This article is related to electrical engineers, supervisor to make familiar them how to install direct buried cable in plants and process industry as per international standards. Main keywords for this article are Direct Buried Cable Installation Trench Requirements, Direct buried cables Trench Design, Pulling cables into a prepared trench, Compaction and Grading.

Direct Buried Cable Installation Trench Requirements

Direct buried cables may be used only with Company approval. Direct burial cables shall have an armored sheath and an overall PVC jacket.

Direct buried cables Trench Design

a. Cables exiting from main trenches shall be installed in conduit or in lateral trenches.

b. Lateral trenches shall be similar in construction and installation to the main trench.

c. Direct burial cables shall be buried a minimum depth within the trench (grade to top of cables) as specified below:

(i) 600 volts and below cables 610 mm (24 in)

(ii) Over 600 volt – 15 kV cables 610 mm (24 in)

(iii) 35 kV cable 1120 mm (44 in)

Direct buried cable Installation

There are two acceptable methods for installing cables buried directly in the ground:

a. Laying the cables in a prepared trench.

b. Pulling the cables into a prepared trench.

Laying cable in a prepared trench

One method for installing direct-buried cables is to lay them in a prepared trench from a moving vehicle which carries the reel of cable.

a. When cables are installed in this manner caution should be exercised to make certain that the minimum bending radius is not exceeded when the cable is being taken from the reel. (Note: If the reel should

suddenly “spin” due to the weight of the cables a sharp bend may occur directly beneath the reel where the cables contact the bottom of the trench.)

b. In some cases it will be necessary that the cable be ordered with all three conductors paralleled on the same reel.

c. In cases of long runs the conductors may be placed on individual reels to minimize the necessity of splice or termination points.

Pulling cables into a prepared trench

An alternative method for installing cables in a trench is to pull them in.

a. When cables are pulled into a trench a dynamometer shall be used to make certain that the maximum pulling tension is not exceeded if cables are pulled other than by hand.

b. In long runs rollers shall be used to reduce friction.

c. Some “crossing” methods are listed below which may eliminate the need for “conduit sections” to provide physical protection. Where conduit is used, suitable flared fittings shall be used on the ends of the conduit and extreme care shall be used so as not to overbend the cable while pulling through the conduit.

d. Split conduits or open topped raceways are also an option. They can be used to allow the cable to be laid in place and then have the top enclosed. Note: Enclosed wooden raceways shall never be used due to adverse heat-transfer characteristics.

e. All split conduits shall be purchased from a manufacturer and not field fabricated. Split conduits shall have lips and grooves to prevent slippage.

Backfill

- Backfill shall meet the requirements and shall consist of coarse clean sand with no rocks, sharp objects, or any other material or substance which might damage the cable. Thermal resistivity of clean sand shall be no greater than 120°Cocm/W.

- After installation of cables clean compacted thermal sand shall be provided over the top layer of cables. Each layer of sand shall be compacted and rolled to achieve a 95% compaction value.

- A yellow warning tape with black letters (English) shall be provided 150 mm above the red concrete slab.

Marking and Cover

- Marking and cover shall be installed per design documents.

- If not defined on construction documents trench covers shall be:

a. Red-pigmented reinforced concrete, either precast or poured in place. b. Red cement tiles sized 305 mm wide by 305 mm long by 50 mm thick (12″ x 12″ x 2″) shall be installed or 2 inch (50mm) thick red concrete slab shall be poured in a complete layer on top of the sand across the trench. Cover shall extend 305 mm (12 in) beyond the cable on either side of the trench.

c. Removable and supported by the trench walls.

d. Flush at the top with the adjacent paving.

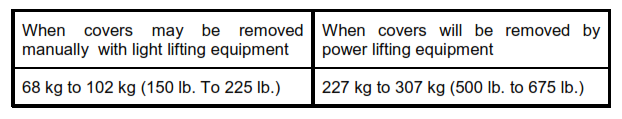

e. Every tenth cover shall have means for the attachment of a lifting device. To facilitate removal, these covers should be limited in mass as follows:

Compaction and Grading

After installation of red concrete covering, the trench shall be filled with sifted sand to within 150 mm (6 in) of grade.

Soil similar to that in the surrounding area shall be used to complete the trench fill. Upon completion, the surface of the trench shall be leveled to match the surrounding grade.

thanks for writing