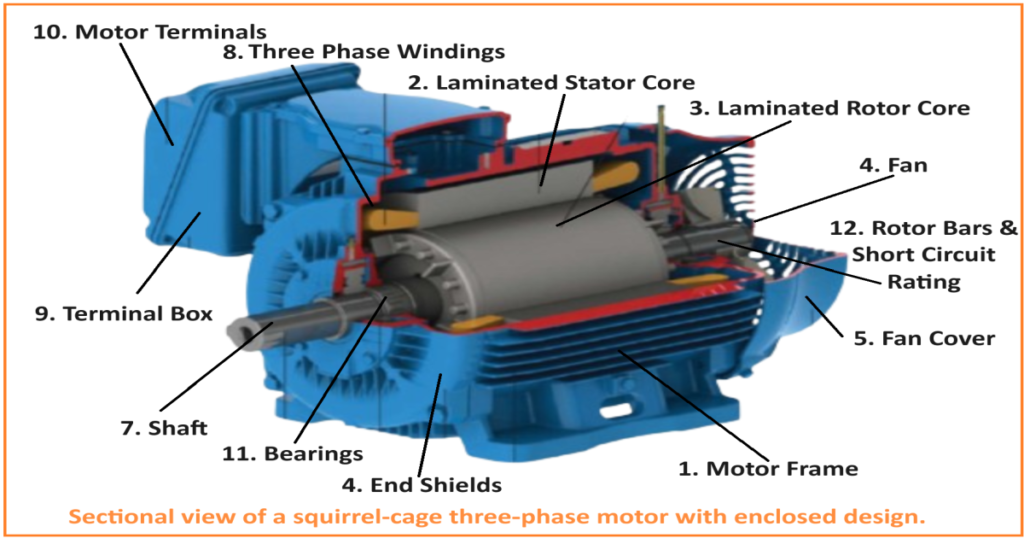

The three phase asynchronous motor, commonly referred to as the induction motor. It holds a prominent position in industrial applications due to its reliability, simplicity, and cost effectiveness. Its widespread use, particularly in the form of the squirrel-cage induction motor.

Working Principle.

The three-phase asynchronous motor works with a fixed stator and a rotating rotor. These parts don’t have direct electrical connections. Instead, the stator, with its coils, gets power from a three-phase supply network. This power creates a rotating magnetic field that interacts with the rotor across an air gap. Both the stator and rotor are made of special plates that minimize energy losses.

When the stator coil is connected to the power supply, it initially creates a magnetic field that starts rotating at a specific speed called the synchronous speed. This speed is determined by the frequency of the power supply and the number of pole pairs in the motor.

ns = 60 · f/p

ns = synchronous speed in min

f = frequency in s

p = pole pair number (pole number/2)

For example, with a 50 Hz supply and two poles, the synchronous speed is 3000 revolutions per minute (rpm). You can find the synchronous speeds for different pole numbers and frequencies in a table.

The rotating magnetic field from the stator induces a voltage in the rotor coil, which creates a current in the rotor. This current interacts with the stator’s rotating field, producing a torque that drives the rotor. However, the rotor’s speed is always slightly slower than the synchronous speed of the stator’s field (coil).

s = (ns-n)/ns.

s = slip.

ns = synchronous speed.

n = operational speed.

This speed difference, called slip, is essential for inducing voltage and current in the rotor, which are needed to generate torque. The slip increases with the load on the motor and depends on factors like rotor resistance, which also affect the motor’s energy efficiency.

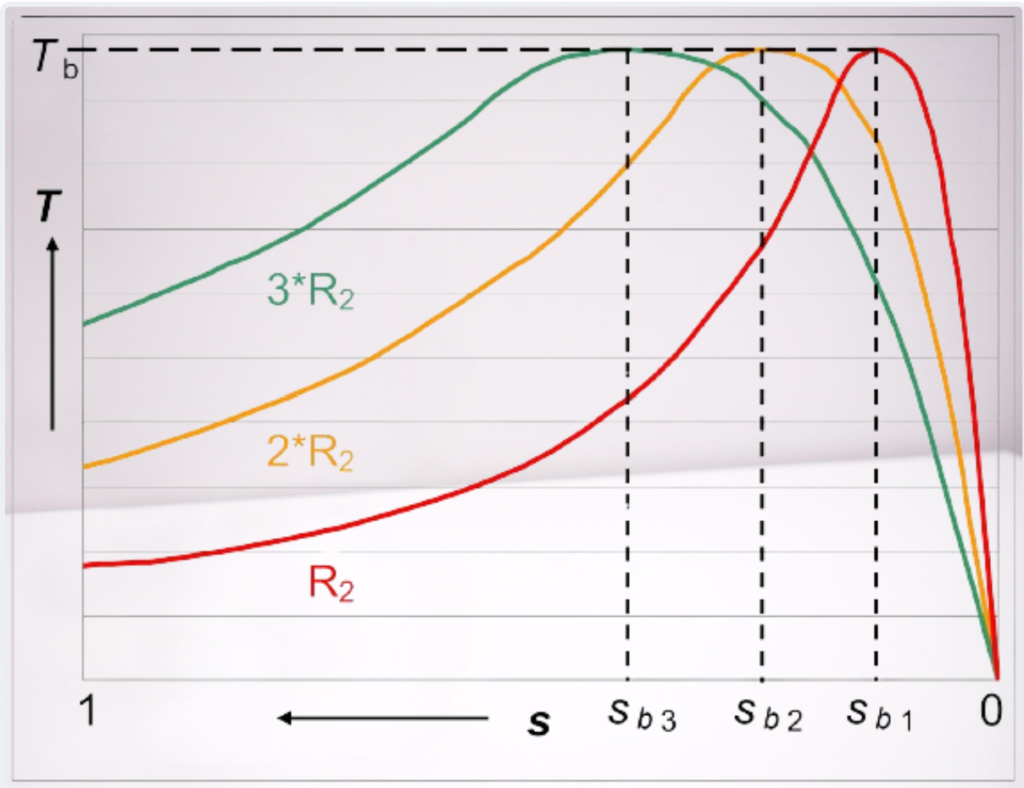

The torque curve of an asynchronous motor (induction) motor shows a maximum torque called the breakdown torque. This torque increases as speed increases until it reaches a maximum, after which it drops rapidly to zero at the synchronous speed.

If the mechanical load exceeds the breakdown torque, the motor stalls and stops. The magnitude of the breakdown torque depends on the motor’s electrical characteristics, particularly its reactance, which is determined by its design. In slip-ring motors, the slip at breakdown torque can be adjusted by adding external resistors to the rotor circuit.

By adding resistors to the rotor circuit of asynchronous motors, the torque characteristic can be somewhat extended.

Tb = Breakdown torque.

s = Slip.

sb = Breakdown slip.

R2 = Rotor resistance.

Breakdown torque (Tb) and breakdown slip (sb) are key factors in this extension. The breakdown torque represents the maximum torque the motor can deliver before stalling, while the breakdown slip is the slip value corresponding to this maximum torque. The rotor resistance (R2) plays a significant role in determining these values. By adjusting the rotor resistance, either through external resistors or by design, the breakdown torque and slip can be controlled to some extent, influencing the motor’s torque output over a wider range of operating conditions.

Difference between an asynchronous and a synchronous motor.

Here’s a comparison table outlining the differences between asynchronous (induction) and synchronous motors:

| Feature | Asynchronous (Induction) Motor | Synchronous Motor |

|---|---|---|

| Operation. | Rotates at slightly lower speed than the rotating magnetic field. | Rotates at the same speed as the rotating magnetic field. |

| Speed Control. | Speed is not precisely controlled and varies with load. | Speed remains constant regardless of the load. |

| Synchronization. | Does not require external synchronization. | Requires external synchronization with an excitation source. |

| Applications. | Widely used in various applications including industrial machinery, pumps, fans, compressors, and household appliances. | Used in applications where precise speed control is required, such as synchronous clocks, industrial machines, and power factor correction systems. |

| Complexity. | Relatively simpler construction and operation. | May have more complex construction and require additional components for synchronization. |

| Cost. | Generally lower cost. | Can be higher cost due to additional components and precision required. |

| Efficiency. | Slightly lower efficiency compared to synchronous motors. | Generally higher efficiency due to constant speed operation. |