HDPE Blending silo Load Sensor calibration procedure

- The silo which is going to be calibrate should be fully emptied.

- Check conditions before, around the load cells for related silo.

( Are they clean and the sensing surfaces of the load cells are touching to the silo.)

- Open the load cell front control panel near the silo. ( See figure-1)

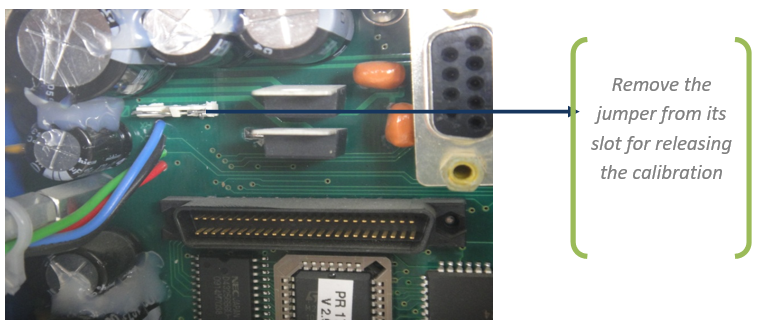

- Change the jumper position from close to open. ( Remove it)

( Releases the load cell transmitter for to calibrate. ( See figure-2)

After completing your calibration job put the jumper into original position.

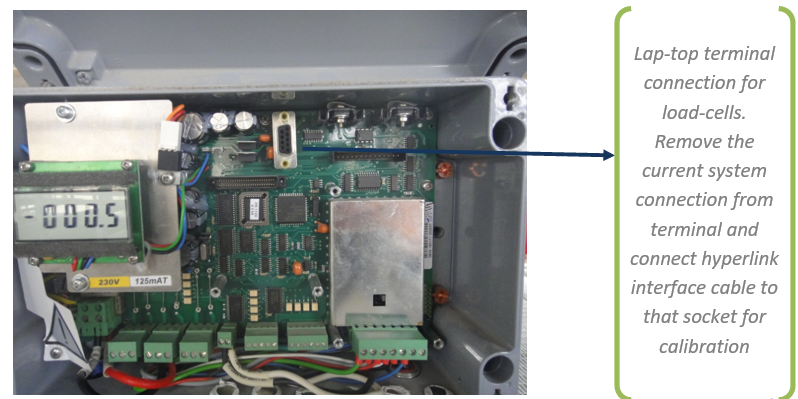

- Connect the lap-top to load cell transmitter terminal by interface cable.

( See figure-3 )

- Run hyper terminal software from the lap-top.

- After running the hyper terminal software insert necessary communication settings.

- In hyperlink software double click the phone icon and open the software.

(Software Items are coming sequentially)

- Enter to ‘’Configuration’’

- Set the analog output values in below before starting the calibration.

- Select ‘’Analog output ‘’

- Below gross zero = 4mA

- Above gross FSD = 20mA

- Value at 4 mA = 0.0 t

- Value at 20 mA = 500 t

- Go to ‘’Calibration’’

- Start-up ‘‘New calibration’’

- Enter ‘’ Full Scale’’

- Set the silo as full range for ‘’500.0 t’’

- Select ‘’ Step width to 5’’

- Set dead load ‘’ with current load’’

- Select ‘’Calculate span with load cell data’’

- Enter the ‘’Number of load cells in the system’’ ( # 4 for each blending silo )

- Enter ‘’Nominal Load data” as 125 t

- Enter ‘’ Gravity of location constant’’ as 7933

- Select ‘’Exit’’in

- Select ‘’ Accept data in calculate span’’

- Select ‘’ End Calibration ‘’

- Save and disconnect from the terminal.

- After finishing your job not to forget to put in jumper original position.

- Remove hyperlink interface cable from terminal and connect system cable to terminal.

- Close the panel door.

Like!! Thank you for publishing this awesome article.