This article is about Explosion proof Conduit Fittings and Accessories Material Selection Guide & Specification for commercial buildings, plants and refinery projects as per international codes and standards. EXP fittings and accessories shall be listed as meeting the requirements of UL 886.

Conduit Fittings and Accessories Material Technical Requirements & Specification

| Conduit and threaded conduit fittings shall have tapered (NPT) threads in accordance with ANSI/ASME B1.20.1. |

| Material: A box or a fitting shall be made of ferrous materials, copper, brass, bronze, or aluminum or its alloys containing not less than 80 percent aluminum. A metal such as zinc or magnesium, or their alloys, is not acceptable. [UL 886 Sec. 4.1] |

| Material: Copper shall not be used for a box for use in Class I, Group A locations. A copper alloy shall not be used for a box unless it is coated with tin, nickel, or an equivalent coating, or unless the copper content of the alloy is limited to not more than 30 percent. [UL 886 Sec. 4.2] |

Material: Among the factors that are to be taken into consideration when determining the acceptability of nonmetallic material are:

a) Mechanical strength

b) Resistance to impact

c) Moisture-absorptive properties

d) Resistance to fungus

e) Combustibility

f) Resistance to repeated explosions

g) Resistance to solvents as covered by the hazardous location group

or groups under consideration

h) Resistance to accumulation of electrostatic charges, and

i) Resistance to distortion and creep at temperatures to which the

material may be subjected under all conditions of use.

All of these factors are to be considered with respect to thermal aging. [UL 886 Sec. 4.3]

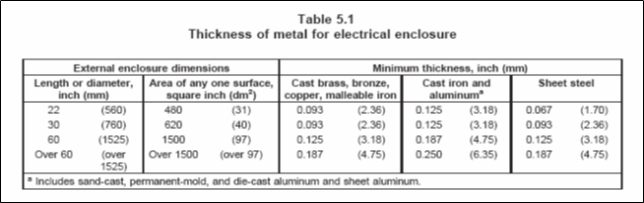

Thickness: The minimum wall thickness of a box or fitting shall not be less than that specified in Table 5.1 (Attachment 1)

Exception No. 1: A flexible fixture fitting need not comply with this requirement.

Exception No. 2: A flexible connection fitting need not comply with this requirement.

Exception No. 3: A mineral insulated cable fitting need not comply with this requirement.

Exception No. 4: The thickness at a bottomed hole in the enclosure need not comply with this requirement. [UL 886 Sec. 5.1]

| A flexible fitting with thin corrugated-metal walls shall have an insulating inner liner to prevent electric arcs from burning through the walls. The insulating liner shall withstand arcing when tested as described in the Arcing Test, Section 23. [UL 886 Sec. 5.2] |

| A flexible fitting shall have approximately the same inside diameter as that of the corresponding trade size of conduit. The inside diameters of an end fitting and an insulating liner shall be approximately the same. [UL 886 Sec. 5.4] |

| New and Unused – Electrical materials shall be new and unused. |

| As Designed – Electrical materials shall be in accordance with the Saudi Aramco-approved project-specific design drawings, diagrams, schedules, lists, databases, and associated documents (in particular, raceway type and trade size as shown on electrical BOM and raceway schedules). |

| Free of Damage – Electrical materials shall be free of damage. |

| QC Before Installation – Electrical materials shall conform to all applicable requirements, standards, and specifications prior to release to be used as part of the work. |

| Identification – Electrical materials shall be identified by using tags, stamps, color coding, stencils or labels. The location and method of identification shall not affect the function or quality of the materials. |

| Traceability – Electrical materials shall be traceable from the manufacturer and supplier through delivery, storage, fabrication, erection, installation, repair, modification and use. |

International Codes & Standards

| 1. UL 886 – UL Standard for Safety for Outlet Boxes and Fittings for Use in Hazardous (Classified) Locations. |

| 2. SAES-P-104 – Wiring Methods & Materials. |

| 3. SAES-P-100 – Basic Power System Design Criteria. |

Table 5.1 – Thickness of Metal for Electrical Enclosure – UL 886