1. PURPOSE

2. SCOPE

3. REFERENCE

4. RESPONSIBILITY

5. PROCEDURE

6. SAFETY PRECAUTIONS

7. ATTACHMENT

1.0 PURPOSE

The purpose of this procedure is to provide work methodology, guidelines, and quality requirements for the execution of Flange bolting as per international codes, Standard and Specification covered under Plants and refinery projects.

2.0 SCOPE

The scope applies to flange bolting works for above ground piping installation as described in the scope of work for Plants and refinery projects.

3.0 REFERENCES

SAEP-351 Bolted Flange Joint Assembly.

SAES-L-100 Applicable Codes & Standards for Pressure Piping System.

SAES-L-109 Selection of Pipes Flanges, Bolts and Gaskets.

SAES-L-450 Construction of On-Land and Near Shore Pipelines.

G.1.2.100 Work Permit System.

Saudi Aramco Approved Construction Drawings.

SATIP Saudi Aramco Typical Inspection Plan

SAIC-L-2014 Saudi Aramco Inspection Checklist- inspection of Bolted Flange Joint Assy.

SATR-L-2001 Saudi Aramco Test Report – Flange Joint Tightening Inspection Report

Saudi Aramco Typical Inspection Plan

SA TIP-L-050-01 I SATIP-L-050-02

SA TIP-L-350-02 / SA TIP-L-350-05

4.0 RESPONSIBILITIES

4.1 Construction Manager is responsible to oversee that all material, manpower and equipments required during this activities are being carried out in accordance with project specification, drawings and standards and is responsible for implementing all HSE requirement.

4.2 Construction Supervisor is responsible to monitor that project scope activities is properly implemented and carried out as per project scope and standard and shall monitor availability of materials, manpower and equipment.

4.3 Construction Foreman is responsible in manning manpower and equipment and shall ensure that all activities are carried as per project drawing scope and standards.

4.4 QC Manager is responsible in the implementation of company project quality management and ensure that all standards and specification are being carried out and complied as per Saudi Aramco requirements.

4.5 QC Inspector shall be responsible in monitoring and verifying quality requirements as to actual inspection and shall ensure that inspection are canied out in conformity with project procedure, standards and specifications.

4.6 Safety Officer shall be responsible in monitoring all safety precautions measures at sites such as banicades and safety signage to ensure a safe working environment. Monitor and verify availability and valid work permits prior to any work commencement.

5.0 FLANGE BOLTING PROCEDURE AND METHOD STATEMENT

5.1 Pre-Assembly Inspection:

5.1.1 QC piping Inspector shall verify gasket for correct type, rating, dimension and compatibility with the flange facing. Ensure gasket is free from any damageparticularly in the seating element. Ensure that spiral wound gaskets are stored flat especially for larger sizes, 24 inches and above.

5.1.2 Bolts and washers shall be visually checked for proper size, grade, and dimension and for any physical damage or shanks or threads which would affect the bolt assembly or performance. Check the suitability of the stud bolts and nuts material for the service temperature and the compatibility with the flange material.

5.1.3 Visual examination on flange faces, particularly the seating area for cleanliness and ensure no damage such as scratches and any sign of deformities cause of mishandling is present.

5.1.4 Ensure that the lubricant for bolts and nuts are lubricants listed in table of SAEP-351-01.

5.1.5 Check tightening tools for adequacy, performance and calibration as maybe required.

5.1.6 Verify that the lubricant is not used on the gasket seating area and flange shielding is installed as maybe required.

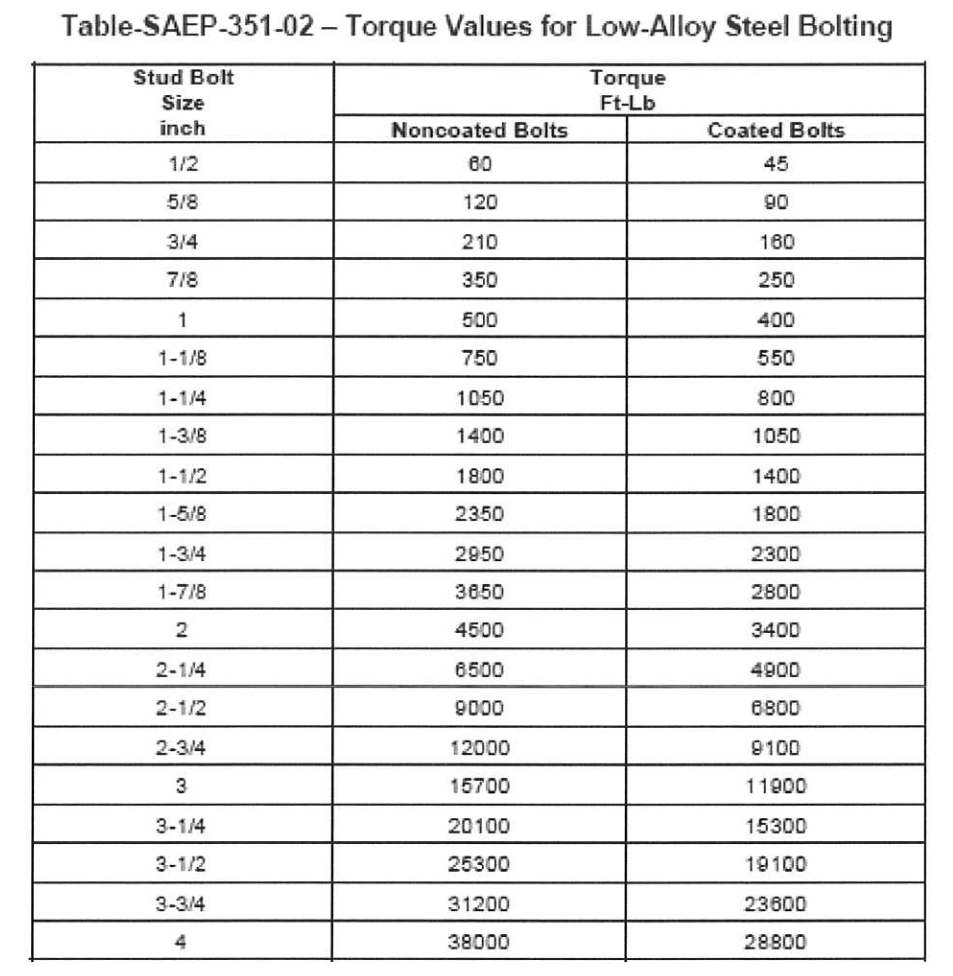

5.1.7 Ensure that torque value is in accordance with the flange rating, bolt size, type of gasket and friction factor of the thread lubricant. Please refer to attached Table of SAEP-351 02 and SAEP-351-03 for Torque Value specification to be applied.

Table-SAEP-351.02 — Torque Values for Low-Alloy Steel Bolting

Notes:

1) Torque values are based on 50000 psi prestress on stud bolts and Friction Factor of 0.16 for noncoated surfaces and 0.12 for new coated surfaces. A combination of various elements such as the conditions of the threads. the condition of the flange to the nut bearing surface and the type of lubricant used, makes up the friction factor which can vary from .04 to .20 or as much 3s 500%

2) Torque values for stainless steel or other alloy stud bolts can be obtained by multiplying the ratio of the specified minimum yield strength (SMYS) of stainless steel stud bolts to A193 BT stud bolts, to the torque values in the Table-SAEP-351-02. The SMYS values for all bolting materials are listed in ASME B31.3 code (Note: SMYS depends on grade, class and size)

5.1.8 Hydra tight project such as HTF Bolt Tensioners, Successor Vacuum Retract-Bolt Tensioners and Torque Wrenches shall be used during bolt tensioning. Construction Supervisor in coordination with QC Piping Inspector shall identify the tools to be use prior to commencing the erection and installation of piping.

5.1.9 Saudi Aramco Inspection Checklist (SAIC-L-2001) shall be use to document this procedure.

Note: Saudi Aramco Inspection checklist needs to be filled out prior to the issuance of RFI- Request for Inspection.

5.2 Bolt Tightening Procedure

5.2.1 Align flanges and gasket. Forced tightening is not allowed to overcome non acceptable alignment tolerances. Clamp securely in place.

5.2.2 Apply lubrication as per attached table ofSAEP-351-01 to stud threads over length and nut engagement and to face of nut which contacts flange. Ensure that the nuts run freely down the thread of the studs.

5.2.3 Install all studs and nuts by hand tight and ensure that studs pass freely through the flanges holes. Position the nut on one end of the stud such that only the crown of the stud projects beyond the face of the nut. The excess stud length should project beyond the nut on the other side.

5.2.4 Number each stud according to its position in the flange as shown on attached table figures of SAEP-351-01 “Stud Bolt Tightening Sequence”, and tighten studs per stud bolts tightening sequence with air impact wrench or equal.

5.2.5 For joints containing RTJ or Spiral Wound Gaskets, repeat step as specified in item 5.2.4

5.2.6 Tighten the stud bolts on stages to obtain the final required torque from the appropriate table of SAEP-351. The first stage should not be more than 30% of the final torque. Final torque shall be within pl us or minus 5% of the Required Torque Value.

5.2.7 Apply the torque evenly to each stud following the stud bolt tightening sequence. The final torque must be within plus or minus 5% of the required values per item 5.2.4.

5.3 Additional Stud Bolt Tightening Procedure in Case of Leaks Occur During Pressure Testing:

5.3.1 In case of leaks, depressurize the piping system to zero psi and re-torque stud bolts to maximum torque value as shown on Table of SAEP-351.

5.3.2 Ifleaks does not stop after re-applying torque has been performed, disassemble the flange joint and inspect as follows:

5.3.2.1 Inspect stud bolts and nuts for defects or damage to threads or improper cleaning of threads.

5.3.2.2 Inspect flange faces for damage and/or misalignment.

5.3.2.3 Inspect gasket for damage or defects.

6.0 SAFETY PRECAUTIONS.

6.1 Approved work permit shall be obtained prior to the start any works.

6.2 Work execution shall be carried out in accordance with this method of statement.

6.3 Work crew must carry out a safety risk assessment prior to the start of any new activities.

6.4 The necessary manpower inclusive of supervisory staff, tools, equipment, materials, and

other resources required must be made available and ready to use.

6.5 Workers shall be provided with and wear their PPE’s needed for work.

6.6 Man lift equipment, if required shall be tested and certified by Saudi ARAMCO Equipment Inspection Division.

6. 7 Only Saudi Aramco certified man lift operator(s) shall be allowed to operate the man lift equipment.

6.8 Sufficient lightings shall be provided if work is done at night time. Work at night shall be approved by client

7.0 ATTACHMENTS

7.1 JOB SAFETY ANALYSIS (JSA)