This article of Flow Measurement. It describes Flow Nozzles, discusses their application, suitability, advantages, and disadvantages compared to the more common Orifice Plate metering method. Also listed are precautions to be observed in their application. Main keywords for this article are Flow Nozzle Design Requirement. Flow Nozzle Application. Flow Nozzle Advantages. Flow Nozzle Disadvantages. Flow Nozzle Installation.

Reference is made in this article to the following documents.

American Society of Mechanical Engineers (ASME)

“Fluid Meters, Their Theory and Application” 6th Edition, 1971, pages 232 and 233

Flow Nozzle Design Requirement

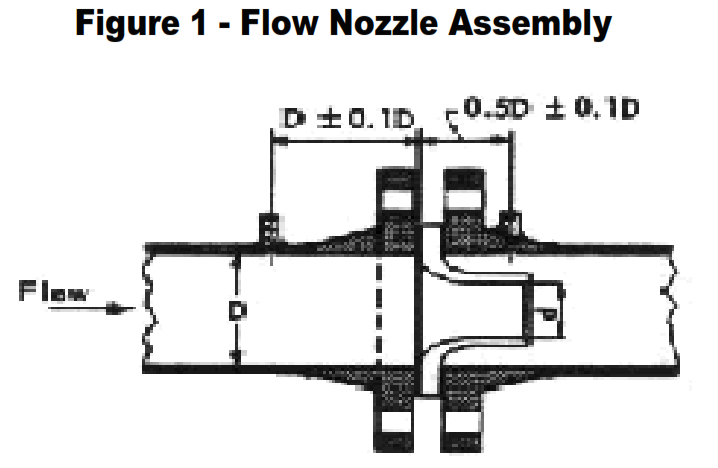

- The Flow Nozzle consists of a restriction with an elliptical contour approach section, see Figure 1. It is a head (differential pressure) producing primary flow element intended for use with indicating, transmitting, totalizing, or combinations of secondary instruments accepting differential-pressure input. A measure of the differential pressure created across the flow nozzle is a measure of flow rate.

- The differential-pressure measurement taps usually are located one pipe diameter upstream and one-half pipe diameter downstream from the inlet face of the nozzle.

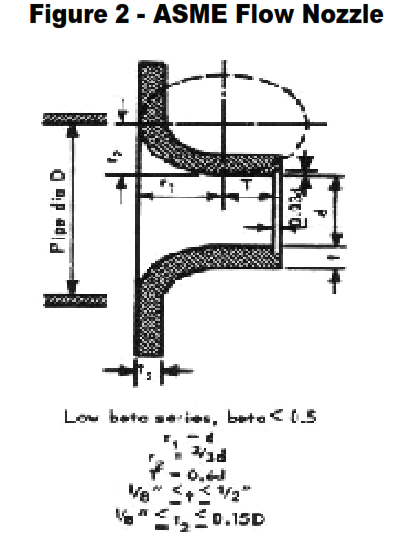

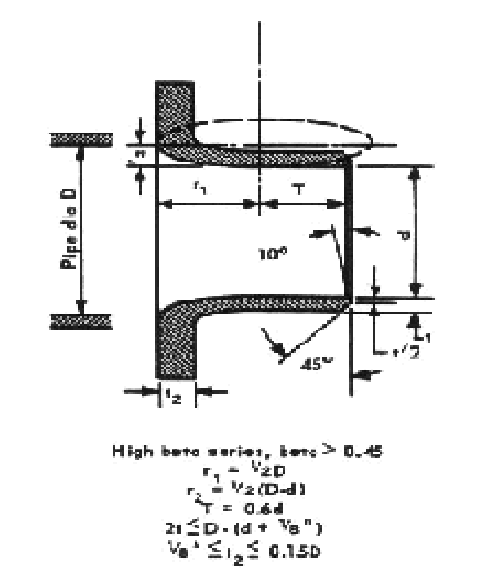

- There are three generally accepted standard designs which differ in the detail of approach section contour and throat length. However, differences in performance are almost indistinguishable. The design commonly used is the long-radius ASME flow nozzle. This nozzle comes in two versions known as low beta and high beta ratio designs. High beta nozzles are recommended for diameter ratios between 0.45 and 0.80. Low beta nozzles are recommended for diameter ratios between 0.20 and 0.50. For beta values between 0.45 and 0.5, either design may be used.

- Flow nozzles may be manufactured from any material that can be machined. Typically they are fabricated from stainless steel or chrommoly steel. Fluid contact surface finishes in the order of 6-10 microinches result in more predictable nozzle coefficients and high repeatability of measurement. The outlet or the discharge side is normally beveled and is one of more critical points of manufacture.

- Where the 10-degree back angle meets the throat bore, the edge must be sharp. Particular care must be taken to avoid taper and out-of-roundness of the throat.

- High-pressure, high-temperature applications (flange rating above ANSI 600 lb Class) may require the welded construction shown on Figure 3. In this case, the procedure is to install and drill the two pressure taps first, then to locate the nozzle in proper relation to the taps and secure it in line with a welding ring. Drill and tap the line and nozzle at four points and thread in machine screws to prevent the nozzle from turning.

Flow Nozzle Application

- Accuracy of the coefficient of a flow nozzle determined from physical dimensions is less than that of an orifice. For high Reynolds number (more than 33,000 times pipe diameter), beta ratio between 0.30 and 0.70, and 6 in to 12 in pipe size, the standard deviation taken from test data is about 0.50 percent. This increases to 1.50 percent for 2-inch pipe.

- The smoothness of the nozzle affects both coefficient and Reynolds number. A rough finish tends to reduce the change of coefficient with change in Reynolds number, but may require flow calibration for accurate determination of coefficient. With actual flow calibration at operating conditions, accuracy is limited primarily by accuracy of calibration facilities.

- The following factors are in common with orifice plates

- Since flow rate is proportional to the square root of the pressure drop, the calibration curve is non-linear and the useful measuring range is limited to about 3 to 1 turndown. Pressure drop increases rapidly as flow rate increases.

- For the same flow and differential pressure, the flow nozzle has approximately the same permanent pressure loss as the orifice plate.

- Requires similar straight runs of pipe or straightening vanes up-stream or downstream.

- Flow-nozzle characteristics are well known and predictable over a moderate range of sizes.

- Flow nozzles are used essentially for the same applications as orifice plates although they are not as economical or convenient. Usually, nozzles are used for higher capacities, where high-viscosity fluids are encountered, or for measuring slurries containing high concentrations of entrained solids, or sediment.

- Flow nozzles are used commonly for measurement of steam flow and other highvelocity fluid flows where erosion may be a problem. Since the exact contour is not particularly critical, the flow nozzle can be expected to retain precise calibration for a long time under adverse conditions.

- The incompressible and compressible flow equations presented for orifice plates are directly applicable for flow nozzles as well.

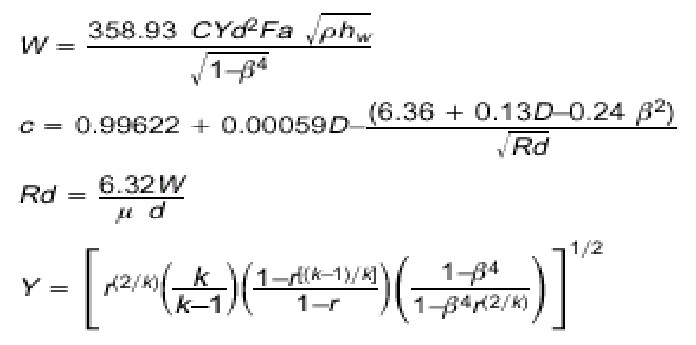

- For convenience, the following equations are furnished for the flow nozzles shown on Figures 1 and 3. The equations are from ASME “Fluid Meters”. where

- C = Discharge coefficient, dimensionless D = Pipe inside diameter, inches

d = Throat diameter, inches

Fa = Area thermal expansion factor, ratio

h = Differential pressure, inches of water

k = Ratio of specific heats: C p / C v

r = Pressure ratio: absolute inlet pressure/absolute outlet pressure

W = Flow rate, pounds/hour

β = Beta, throat diameter/pipe diameter, d/D

P = Density, inlet conditions, pounds/cubic ft

Flow Nozzle Advantages

- The flow nozzle is superior to the orifice for nonhomogeneous fluids. Because of its streamlined contour, it tends to sweep solids through the throat. Similarly, it is suitable for metering wet gases.

- The flow nozzle will pass almost 60 percent more fluid that an orifice with the same diameter and the same differential pressure. This is a distinct advantage for measurement of high-velocity fluids. It has the advantage of operating acceptably over the wide beta ratio range of 0.2 to 0.8. Because of its rigidity, it is dimensionally more stable at higher temperature and velocities than an orifice plate.

Flow Nozzle Disadvantages

- Since the flow rate is proportional to the square root of the pressure drop, the calibration curve is quadratic, limiting measuring range to about 3 to 1.

- The flow nozzle is impractical for systems with low static pressure. Since the differential pressure varies as the square of the flow rate, the pressure drop increases rapidly as the flow rate increases.

- The flow nozzle is expensive to fabricate.

- Flow nozzles cannot be fabricated or duplicated at the plant.

- Modifying an existing flow nozzle to increase capacity is difficult and impractical.

- Straight runs of pipe upstream and downstream of the flow nozzle are required.

- The permanent pressure loss is high, almost as high as that for the orifice plate.

Flow Nozzle Precautions

- The flow nozzle is not recommended for measurement of fluids with a large percentage of solids.

- Accuracy is dependent upon correct fabrication and installation of flow nozzle and associated piping.

- Flow calibration is recommended where high accuracy is required.

- Straightening vanes may be required upstream of the nozzle.

Flow Nozzle Installation

- The flow nozzle is usually installed in a section of pipe between flanges to permit insertion and removal. Gasket on the nozzle flanges are to be used in such a way that they do not extend into the pipe.

- The preferred installation position is horizontal. However, a vertical downflow position is preferred for wet steam or gases and liquids with suspended solids. A vertical upflow position is preferred for liquids with entrapped vapor.