This article is about Flexible Metal Conduit (FMC) Material Selection Guide & Technical Specification for commercial buildings, plants and refinery projects as per international codes and standards. FMC and associated fittings shall be listed as meeting the requirement of UL 1. [NFPA 70, NEC 348.6]

Flexible Metal Conduit (FMC) Material General Requirements

Minimum Size: FMC less than metric designator 16 (trade size 1⁄2) shall not be used unless permitted in 348.20(A)(1) through (5) for metric designator 12 (trade size 3⁄8).

(1) For enclosing the leads of motors as permitted in 430.245(B)

(2) In lengths not in excess of 1.8 m (6 ft) for any of the following uses:

a. For utilization equipment

b. As part of a listed assembly

c. For tap connections to luminaires (lighting fixtures) as permitted in 410.117(C)

(3) For manufactured wiring systems as permitted in 604.6(A)

(4) In hoistways as permitted in 620.21(A)(1)

(5) As part of a listed assembly to connect wired luminaire (fixture) sections as permitted in 410.137(C)

[NFPA 70, NEC 348.20 (A)]

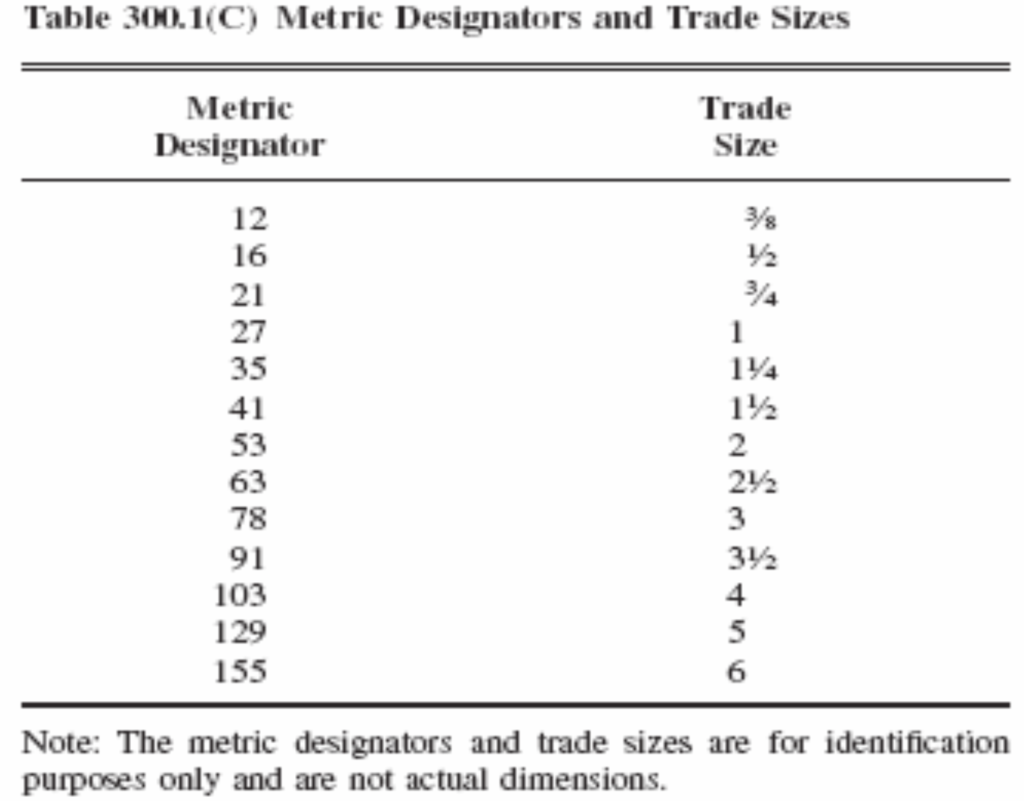

Maximum Size: FMC larger than metric designator 103 (trade size 4) shall not be used. FPN: See Table 300.1(C), Attachment 1, for the metric designators and trade sizes. These are for identification purposes only and do not relate to actual dimensions.

[NFPA 70, NEC 348.20 (B)]

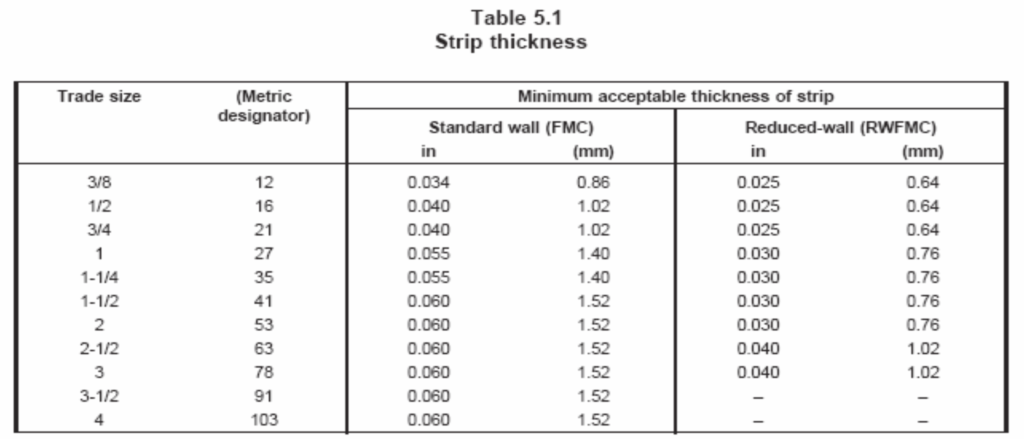

Thickness of Strip: The thickness of the metal strip used for flexible metal conduit shall not be less than indicated in Table 5.1 (Attachment 2) for the specified conduit type.

Exception: The thickness of the metal strip may be less than indicated in Table 5.1 when the conduit complies with the requirements specified for extra reduced-wall flexible metal conduit (XRWFMC).

[UL 1 Sec. 5.1]

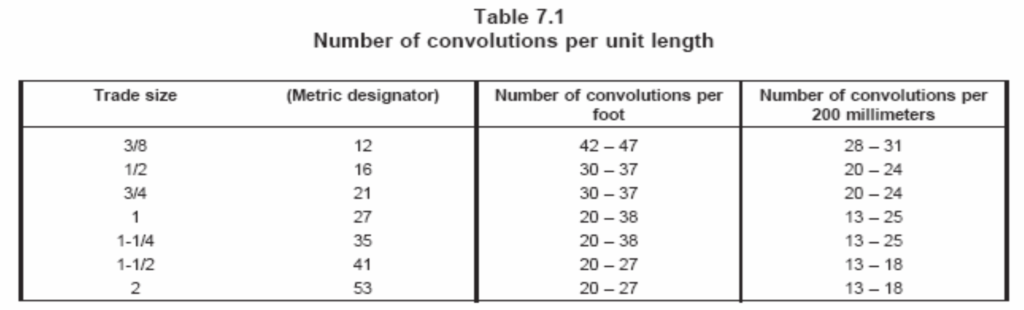

Convolutions: Finished flexible steel and aluminum conduit shall have the number of convolutions per foot or the number of convolutions per 200 millimeters indicated in Table 7.1 (Attachment 3).

[UL 1 Sec. 7.1]

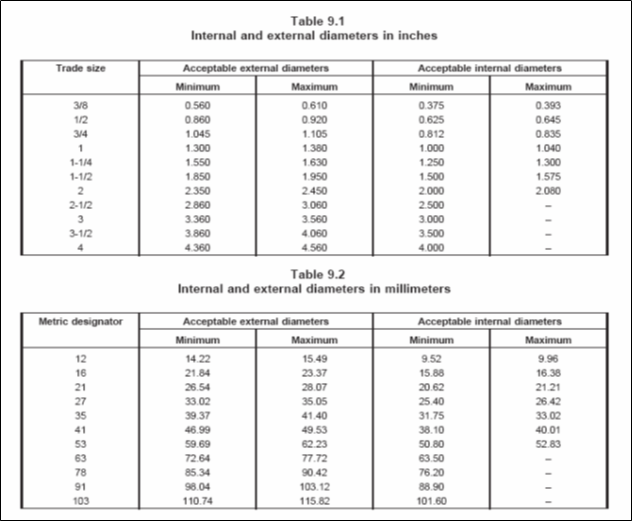

Conduit Diameters: Finished flexible steel and aluminum conduit in trade sizes 3/8 – 4 shall have an external diameter that is not smaller than indicated in the second column and not larger than indicated in the third column of Table 9.1 (dimensions in inches) or Table 9.2 (dimensions in millimeters) and shall have an internal diameter that is not smaller than indicated in the fourth column of Table 9.1 (dimensions in inches) or Table 9.2 (dimensions in millimeters). Finished flexible steel and aluminum conduit in the 3/8 – 2 trade sizes shall have an internal diameter that is not larger than indicated in the fifth column of Table 9.1 (dimensions in inches) or Table 9.2 (dimensions in millimeters). (See Attachment 4) [UL 1 Sec. 9.1]

Conduit Diameters: Compliance of the 3/8 – 2 trade sizes with the minimum and maximum internal diameters in Table 9.1 or 9.2 is to be determined by means of the go and no-go limit gauges specified in Figure 9.1 and Table 9.3. Compliance of the 3/8 – 2 trade sizes with the maximum external diameter in Table 9.1 or 9.2 is to be determined by means of a vernier caliper or its equivalent. Compliance of the 2-1/2 – 4 trade sizes with the maximum external and minimum internal diameters in Table 9.1 or 9.2 is to be determined by means of a vernier caliper or its equivalent. (See Attachment 4 & 5)

[UL 1 Sec. 9.2]

| New and Unused – Electrical materials shall be new and unused. |

| As Designed – Electrical materials shall be in accordance with the Saudi Aramco-approved project-specific design drawings, diagrams, schedules, lists, databases, and associated documents (in particular, raceway type and trade size as shown on electrical BOM and raceway schedules). |

| Free of Damage – Electrical materials shall be free of damage. |

| QC Before Installation – Electrical materials shall conform to all applicable requirements, standards, and specifications prior to release to be used as part of the work. |

| Identification – Electrical materials shall be identified by using tags, stamps, color coding, stencils or labels. The location and method of identification shall not affect the function or quality of the materials. |

| Traceability – Electrical materials shall be traceable from the manufacturer and supplier through delivery, storage, fabrication, erection, installation, repair, modification and use. |

| Markings: If the organization responsible for the conduit produces flexible steel conduit or flexible aluminum conduit in more than one factory, all of the conduit that is produced by or for that organization shall be identified as the product of a particular factory. The factory identification shall be permanent and shall consist of a letter or symbol indented into or embossed on the outer surface of the conduit at intervals no longer than 12 inches (305 mm). The absence of this marking may be used to identify one factory. The meaning of each identification shall be made available. [UL 1 Sec. 17.1.2] |

| Tag: The following statement or its equivalent shall be marked on a tag attached to each coil of aluminum or steel reduced-wall flexible metal conduit (RWFMC) or extra reduced-wall flexible metal conduit (XRWFMC). “When applying setscrew-type connectors, care should be taken not to damage the conduit”. [UL 1 Sec. 17.3.1] |

| Reduced-wall conduit (RWFMC): In addition to the marking requirements in 17.1.1 – 17.3.2, reduced-wall flexible metal conduit (RWFMC), shall be marked by indent printing or embossing with the letters “RW”, and the tag attached to each coil shall have the statement “Reduced-wall flexible (aluminum or steel) conduit” or the equivalent. [UL 1 Sec. 17.4.1] |

Extra reduced-wall conduit (XRWFMC): In addition to the marking requirements in 17.1.1 – 17.3.2, extra reduced-wall flexible metal conduit (XRWFMC) shall be marked by indent printing or embossing with the letters “XRW”, and the tag attached to each coil shall have the statement “Extra reduced-wall flexible (aluminum or steel) conduit” or the equivalent. [UL 1 Sec. 17.5.1]

Each coil of flexible steel and aluminum conduit shall be marked or tagged to indicate the following plainly:

a) The name of the manufacturer, that manufacturer’s trade name for the conduit, or both, or any other acceptable distinctive marking by means of which the organization responsible for the conduit can readily be identified.

b) The date of manufacture by month and year

c) The trade size of the conduit

d) Use only with connectors intended for this type of conduit. ” Cartons for these connectors are marked [UL 1 Sec. 17.3.2]

International Codes & Standards

| 1. NFPA 70 – National Electrical Code, 2008 Edition. |

| 2. UL 1 – Standard for Flexible Metal Conduit. |

Table 300.1C – Metric Designators and Trade Sizes – NFPA 70

Table 5.1 – Strip Thickness – UL 1

Table 7.1 – Number of Convolutions per Unit Length – UL 1

Table 9.1 & 9.2 – Internal and External Diameters of Conduits – UL 1

Figure 9.1 & Table 9.3 Diameter of Internal Diameter Limit Gauges – UL 1