This article is about Electrical conduit Installation Aboveground & Undergroud Techniques and focusing to the engineers, technicians and supervisors. You will find lot of documents related to this article. Just navigate our website www.paktechpoint.com and find more articles. Please! Do not forget to subscribe our You tube channel also. Thanks in Advance.

PLEASE SUBSCRIBE OUR PAKTECHPOINT YOUTUBE CHANNEL

To ensure that Electrical Conduit Installation is performing safely, efficiently and in accordance with good working practice, as per International standards and Saudi Aramco.

This article is applicable to all PVC, GRS and EMT conduit installation activities, which are to be installed.

Pre-Installation Activities Preparation

1. Electrical materials shall be new, unused and free of damage.

2. Fitting intended to connect to an unthreaded opening in a box or enclosure shall be provided with secure means. A fitting provided with locknut shall have a thread projection, when measured from the shoulder stop to the end of the threads along the major axis of threaded projection.

3. Rigid connector, couplers and stopping plugs shall be made of steel galvanized inside and outside. On conduit runs exceeding 7.5m an inspection installation shall be provided.

4. A threaded hole for connection to conduit that is tapped completely through the wall of box shall permit proper attachment of a conduit bushing to wrench -tightened conduit.

5. Make sure conduit materials are stable when storing or handling. Suitable lifting equipment for heavy lifts shall be used. Manual handling/lifting of smaller bundles

of conduit (i.e., bundles of 1 O or less) shall be applied at a minimum of two points by qualified personnel.

6. Transport and store the conduits and accessories by methods in accordance manufacturer’s instructions to avoid product damage.

8. Store conduits in a planned and orderly manner that does not endanger employee safety. Ensure stacks and tiers are stable and stacked to aid safe handling and loading.

9. Do not store conduits under power lines or where materials may block egress or emergency equipment.

10. Conduits shall be stored in a clean, dry and secure location. Especially avoid places where water might accumulate or where significant dust or dirt is present. If such a location is not available, materials shall be stored on pallets or other means to rise above the floor and possible water levels, and wrapped in protective plastic sheeting at both ends of the bundle.

11. Should any event such as water leaks occurs, that could damage stored materials, the affected material shall be re-inspected for damage and necessary replacement shall be obtained.

12. Place steel conduit bar stock in racks or stack and block them on a firm, level surface to prevent spreading, rolling, or falling. Use either a pyramided or battened stack. Step back battened stacks at least one unit per tier and securely chock them on both sides of the stack.

13. Place or store materials so they do not interfere with access ways, doorways, electrical panels, fire extinguishers, or hoist ways. Do not obstruct access ways or exits with accumulations of scrap or materials. Aisles must be wide enough to accommodate forklifts or firefighting equipment.

14. Store conduits inside buildings under construction at least 6 feet away from any hoist way or inside floor openings, and 10 feet away from an exterior wall that does not extend above the top of the material stored.

15. Unload conduits so that personnel are not exposed to the unsecured load. PVC coated rigid steel conduit shall be handled in manners that prevent injury to the PVC coating by stones and any other material.

16. Touch-up damaged factory finished surface. Use touch-up materials to match original. Do not paint over markings or labels.

17 PVC materials not identified as “sunlight resistant” shall be stored in areas shaded from direct sunlight.

18. Manufacturer’s recommendation will be followed in threading and bending of PVC coated, GRS conduits.

19. Conduit ends shall be sealed with duct seal or end bells wherever it’s required and applicable.

20. Follow Conduit run to be completed and cleaned of construction debris by blowing with clean air prior to Cable Pulling.

Installation Activities (Above Ground RGS Conduit Installation)

1 Fabricate and install braces and supports. Welding shall be in accordance with approved procedures. Welding of braces and support should be sealed and full weld. Clean and properly primed all weld supports.

1 Lay RGS (Rigid Steel Galvanized) conduit using adequate tie wires as temporary supports. Ensure correct fittings, offsets, route and elevation. Mark the required location of supports as shown on plan drawings.

2 Check Maximum total bend radius for each conduit. Run shall not contain 4-90° (total of 360°) between pull points e.g. conduit bodies and boxes.

3 Left all empty conduits with nylon pull cord.

4 Install Conduit parallel with or at right angles to walls, columns, beams etc.,except as indicated on drawings.

5 After cutting of conduit pipes, remove any sharp burrs using a half round file.

6 Lubricate threads of plugs, junction boxes and other fittings with rust preventive grease compounds.

7 Care should be taken to avoid wrench damage to conduit coating during tightening.

8 Field cut of metal support, and exposed conduit thread should be touch-up with zinc rich paint.

9 Provide Sealing for all conduit wall penetration, penetration of conduit should be thru metal sleeve, sealing should be same as the rating of the wall.

10 Install metal junction boxes levelled and supported with appropriate hubs, locknuts and bushings.

11 Install Conduit bodies and Pull Boxes in a vertical manner position.

12 Raceway shall be provided with expansion fittings where necessary to compensate for thermal expansion and contraction.

13 Install the conduit drain fittings at the lowest elevation of the installed conduits in order to drain the accumulated liquids that might occur due to condensation which is known to be a problem when raceway was exposed to different temperatures.

14 Conduits that cross hazardous location boundaries shall terminate in the open air at both ends of the conduits.

15 Small gap shall be allowed between cable tray ends and conduit openings applicable to be dropped in conduits.

16 Conduit fill shall not exceed the maximum fill as specified in NEC Chapter 9″. 6.3.17 Installed conduit stub-up to be protected, open ends plugged, bends free of deformities, and hard plastic conduit spacer installed as required.

Activities (PVC Coated -RGS Conduit Installation):

1. PVC-Coated GRS Conduit Exterior Coating: The PVC coating shall be free of blisters, bubbles, and pinholes. The PVC coating shall be continuous over the entire length of the conduit except at the threads, and shall be holiday-free at the time of manufacture.

2. PVC-Coated GRS Conduit Coating – The inside of the PVC-coated conduit, couplings, and elbows shall be free of the PVC coating material. All sleeve extensions shall be square cut.

2. PVC-Coated GRS Conduit Adhesion Test: The adhesion of the PVC coating to the conduit shall be greater than the strength of the coating itself. This shall be determined by making two circumferential cuts, above 1/2 in. (12.7 mm) apart, through the plastic to the substrate. A third cut shall be made perpendicular to and crossing the circumferential cuts. The edge of the plastic shall be carefully lifted with a knife to form a plastic tab. This tab shall be pulled perpendicular to the conduit with a pair of pliers. The plastic tab shall tear rather than any additional coating film separating from the substrate.

3. PVC-Coated GRS Conduit: Any supplemental interior coating shall be smooth and continuous and shall be unaffected by heat of the exterior coating process.

4. PVC-Coated GRS Conduit Couplings: Each coated coupling shall have a flexible PVC sleeve which extends from each end of the coupling and which will overlap the PVC coating on the conduit when the coupling has been installed on the conduit.

Installation Activities (EMT Conduit)

1. EMT shall be listed as meeting the requirements of ANSI C80.3. Free of Damage – Electrical materials shall be free of damage.

2. Circular cross section: Electrical metallic tubing shall have a circular cross section sufficiently accurate to permit the application of identified EMT fittings.

3. Protective coating for corrosion resistance:

1. The exterior surface shall be either thoroughly and evenly coated with metallic zinc or protected with an ACRC.

2. The interior surface shall be protected by a zinc or an organic coating. The interior coating shall have a smooth continuous surface. An occasional variation due to uneven flow of coating shall be acceptable.

Below Grade PVC Conduit Installation:

- Check the exact location where the direct buried conduits are to be installed in accordance with the IFC drawing.

- Before any installation of underground conduit, verify the designated area is clear of underground cables.

- Excavation and backfill shall be carried out in accordance with SAES-P-104 (ARAMCO STANDARD).

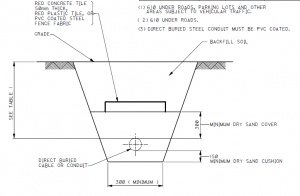

- Depth of conduit below the grade must be as per the drawing, specifications and standard.

- Direct buried conduit shall be PVC conduit Type DB-120 per NEMA TC-2.

- Installed the conduits at locations indicated in the IFC drawing.

- Conduit shall be equipped with complete fittings as required.

- Installed conduit stub-up to be protected, open end plugged, bends free of deformities, and hard plastic conduit spacers installed as required.

- Distance between the stub up conduits and concrete walls ring shall be maintained.

- Number and Sizes of PVC stub up conduits shall be as per IFC, index P or J, Cable route drawings.

- Install the precast 50 mm thick red concrete tiles 300 mm above direct buried conduit in accordance with Standard following Drawing.

- In addition, a yellow warning tape shall be installed over the tiles.

- The end(s) of ducts and conduit terminating below grade or in open air shall be sealed with duct sealing putty or end bells wherever its required and applicable.

- Conduit run must be completed and cleaned of construction debris by blowing with clean air prior to cable pulling.

- The number of conductor shall not exceed the maximum fill specified in NEC Chapter 9.

- Prior to the cable pulling activities ensures that duct bank and conduit raceway is clean and free from foreign object and debris.

- Pull cables and wires into the conduit or cable duct by ropes with basket grip with the application of pulling compound to prevent damage to cable insulation.

- After the cable are pulled to its intended equipment, ample allowance must be provided prior of cutting these cables. Tape the cutting end with a rubber tape then followed with plastic tape to prevent moisture and dirt until such time glanding and termination will be performed.

- The end(s) of duct and conduits terminating below or in open air shall be sealed with sealing putty or an equivalent compound.

- Mark the location of underground Conduit in accordance with Standard Drawings AB-036273 or AB-036326.

- As per NEC 300.5 (D) (4) where the enclosure or raceway is subject to physical damage, the conductors shall be installed in rigid metal conduit, schedule 80 PVC conduit, or equivalent.

- Underground conduit installation shall be as per SAES-P-104 section 8.1.1

- Minimum depth of burial requirements from grade level to the top surface of cable, conduit or duct bank shall be as per SAES-P-104 section 10.1

- Direct buried cables and conduits shall be installed in a single layer, except where rearrangement is necessary at transitions to multi-layer concrete encased duct banks or for entering building as per SAES-P-104 10.14

- Cable separation shall be as per SAES-P-104 section 14 and underground cable system shall be as per SAES-P-104 section 10.

- Cables crossing pipeline corridors shall be installed in accordance with SAES-B-064 as per SAES-P-104 section 10.12

- As per SAES-B-064 section 7.8.2(b), Electrical cables that cross a pipeline corridor shall be installed at least 1 meter under the pipelines in duct banks per SAES-P-104.

- Installation of cables in outdoor concrete-walled trenches with metal or concrete slab covers is not permitted as per SAES-P-104 section 10.15

As per NEC 300.5(F), Backfill that contains large rocks, paving materials, cinders, large or sharply angular substances, or corrosive material shall not be placed in an excavation where materials may damage raceways, cables, or other substructures or prevent adequate compaction of fill or contribute to corrosion of raceways, cables, or other substructures.

PVC conduits shall not be extended above grade in industrial facilities. Where above grade extensions of buried PVC conduits are required, a transition shall be made underground, using threaded PVC to rigid metal conduit adapters as per SAES-P-104 section 10.5.

REFERENCES for Electrical conduit Installation

- NFPA 70 National Electrical Code (NEC)

- NFPA 72 National Fire Protection Association, 2010 Edition

- NEMA RN 1 Polyvinyl-Chloride (PVC) Externally Coated Galvanized Rigid Steel Conduit and Intermediated Metal Conduit

- NEMA TC 2 Electrical Polyvinyl Chloride (PVC) Conduit

- NEMA TC 3 PVC Fittings for Use with Rigid PVC Conduit and Tubing

- NEMA TC 6 & 8 PVC Plastic Utilities Duct for Underground Installations

- NEMA TC 9 Fittings for PVC Plastic Utilities Duct for Underground Installation

- ASME B1.20.1 Pipe Threads, General Purpose (Inch)

- UL Underwriters Laboratories

- CSA Canadian Standards Association

- ANSI C80.1 Rigid Steel Conduit – Zinc Coated

Tools and Equipment Electrical conduit installation

-Drilling Machine

-Welding Machine

-Pipe Threading Machine -Hydraulic Pipe Bender -Pipe Wrench

-Speed Cutter

-Face shields

-Grinding machines/ disc -Forklift

-Stake bed Truck

-Flat and Half round file -Other relevant tools

Please read also: QA QC NOTES ELECTRICAL AND INSTRUMENTATION (STANDARD: ARAMCO, IEEE, IEC, NEC, NFPA ETC.)