The aircraft hydraulic system is a important system that uses fluid power to operate various systems and control surfaces, providing essential functions for flight control, landing gear operation, braking, and other aircraft systems. Aircraft hydraulic system is also called plane hydraulic system.

Aircraft Hydraulic System

Aircraft hydraulic systems have been a cornerstone of aviation technology since the early 1930s and continue to play a vital role in modern airliners. These systems serve the fundamental purpose of supplying power to various hydraulic consumers, including primary and secondary flight controls, landing gear systems, and other essential components like doors. Here are the main advantages of hydraulic systems and their key components:

Advantages of Hydraulic Systems:

- Relative Low Weight: Hydraulic systems offer a favorable power-to-weight ratio, making them efficient in generating the required force for aircraft control and operation while keeping weight to a minimum.

- Simplicity in Installation: Hydraulic systems are relatively straightforward to install compared to alternative power transmission systems, simplifying aircraft design and assembly processes.

- Low Maintenance: Hydraulic systems typically require less maintenance compared to other power transmission systems, contributing to lower operational costs and increased aircraft availability.

- High Efficiency: Hydraulic systems boast high efficiency with minimal energy losses, primarily due to the low friction characteristics of hydraulic fluids. This efficiency ensures optimal performance and reliability in aircraft operations.

Components of a Hydraulic System:

- Energy Source: The hydraulic system can draw power from various sources, including engine-driven alternators, Auxiliary Power Units (APUs), or Ram Air Turbines (RATs), ensuring redundancy and reliability.

- Reservoir or Tanks: These store the hydraulic fluid required for system operation, providing a constant supply to meet operational demands.

- Filter: Filters are employed to maintain the cleanliness of the hydraulic fluid, ensuring the smooth operation and longevity of system components by removing contaminants.

- Accumulator: Accumulators store hydraulic energy, acting as a high-density fluid tank and providing backup power in the event of pump failure or other emergencies.

- Pipeline Manifold: This structure branches into several openings, facilitating the distribution of hydraulic fluid to various components throughout the aircraft.

- Pumps, Pipes, and Valves: Hydraulic pumps, whether engine-driven or electric, along with pipes and valves, control the flow of hydraulic fluid and regulate pressure within the system.

- Mechanism for Hydraulic Oil Cooling: Cooling mechanisms are incorporated to maintain the optimal operating temperature of hydraulic fluid, ensuring system efficiency and preventing overheating.

- Pressure and Temperature Sensors: Sensors monitor pressure and temperature within the hydraulic system, providing crucial data for system operation and maintenance.

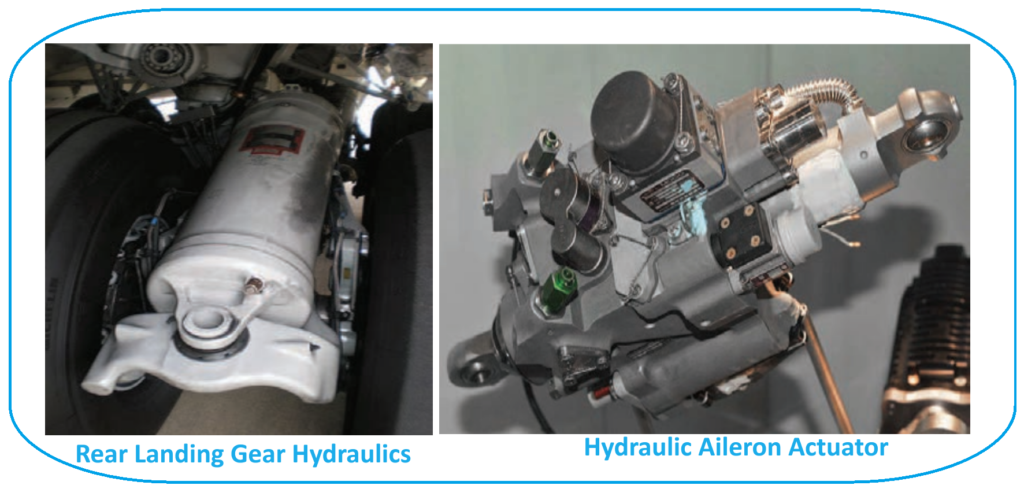

- Actuators: Actuators mechanically actuate on devices such as flight control surfaces, landing gear systems, and doors, translating hydraulic pressure into mechanical force to perform specific functions.

In essence, the aircraft hydraulic system’s robust design and efficient operation make it indispensable for ensuring safe and reliable aircraft control and operation, contributing significantly to the advancement and success of modern aviation.

Functions of an Aircraft Hydraulic System:

- Hydraulic Fluid: The system relies on hydraulic fluid, typically a special type of oil with specific properties suitable for the high-pressure and temperature conditions encountered in aircraft operations. This fluid serves as the medium for transmitting power within the system.

- Hydraulic Pumps: Hydraulic pumps are responsible for generating hydraulic pressure by pressurizing the hydraulic fluid. There are different types of pumps used in aircraft hydraulic systems, including engine-driven pumps, electrically-driven pumps, and hand pumps for backup or emergency operation.

- Reservoir: The hydraulic system includes a reservoir or hydraulic fluid tank that stores the hydraulic fluid. This reservoir ensures a constant supply of fluid to the system and allows for expansion and contraction of the fluid due to temperature changes.

- Actuators: Actuators are devices that convert hydraulic pressure into mechanical force to perform specific tasks. In aircraft, hydraulic actuators are used to move control surfaces such as ailerons, elevators, and rudders, as well as operate landing gear, flaps, and other systems.

- Valves and Manifolds: Valves control the flow of hydraulic fluid within the system, directing it to different actuators or systems as needed. Manifolds are distribution points that route hydraulic fluid to various components of the system.

- Filters: Filters are employed within the hydraulic system to remove contaminants and maintain the cleanliness of the hydraulic fluid. Clean hydraulic fluid is essential for the proper operation and longevity of the system components.

- Pressure Relief Valves: Pressure relief valves are safety devices designed to prevent the hydraulic system from exceeding its maximum pressure limit. These valves ensure the system operates within safe parameters and protect against damage or failure due to overpressure.

- Accumulators: Accumulators store hydraulic energy in the form of compressed gas or fluid, providing a backup power source in case of pump failure or other emergencies. They can also help dampen hydraulic pressure fluctuations and maintain system pressure during transient conditions.

- Control Systems: The hydraulic system is often integrated with the aircraft’s control systems, including flight control computers and hydraulic control valves, to ensure precise and responsive control of aircraft surfaces and systems.

- Maintenance and Monitoring: Regular maintenance and monitoring of the hydraulic system are essential to ensure its reliability and safety. This includes inspections, fluid checks, filter replacements, and testing of system components to detect and address any issues before they escalate.