EQUIPMENT SELECTION FOR MAGNETIC PARTICLE TESTING

Magnetic particle testing equipment range from heavy, complex automated handling systems weighing several tons to small, lightweight portable units. The following are requirements to be considered when selecting equipment for magnetic particle testing.

1 . Wet or dry method.

2. Magnetization method (alternating current, direct current or both; coil or induced; yoke; or permanent magnet).

3. Degree of automation.

4. Incorporated or separate demagnetization capability.

5. Amperage required.

6. Tank capacity for wet horizontal equipment.

7. Air and water supply requirements.

8. Line voltage requirements.

9. Accessories required.

10. Indication detection and recording.

11 . Technician requirements.

12. Mobile or stationary equipment.

Purpose of Test

Objects are typically tested to a specification. The certified Level III magnetic particle testing technician should be consulted and an appropriate specification selected.

Area Tested

Instructions prepared or approved by a Level III technician will define the area to be tested. Reporting should be done in accordance with contract document or written instructions provided by the Level III technician. Level I nondestructive testing personnel may not accept or reject test objects. Under direction of Level II or Level III personnel, Level I personnel may operate magnetic particle test equipment.

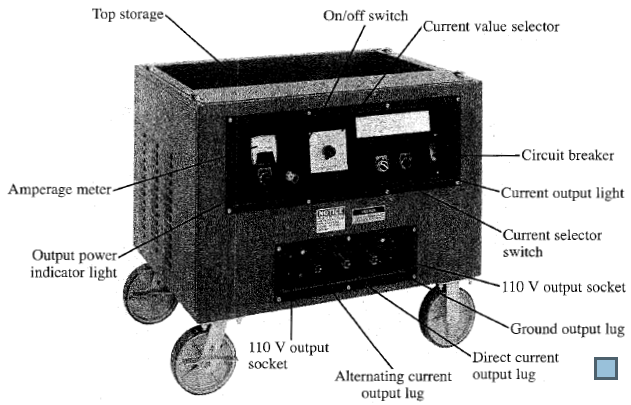

Mobile magnetic particle test equipment

A typical mobile magnetic particle testing system is shown in Figure. Location and nature of test object, size and test methods all are factors that determine whether or not the equipment will be brought to the test object, the test object will be brought to the equipment, the test will be done manually or the test will be automated to handle many similar test objects.

Particles Used

In magnetic particle testing, the particles have the ability to be strongly attracted to leakage fields. The particles may be in the form of a dry powder, or they may be suspended in a liquid carrier. Additionally, these particles have carriers, air, dry gases, water or oils that are related to the probability of detection, the gage repeatability and reliability value of the magnetic particle method selected for particular types of test objects.

STATIONARY TESTING EQUIPMENT

A typical stationary horizontal wet magnetic particle testing unit of intermediate size is shown in Figure. The unit has two contact heads for either direct contact or central conductor circular magnetization using a copper rod between the heads or a cable connected to a contact block between the heads.

Many such units contain a coil used for longitudinal magnetization. The coil and one contact head are movable on rails. The other contact head is fixed; the contact plate on it, being air cylinder operated, provides a means for clamping the test object. The unit has a self contained power supply with all the necessary electrical controls.

Magnetizing currents are usually three phase full wave direct current or alternating current, depending on usage requirements. The units are made in several sizes to accommodate different length test objects and with various maximum output currents. A full length tank with pump, agitation and circulating system for wet testing media is located beneath the head and coil mounting rails. A hand hose with nozzle is provided for applying the bath. On special units, automatic bath application facilities are provided.