This article is about requirements for manufacturing, testing of 115 and 230 kV Cross-Linked Polyethylene (XLPE) power cables and accessories. Main keywords for this article are Cables 115 and 230 kV Test, Requirements for 115 kV Cables, Cables 115 and 230 kV Design Requirement IEC or NEC, Cables 115 and 230 kV References.

Cables 115 and 230 kV References

Association of Edison Illuminating Companies (AEIC)

CS9 Specification for Extruded Insulation Power Cables And Their Accessories Rated Above 46kV Through 345 kV

Insulated Cable Engineers Association (ICEA)

P-45-482 Short Circuit Performance of Metallic Shields and Sheaths of Insulated Cable

International Council on Large Electrical Systems (CIGRE)

WG 21.03 CIGRE Working Group 21-03; Recommendations for Electrical Tests Type, Sample and Routine on Extruded Cables and Accessories at Voltages >150 (170) kV and < 400 (420) kV

International Electrotechnical Commission (IEC)

60228 Conductors of Insulated Cables

60287-1-1 Electric cables – Calculation of the current rating –Part 1-1:Current rating equations (100 % load factor) and calculation of losses –General

60332 Tests on Electric Cables under Fire Conditions

60502 Extruded Solid Dielectric Insulated Power Cables Rated Voltages 1 kV to 30 Kv

60811 Common Test Methods for Insulating and Sheathing Materials of Electric Cables

60840 Tests for Power Cables with Extruded Insulation for Rated Voltages 30 kV up to 150 kV

Cables 115 and 230 kV Design Requirement IEC or NEC

- 115 kV rated power cable shall be manufactured in accordance with AEIC CS9 and tested in accordance with AEIC CS9 or IEC 60840.

- 230 kV rated power cable shall be manufactured in accordance with AEIC CS9 and tested in accordance with CIGRE WG 21.03.

Cable Installation

- All cables shall be suitable for use in wet and dry locations, indoors and outdoors, in cable tray, trenches, in underground ducts and for direct burial.

- The cable vendor shall either perform all site installation work or supervise the installation by others, and shall have proven installation record of 5 years.

Cable Ampacity

- Standard cables sizes are shown in section 9 for 115 kV cables, and in section 10 for 230 kV cables.

- The cable vendor shall calculate the ampacity for all cables based on actual site and installation conditions, in accordance with IEC 60287-1-1.

- Cable sizing shall be based on a maximum continuous temperature of 90 °C, and emergency loading to 105 °C.

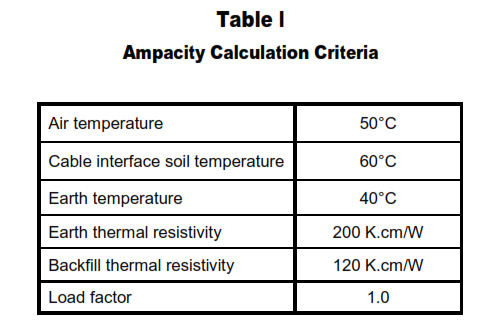

- Criteria in Table I shall be used for ampacity calculation:

Cable Construction

- Standard conductor sizes and minimum requirements for cable components shall be as shown in section 9 for 115 kV cables, and in section 10 for 230 kV cables.

- The conductors shall be plain annealed stranded copper conductors conforming to IEC 60228 Class 2.

- Conductors above 1000 mm2 shall be segmental.

Conductor Shield

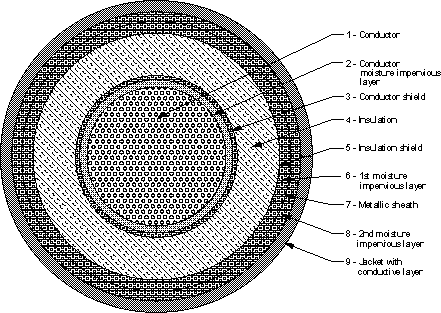

- A conductor moisture – impervious layer (longitudinal water barrier) shall be applied between the conductor and the specified, extruded, semi-conducting layer.

- Conductor shielding shall be required for all cables. The conductor shield shall be an extruded semiconducting layer, compatible with the insulation, and shall have an allowable operating temperature equal to that of the insulation. A nonmetallic semiconducting tape shield shall not be acceptable. The conductor shield shall be easily removable from the conductor without leaving any residue. The thickness of the conductor shield shall be minimum 0.8 mm, with 1.0 mm average thickness.

- The total thermal resistivity of the conductor shield, insulation and insulation shield shall not exceed 0.52 K.m/W.

Insulation

The insulation shall be unfilled, cross-linked, thermosetting polyethylene.

Insulation Shield

- The insulation shield shall consist of an extruded semiconducting layer applied directly over the insulation. The insulation shield shall be easily stripped, leaving no residue on the insulation surface. The insulation shield shall bond to the insulation.

- The extruded semiconducting conductor shield, the insulation, and the semiconducting insulation shield shall be applied by simultaneous triple extrusion. Steam curing shall not be acceptable for XLPE insulated cable. The compound feeding system shall be a closed system, with suitable protection from in-plant contamination.

Metallic Sheath

- A moisture impervious metallic sheath shall encompass the cable core. The metallic sheath shall be designed to allow expansion of the inner cable components at elevated temperatures.

- For cables to be installed below the water table, the metallic sheath shall be an extruded lead alloy sheath. Copper sheath may be added when specified in purchase order, to reduce lead sheath thickness. This will increase flexibility and decrease cable weight. For cables to be installed above the water table, either an extruded lead alloy sheath or a seamless tube of corrugated aluminum shall be used.

- The metallic sheath shall be capable of carrying the fault currents given in sections 10 and 11 without any deleterious effects on the cable. With a starting cable temperature of 90 °C, the highest metallic sheath temperature attained at any part of the cable shall not exceed 200 °C.

- ICEA P-45-482 shall be used by the manufacturer to determine the effective cross-sectional area of the metallic sheath, and its short circuit carrying capability.

Moisture Impervious Layers

- Moisture impervious layers shall be provided as follows:

a. First Layer (longitudinal water barrier) – a layer of semi-conductive water blocking tape or powder, between the insulation shield and the metallic sheath. The thickness of this first moisture impervious layer shall be independent of that of the extruded insulation shield.

b. Second Layer (longitudinal water barrier) – a layer of semi-conductive water blocking tape or powder, between the metallic sheath and the jacket - The minimum thickness of each of the two moisture barrier layers shall be 0.5 mm. The tape shall be helically applied with a minimum 15 percent overlap.

Cable Jacket

- The cable jacket shall be linear medium or linear low density polyethylene (LMDPE or LLDPE) tested in accordance with IEC 60502. The minimum average thickness of the jacket shall be 3.95 mm. The minimum thickness of the jacket shall be 3.55 mm. The jacket shall be resistant to abrasion, oil, flame and weather, including direct sun light. The jacket shall be insect and rodent repellant. The jacket shall be fire resistant and shall meet the requirements of IEC 60332.

- The jacket shall have a semi-conducting coating to permit jacket tests throughout the cable service life. The jacket shall be capable of withstanding a dc voltage test of 10 kV for 5 minutes immediately after installation, and an annual dc test of 5 kV for 5 minutes.

Splicing and Termination

- Vendor shall furnish prefabricated cable splicing kits, as required to provide a complete installation. Cable splicing kits shall be complete in every respect, and shall include the overall housing. The splice shall be designed to be resistant to mechanical damage, corrosion and ingress of moisture.

- The materials of cable splices and terminations shall be fire safe, that is, they shall be self-extinguishing and non-propagating.

- The electrical shielding at splices shall be designed to control electrical stresses due to all normal and abnormal conditions. Proper stress distribution shall preclude ionization and corona discharge within the splice.

- The splices shall be environmentally sealed, and capable of preventing the ingress of external moisture and contamination under severe external contamination and environmental pollution.

- Terminations shall comply with IEC 60840. Splices shall match the electrical, thermal and mechanical properties of the cable. The dielectric geometry of the terminations and the cable shall be compatible. Vendor shall ensure that cable termination kits are compatible with the cable and the GIS switchgear.

Requirements for 115 kV Cables

115 kV cables shall meet the requirements of Table II.

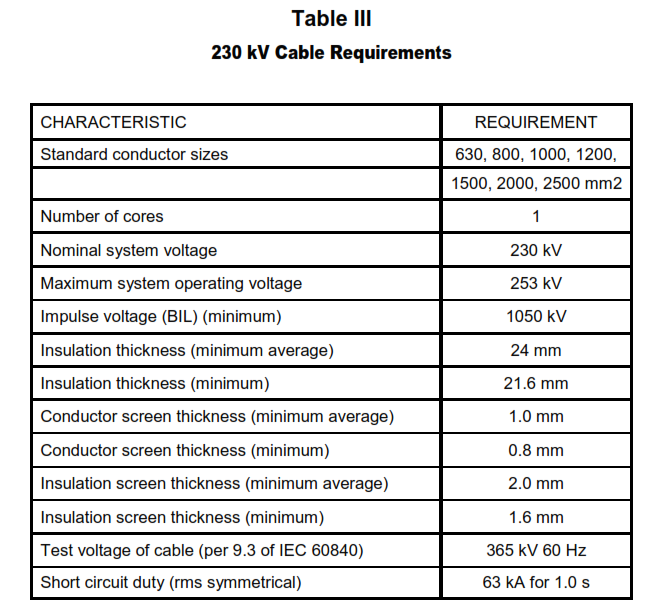

Requirements for 230 kV Cables

230 kV cables shall meet the requirements of Table III.

Main keywords for this article are Cables 115 and 230 kV Test, Requirements for 115 kV Cables, Cables 115 and 230 kV Design Requirement IEC or NEC, Cables 115 and 230 kV References.

Cables 115 and 230 kV Test and Inspection

Routine and Type Tests

- For 115 kV power cable, routine and type tests in accordance with AEIC CS9 or IEC 60840 shall be acceptable. For 230 kV cable, routine and type tests shall be as detailed in WG 21.03.

- The following tests shall be performed:

a. Hi voltage ac test

b. Insulation resistance test

c. Partial discharge test

d. Hi-pot test - A longitudinal water tightness type test shall be conducted on the cable, in accordance with IEC 60840 or WG 21.03.

- The completed reeled cable partial discharge test data shall be submitted on a printed sheet of an X-Y recorder, showing the partial discharge curve of each cable.

- Conductor examination and measurement of resistance in accordance with IEC 60228.

- Measurement of thickness of insulation and sheath thickness in accordance with IEC 60811

- Measurement of thickness of metallic sheath

FIGURE 1

Cross-Section of XLPE Insulated, 115 or 230 kV Power Cable (Typ.)

Main keywords for this article are Cables 115 and 230 kV Test, Requirements for 115 kV Cables, Cables 115 and 230 kV Design Requirement IEC or NEC, Cables 115 and 230 kV References.