This article is about DC Switchboard & Circuit Breakers Design & Material Selection Guide for commercial buildings, plants and refinery projects.

DC Switchboard & Circuit Breakers Material Selection Guide

| Electrical materials shall be new and unused. |

| Electrical materials shall be in accordance with the approved project-specific design drawings, diagrams, schedules, lists, databases, and associated documents. |

| Electrical materials shall be free of damage. |

| Electrical materials shall conform to all applicable requirements, standards, and specifications prior to release to be used as part of the work. |

| Electrical materials shall be identified by using tags, stamps, color coding, stencils or labels. The location and method of identification shall not affect the function or quality of the materials. |

| Electrical materials shall be traceable from the manufacturer and supplier through delivery, storage, fabrication, erection, installation, repair, modification and use. |

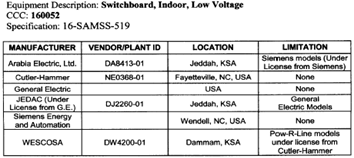

The switchboard shall be from the manufacturers list below: SAES-P-101.

| Switchboards shall be manufactured per (NFPA 70) NEC 384, UL 891 and NEMA PB 2. |

| A space heater system shall not be installed within the switchboard enclosure(s). |

| All conductors (busbars, connectors) shall be made of copper, silver or alloys of these materials. (See exceptions) |

| The switchboard shall be equipped with voltage and amperage indication. (Details at Para. 12.1 and 12.2) |

| Provide White Nameplate with black lettering to identify the Switchboard with the tag number indicated within Data Schedule 1. |

| Switchboards shall: a) be rated for continuous duty b) have rated current- maximum of 2000A c) have short circuit interrupting rating minimum of 10 kA rms |

| The switchboard shall be front accessible, deadfront, completely enclosed, and free standing. |

| Enclosures shall meet the requirements of either Type 1, 2 or 5 per NEMA 250. |

| All joints of the main circuit phase bus system shall be bolted with a minimum of two bolts as follows: |

| For overlapping joints, two bolts shall be provided. |

| For butt joints with splice plates, four bolts shall be provided (i.e., two bolts at each overlap). |

| Bus bar mating surfaces shall be either silver or tin plated. |

| The main circuit bus system shall be of rigid material (i.e., cable or flexible conductors shall not be used). |

| Conductors shall be terminated using either one or two hole, mechanical or compression connectors with the following exceptions: a) All wire/cable connections to the main circuit bus system shall be terminated using two hole compression connectors. b) All wire/cable 250 MCM and larger or 120 mm² or larger shall be terminated using compression connectors. |

SAIC-P-3122 REV 2.xls

| A ground bus shall be provided extending the full length of the switchboard. Bus design shall accommodate the termination of a two hole connector at each end of the bus. |

| Breakers operating at greater than 240 V shall be equipped with padlockable lock-off devices. |

| If an incoming disconnect switch is provided, the switch assembly is not required to be withdrawable providing the open switch poles are visible with the compartment door open. The switch shall be padlockable in the OPEN position. |

SAIC-P-3122 REV 2.xls

| Circuit breakers with frame sizes exceeding 600-A shall be equipped with the following: a) fully field maintainable (e.g., operating mechanism, pole contacts, etc.). b) equipped with a field adjustable electronic trip unit (i.e., “Type A” per NEMA AB1) |

| If a main circuit disconnector is provided, it shall be equipped with the following additional features: a) it shall be withdrawable and padlockable in the fully withdrawn position. In this condition the compartment door shall be able to be closed to prevent a person from contacting any electrically energized parts. b) it shall be equipped with adjustable instantaneous and inverse-time ground fault detection and tripping. |

SAIC-P-3122 REV 2.xls

| Switching assembly spare and space allotment shall be as follows: a) A spare switching device shall be provided for every five devices of the same rating. b) A minimum of one space shall be provided for every ten or portion of ten connected feeder circuits. |

| Ground fault protection shall not be installed on any incoming or outgoing circuits. |

| Main incoming amperage and voltage metering shall be provided for each switchboard assembly. a) Discrete voltmeter(s) shall display a voltage indication of all three phases (alternately). b) Amperage indication shall be provided of all three phases (alternately). |

SAIC-P-3122 REV 2.xls

| Meters shall operate at a maximum voltage of 150 V. |

| Amperage meters shall operate at a maximum current of 25A. |

| Conductors and busbars shall be located so as to be free from physical damage and shall be held firmly in place. NFPA 70, NEC 408.3 (A) (1) |

| All sections of a switchboard shall be bonded together using an equipment grounding conductor sized in accordance with Table 250.122. (NFPA 70, NEC 408. 40) |

Table 250.122 – NFPA 70, NEC

| Load terminals for field wiring, including grounded circuit conductor load terminals and connections to the ground bus for load equipment grounding conductors, shall be located so that it is not necessary to reach across or beyond an uninsulated ungrounded line bus in order to make connections. (NFPA 70, NEC 408.3 (D)). |

| The minimum wire-bending space at terminals and minimum space provided in panelboards and switchboards shall be as required in Table 312.6 (A) and (B). (NFPA 70, NEC 408.55). |

| Circuit directory or circuit identification – Every circuit and circuit modification shall be legibly identified as to its clear, evident and specific purpose or use. (NFPA 70, NEC 408.4). |

| Instruments, pilot lights, potential transformers, and other switchboard devices with potential coils shall be supplied by a circuit that is protected by standard overcurrent devices rated 15 amperes or less. (NFPA 70, NEC 408.52). |

The distance between bare metal parts, busbars, and so forth shall not be less than specified in NEC Table 408.56.

International Standard and Codes for DC Switchboard Panel Design & Material Selection

| NEMA 250 Enclosures for Electrical Equipment (1000 Volts Maximum), 2003 Edition |

| SAES-P-100 Basic Power System Design Criteria |

| SAES-P-101 Regulated Vendors list for Electrical Equipment |

| NEMA PB2 Deadfront Distribution Switchboards |

| NFPA 70 National Electrical Code (NEC) |

| SAES-P-104 Wiring Methods and Materials |

| 16-SAMSS-519 Indoor Switchboard – Low Voltage |