What is Electrical Power Meter?

An electrical power meter, also known as an energy meter or watt-hour meter, is a device used to measure and quantify the amount of electrical energy consumed by an electrical load over a period of time. It provides information about the energy consumption of appliances, machines, buildings, and industrial processes. Here’s how an electrical power meter works:

Basic Components:

An electrical power meter typically consists of several key components:

- Current Sensor (Current Transformer): This device measures the current flowing through the electrical circuit.

- Voltage Sensor (Voltage Transformer): This device measures the voltage across the circuit.

- Measurement Circuit: Converts the current and voltage signals into corresponding electrical signals that can be processed.

- Processing Unit: Analyzes the electrical signals to calculate the power consumed by the load.

- Display: Shows the calculated energy consumption in units such as kilowatt-hours (kWh).

Working Principle:

The working principle of an electrical power meter involves measuring both the current and voltage of the circuit to calculate the power consumed.

- Current Measurement:

The current sensor (current transformer) is placed around one of the conductors carrying current to the load. It induces a proportional secondary current in its winding, which is proportional to the actual current flowing through the load. - Voltage Measurement:

The voltage sensor (voltage transformer) measures the voltage across the load. It reduces the voltage to a level suitable for measurement. - Power Calculation:

The measurement circuit takes the current and voltage signals and processes them to calculate the instantaneous power using the formula:

Instantaneous Power (P) = Current (I) × Voltage (V) - Energy Accumulation:

The instantaneous power is continuously calculated over small time intervals. The product of power and time gives the energy consumed during that interval. These energy values are summed up over time to calculate the total energy consumption. - Display and Readout:

The calculated energy consumption is displayed on the meter’s display in kilowatt-hours (kWh) or other appropriate units. Users can read and interpret this value to understand their energy consumption.

Modern power meters might offer additional features, such as communication interfaces (like Modbus or Ethernet) to connect to building management systems or for remote data collection.

Accuracy and Calibration:

Power meters are calibrated to ensure accuracy. The accuracy of a meter is usually expressed as a percentage of the reading. It’s important for accurate billing and monitoring of energy consumption.

In summary, electrical power meters measure the energy consumed by electrical loads by combining measurements of current and voltage, calculating the instantaneous power, and integrating the power over time to determine the energy consumption. These meters play a crucial role in managing energy usage and are commonly used in residential, commercial, and industrial settings.

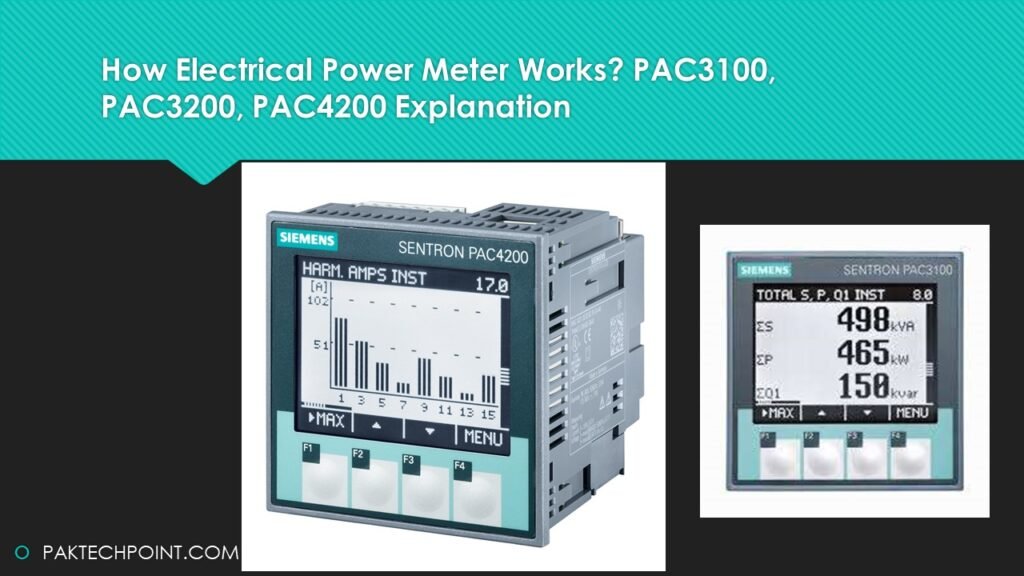

Use of Power Meter in Motor Control Center

It’s clear that tiastar motor control centers are versatile and integrated systems that can incorporate a wide range of devices to enhance their capabilities. One of the important types of devices that can be included in these motor control centers is power meters, which play a crucial role in monitoring and optimizing energy consumption. Siemens offers various power meter options, including the PAC3100, PAC3200, and PAC4200, each designed to meet different application needs. These power meters can provide real-time data on electrical parameters, contributing to efficient energy management strategies.

Power Meter Capabilities:

- Real-time Monitoring: Power meters allow for real-time monitoring of essential electrical parameters, including phase currents, phase and line voltages, power usage (kW), power factor, frequency, and peak demand.

- Energy Consumption Analysis: By measuring power usage over time, power meters facilitate the analysis of energy consumption patterns, aiding in identifying opportunities for energy savings and efficiency improvements.

- Power Quality Insights: Power meters, especially advanced models like the PAC4200, can provide insights into power quality issues such as harmonics, voltage fluctuations, and other anomalies that affect the stability of electrical systems.

- Integration with Motor Control Centers: Power meters can be seamlessly integrated into tiastar motor control centers, enhancing the center’s capabilities to monitor and manage energy usage effectively.

- Communication Options: Siemens’ power meters come with various communication options, such as Modbus, Profibus DP, PROFINET, and Ethernet, allowing these devices to communicate with other components within the motor control center and share data with external systems.

Siemens Power Meter Options:

- PAC3100: This power meter is designed for basic energy measurement applications. It offers essential energy consumption monitoring capabilities in a cost-effective package.

- PAC3200: Similar to the PAC3100, the PAC3200 provides more advanced measurement features, making it suitable for applications requiring greater accuracy and capabilities.

- PAC4200: The PAC4200 is a high-performance power meter offering comprehensive energy measurement and power quality analysis. It’s designed for more complex applications that demand in-depth insights into power parameters.

Incorporating power meters into tiastar motor control centers aligns with the growing importance of energy efficiency and power quality management in industrial and commercial environments. These devices contribute to more informed decision-making and effective energy optimization strategies.

What is PAC3200?

The PAC3200 is a versatile and advanced power monitoring and metering device developed by Siemens. It is part of the SENTRON portfolio, which includes a range of electrical solutions for power distribution, protection, and energy management. The PAC3200 is specifically designed to provide accurate measurement, monitoring, and analysis of electrical parameters in various industrial and commercial applications.

Key Features of PAC3200:

- Accurate Measurements: The PAC3200 is capable of measuring a wide range of electrical parameters, including voltage, current, power, energy, frequency, power factor, and more. Its high accuracy ensures reliable monitoring of energy consumption and power quality.

- Compact Design: Despite its advanced capabilities, the PAC3200 has a compact form factor that makes it suitable for installation in limited space environments.

- Multi-Function Display: The device features a clear, backlit LCD display that provides real-time data visualization, making it easy to monitor energy consumption and power parameters on-site.

- Data Logging: The PAC3200 is equipped with data logging capabilities, allowing it to store historical data that can be used for analysis, diagnostics, and performance evaluation.

- Communication Interfaces: It supports communication protocols such as Modbus RTU, Profibus DP, and Ethernet, enabling integration into various monitoring and control systems for remote data access and analysis.

- Energy Management: With its ability to measure and analyze energy consumption patterns, the PAC3200 helps users make informed decisions about energy efficiency and optimization.

- Load Profiling: The device can provide load profiling, which involves tracking how energy consumption varies over different time periods. This data can be invaluable for identifying peak consumption times and optimizing energy usage.

- Power Quality Analysis: The PAC3200 can detect power quality issues such as harmonics, voltage sags, swells, and other anomalies that can affect the stability and efficiency of electrical systems.

- Web Interface: Some versions of the PAC3200 come with a built-in web server, enabling users to access real-time data and perform configuration through a web browser, further enhancing remote monitoring and management capabilities.

In summary, the PAC3200 is a state-of-the-art power monitoring and metering device by Siemens, designed to provide accurate measurement and analysis of electrical parameters. Its compact design, advanced features, and communication capabilities make it an essential tool for energy management, power quality analysis, and overall efficiency improvement in industrial and commercial applications.

PAC3100 Power Meter by Siemens

The PAC3100 is another power monitoring and metering device from Siemens, similar to the PAC3200 but with a focus on essential energy measurement capabilities. It’s part of Siemens’ SENTRON portfolio and is designed to provide accurate measurements of key electrical parameters in a compact and cost-effective package. The PAC3100 is suitable for various applications where basic energy monitoring and measurement are required.

Key Features of PAC3100:

- Energy Measurement: The PAC3100 is primarily designed for energy measurement, including monitoring parameters such as voltage, current, active power, reactive power, apparent power, power factor, and energy consumption (kWh).

- Compact Design: Similar to the PAC3200, the PAC3100 also features a compact design, making it easy to install even in limited space environments.

- Easy-to-Read Display: It includes an LCD display that shows real-time data, allowing users to quickly view energy consumption and power parameters.

- Data Logging: The device can log historical data, providing insights into energy usage patterns over time.

- Communication Interfaces: It supports communication protocols like Modbus RTU, Profibus DP, and Ethernet, facilitating integration into various monitoring and control systems.

- Energy Management: The PAC3100 allows users to monitor energy consumption and gain insights into usage patterns, helping with energy efficiency efforts.

- Basic Power Quality Analysis: While its primary focus is on energy measurement, the PAC3100 may offer limited power quality analysis capabilities, such as detecting voltage fluctuations.

- Cost-Effective Solution: The PAC3100 is designed to provide essential energy measurement functionalities at a cost-effective price point, making it suitable for applications where advanced features are not required.

- Simple Installation and Configuration: With its user-friendly interface and straightforward setup process, the PAC3100 is easy to install and configure, allowing users to quickly start monitoring energy consumption.

In summary, the PAC3100 is a cost-effective energy monitoring and metering device from Siemens, intended for applications where basic energy measurement capabilities are needed. Its compact design, essential features, and communication capabilities make it a suitable choice for monitoring energy consumption and power parameters in various industrial and commercial contexts.

PAC4200 Power Meter by Siemens

The PAC4200 is a powerful and versatile power monitoring and metering device developed by Siemens. It belongs to the SENTRON portfolio and is designed to provide advanced energy measurement, monitoring, and analysis capabilities for a wide range of industrial and commercial applications. The PAC4200 offers comprehensive insights into energy consumption, power quality, and system performance.

Key Features of PAC4200:

- Energy Measurement: The PAC4200 is designed to accurately measure a wide range of electrical parameters, including voltage, current, power, energy consumption, power factor, and more.

- Power Quality Analysis: It offers in-depth power quality analysis, capable of detecting issues such as harmonics, voltage sags, swells, flicker, and other anomalies that can affect the stability and efficiency of electrical systems.

- Data Logging: The device can log historical data over time, allowing users to track energy consumption patterns and power quality trends.

- Communication Interfaces: It supports various communication protocols such as Modbus RTU, Profibus DP, PROFINET, and Ethernet, enabling seamless integration into diverse monitoring and control systems.

- Touchscreen Interface: The PAC4200 features a user-friendly touchscreen interface that provides real-time data visualization and access to configuration settings.

- Demand Management: It can monitor and manage energy demand, helping users optimize their energy usage during peak demand periods to reduce costs.

- Load Profiling: The device can profile energy consumption patterns over different time periods, aiding in understanding usage variations and planning energy management strategies.

- Web Server Capability: Some versions of the PAC4200 come with a built-in web server, allowing users to access real-time data and perform configurations remotely through a web browser.

- Diagnostics and Alarms: It offers diagnostic capabilities to identify potential issues, and alarms can be set to notify users when predefined thresholds are exceeded.

- Modular Design: The modular construction allows for flexibility in configuration, ensuring that the device can adapt to changing needs.

- Customization: The PAC4200 can be customized to suit specific applications and requirements.

- Multi-Function Capability: In addition to energy measurement, the PAC4200 can be used for load monitoring, process monitoring, and other advanced applications.

In summary, the PAC4200 is an advanced power monitoring and metering device by Siemens, designed to provide comprehensive insights into energy consumption, power quality, and system performance. Its capabilities make it an essential tool for optimizing energy usage, ensuring power quality, and improving overall efficiency in industrial and commercial environments.