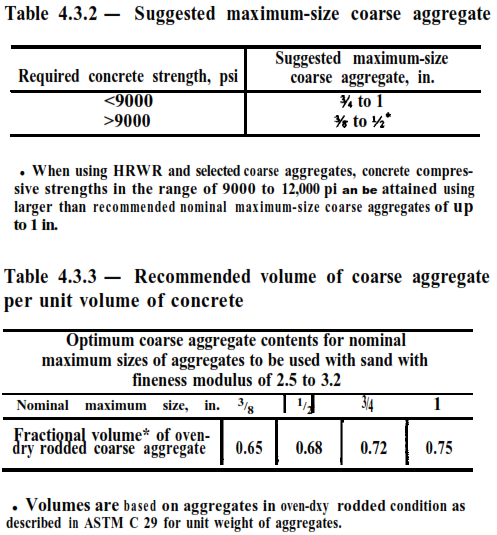

2. Step 2-Select most measurement of aggregate-Based on power requirements, the recommended maximum sixes for coarse aggregates are given in Table 4.3.2. ACI

318 states the most size of an aggregate have to not exceed one-fifth of the narrowest dimension between sides of forms, one-third of the depth of slabs, nor three-quarters of the minimum clear spacing between individual reinforcing bars, bundles of bars, or prestressing tendons or ducts.

3. Step 3-Select most reliable coarse aggregate content -The most advantageous content material of the coarse combination depends

on its strength potential traits and maximum size. The advocated superior coarse aggregate contents, expressed as a fraction of the dry-rodded unit weight

(DRUW), are given in Table 4.3.3 as a function of nominal maximum size.

Once the most efficient coarse mixture content has been chosen from Table 4.3.3, the oven-dry (OD) weight of the coarse combination per yd3 of concrete can be calculated

using Eq. (4-1)