The aircraft fuel system is a complex network of components and mechanisms designed to store, manage, and deliver fuel to the engines.

What is Aircraft Fuel System?

The aircraft fuel system serves as a critical component in ensuring the safe and reliable operation of the aircraft’s power plant. Its primary purpose is to provide a consistent and uninterrupted supply of fuel to the engines. Without a properly functioning fuel system, the aircraft cannot operate, except in the case of gliding.

Two common types of fuel used in aircraft are high-octane gasoline for piston-powered aircraft and various types of kerosene for jet aircraft. Regardless of the fuel type and mission requirements, aircraft fuel systems must fulfill several fundamental needs:

- Refuel and Defuel: The system must facilitate the safe and efficient refueling and defueling of the aircraft. This process involves connecting fuel hoses or hydrants to the aircraft’s fuel tanks while adhering to strict safety protocols.

- Storage: Fuel tanks provide storage for the aircraft’s fuel supply. These tanks are strategically located within the aircraft’s structure, often in the wings, fuselage, or tail section, depending on the aircraft’s design.

- Fuel Pressurization: In some aircraft, fuel pressurization systems are employed to ensure a steady flow of fuel to the engines, especially during high-altitude flight where atmospheric pressure is lower.

- Fuel Transfer: Larger aircraft with multiple fuel tanks may require systems for transferring fuel between tanks to maintain proper weight distribution and balance.

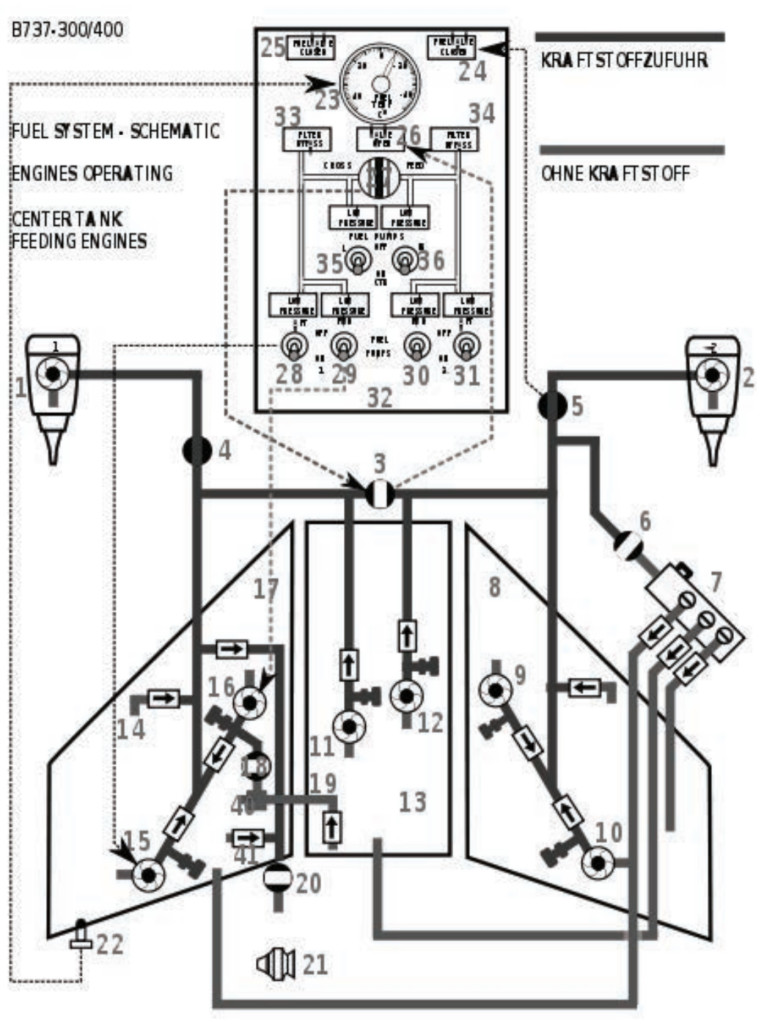

- Engine Feed: Fuel pumps and fuel lines deliver fuel from the tanks to the engines, ensuring a consistent supply of fuel to support engine operation.

- Pipes and Conducts: The fuel system consists of a network of pipes, conduits, and hoses that transport fuel throughout the aircraft, from the tanks to the engines and other components.

- Valves and Filters: Valves and filters are essential components of the fuel system, regulating the flow of fuel and removing contaminants or impurities to ensure clean fuel reaches the engines.

- Sensors, Indicators, and Control Elements: Sensors and indicators provide pilots with real-time information on fuel quantity, pressure, and other critical parameters. Control elements allow pilots to manage and adjust fuel flow as needed during flight.

The aircraft fuel system is composed of various components, including tanks, fuel hydrants, pumps, pipes, valves, filters, sensors, indicators, and control elements. Together, these elements work in concert to ensure the safe and efficient delivery of fuel to the aircraft’s engines, thereby enabling safe flight operations.

Aircraft Fuel Tanks

Aircraft fuel tanks play a crucial role in storing fuel for the aircraft’s operation, and there are three main types distinguished by their design and functionality: independent tanks, integrated tanks, and interchangeable tanks.

- Independent Tanks: These tanks, similar to those found in automobiles, are now largely obsolete and mainly used in regional aircraft. They operate independently from the aircraft’s structure and are standalone units.

- Integrated Tanks: Integrated tanks are the most common in commercial aviation. They are structurally integrated into the aircraft, typically within the wings. These tanks are coated internally with anti-corrosion substances and sealed to prevent leaks, forming an integral part of the aircraft’s structure.

- Interchangeable Tanks: Interchangeable tanks are installed for specific missions or purposes and can be swapped out as needed. These tanks are designed for flexibility and adaptability to varying operational requirements.

The process of filling and emptying fuel from the tanks is centralized at a single point known as the fuel hydrant. Fuel hydrants supply fuel to all tanks via feeding pumps that distribute fuel through the network of pipes and conduits forming the fuel distribution system. There are two fundamental types of pumps:

- Fuel Transfer Pumps: These pumps transfer fuel between the aircraft’s tanks, ensuring proper fuel distribution and balance.

- Fuel Booster Pumps: Also known as engine feed pumps, these pumps boost the fuel flow from the fuel system to the engines, preventing issues like flameouts and ensuring consistent engine performance.

The fuel system is complemented by various components such as valves, filters, sensors, indicators, and control elements:

- Valves: Transfer valves regulate the flow of fuel between tanks, while non-return valves maintain the direction of fuel flow and vent valves eliminate air during refueling.

- Filters: Filters remove contaminants from the fuel system, ensuring clean fuel reaches the engines.

- Sensors: Sensors measure various performance parameters such as fuel quantity, properties, and level.

- Indicators and Control Elements: Indicators display fuel-related data to the pilot, while control units analyze and may automatically adjust system parameters. Pilots and control units can actuate the system to modify its performance as needed.

Overall, the fuel system is an integral part of the aircraft’s operation, ensuring the reliable storage, transfer, and delivery of fuel to the engines while maintaining safety and efficiency. The subsystems encompassing indicators, displays, and control units are also considered part of the broader electronic or avionics system.