This article is about Hydrostatic Test Procedure of Pipeline, Pressure Vessel, Storage Tanks as per International Standard and Codes (ASME) and what are testing requirements and what problems can face during testing. You can extract this article as PDF. You will understand here about hydrostatic test pressure calculation.

Hydrostatic Test Procedure and Lay-up Procedures

1.1 Purpose

The purpose of this testing procedure is to provide guidelines to conduct Lay-up of equipment according with SAES-A-007 (Hydrostatic Testing Fluids and Lay-up Procedures) in Plants and Refinery Projects. This document is issued for purpose of the special process work procedure of “SCHEDULE “Q”.

Why We Do Hydrostatic Test for Equipment and Pipeline?

1) This standard establishes requirements to control corrosion and microbiological damage after hydrotesting of new, revalidated, and refurbished equipment when equipment is hydrotested in accordance with SAES-A-004, SAES-L-150 or required by other standards that specially reference SAES-A-007.

2) The procedures in this standard are designed to prevent corrosion due to oxygen (air) ingress and to prevent microbial induced corrosion. Lay-Up procedure shall prevent oxygen ingress except as specially allowed in this procedure.

3) Lay-up Matrix for specific systems is presented in Attachment 1 of this procedure. If there is any apparent conflict between Attachment 1 and the general requirements in the remainder of the procedure, Matrix in Attachment 1 shall govern.

4) No deviation shall be made from this procedure without written approval from COMPANY. However, Company and Contractor can mutually agree to change the lay-up method, if site condition required modification.

REFERENCE DOCUMENTS

| Project Specifications |

| Piping Material Specification |

| Line Designation Table for J10 |

| Procedure for Piping Pressure Test |

2.2 Saudi Aramco Standard

SAEP-327 Disposal of wastewater form cleaning, flushing and dewatering pipelines and vessels.

SAES-A-004 General Requirements for Pressure Testing.

SAES-A-007 Hydrostatic Testing Fluids and Lay-Up Procedures.

SAES-L-350 Construction of Plant Piping.

SAIC-A-2018 SA Check List – Test Medium for Hydrostatic Testing & Lay-up

SATR-A-2009 SA Test Report – System Lay-up Report (Certificate)

SATR-A-2014 SA Test Report – Water Chemistry Report

SATIP-A-004-001 Pneumatic Pressure Testing.

SATIP-A-004-002 Hydrostatic Testing of on Plot Piping.

G.1.2.012 Isolation Lock out and Use of Hold Tag

G.1.2.102 Pressure Testing Safety

G.1.2 . 710 Mechanical Completion and Performance Acceptance of Facilities

3. RESPONSIBILITIES

3.1 Site Manager

Site Manager shall responsible for overall management and HSE of all Construction and Pre commissioning activities at site including fabrication, installation and testing.

3.2 Pre-commissioning Manager

- Responsible for the overall implementation of the work procedure, coordination with parties involved in the lay-up activities. The Pre-commissioning Manager will ensure that specified preparatory works and associated documentation are prepared in accordance with this procedure.

- As for Lay-up after Pressure Test, Piping manager will handle it as construction activity.

3.3 QC Manager

Ensure the adequate implementation and application of this procedure according to SAUDI ARAMCO Standards and Specifications, Applicable Codes and Manufacturer Recommendations.

3.4 QC Inspector

- Responsible for witnessing/approval of the activity, to ensure that the in-situ Layup of piping/equipment is performed and developed in an orderly controlled manner in compliance with the Saudi Aramco Standards, Project Specifications and applicable SATIP/SAIC inspection and test plan.

- QC Inspector shall be responsible to coordinate the communication way for the lay-up activities between CONTRACTOR and COMPANY (PIO and SAPMT) by issuing RFI.

- QC Inspector will be responsible for monitoring the compliance of the lay-up

3.5 Pre-commissioning Supervisor

- The Pre-commissioning Supervisor shall be responsible for executing the work in strict compliance of this procedure, following and controlling the safety procedure during the lay-up activities. Secure all necessary work permits prior to carry out the activity.

- The Pre-commissioning Supervisor shall be responsible for ensuring that System Lay-up is maintained.

- As for Lay-up after Pressure Test, Piping supervisor will handle it as construction activity.

4. SAFETY CONSIDERATION DURING HYDROSTATIC TEST

5. LAY-UP METHOD

Equipment shall be laid-up after hydrostatic test, unless it can be ensured that it will be returned to service within 30 days from the first introduction of hydrostatic test water to the system. Use one of the lay-up methods detailed below.

- These methods shall be applied for piping and equipment which are made of Carbon Steel, Galvanized Carbon Steel, Low Alloy Steel, and Stainless Steel, as per SAES-A-007.

- At the end of the lay-up, commission and start up heat exchangers within 14 days, and other equipment within 60 days.

5.1 No Lay-up

- According to SAES-A-007 Para 7.7, water shall not require treatment if used to pressure test completely internally coated or lined equipment, or systems entirely fabricated with non metallic materials. No lay-up procedure is required for totally non-metallic systems (e.g., PVC or RTR pipe).

- Regardless of piping material, “No Lay-up” will be applied to all piping which is open to the atmosphere such as trim vents and drains, which are categorized as visual, gravity and service test package.

5.2 Ambient Lay-up

- Ambient lay-up will be used on services where all of the following conditions apply:

- Drains are available at all low points to ensure complete removal of water

- Corrosion allowance has been provided,

- Pitting can be tolerated; and

- Particulate rust can be tolerated.

- Water from the system will be removed. For facilities other than pipelines, drain the system completely, sweep and mop as required to ensure that no visible traces of water remain.

- Dewatering condition shall be confirmed with monitoring no more water coming out from the test package for a minimum ten (10) minutes.

- After confirming that the test package is drained, , the system will be protected to prevent the entry of sand or rainwater. Holding positive pressure will not be required for Ambient Lay-up.

5.3 Dry Lay-up

- Dry lay-up using dew point controlled air may be performed in systems where the dew point can be successfully reached within 1 week. Longer drying periods using air may contribute to the generation of excessive quantities of corrosion products in lines. Therefore, dry lay-up using air is only appropriate for systems that can be easily dried. One means to assure effective drying within the required time is to limit the length of the system being hydrotested at one time.

- After hydrotest, water from the system shall be removed. For facilities other than pipelines, the system will be completely drained, sweep and mop as required to ensure that no visible traces of water remain, when applicable.

- Immediately after dewatering, the system will be dried until ensure a dew point of -1C or less at all exit points. Drying operation will be done by blowing dry air through the system for not less than 12 hours to allow any remaining moisture to come to equilibrium with the dry air.

- After drying operation it will be checked and ensured that all measurement locations are at or below the required dew point. In case that a measured dew point at any one location is above the set limit drying procedure will be repeated.

- Dew point temperature readings at each test location and the pressure of the line or system at the time of dew point measurement will be recorded. If different to the actual system or line pressure, the pressure at which the dew point measurement is made will be recorded.

- When the required dew point is reached (lower than -1°C), the system will be pressurized with dry air to the final lay-up pressure (30 psig) and hold pressure during bubble test to be done to ensure no leak in the piping system.

- The system will be shut in, maintaining and monitoring the pressure during the lay-up period.

- Some equipment, such as soft seated valves and control valves will be removed from the line, prior to hydrotest, as per SAES-A-004 Para. 8. However, remaining equipment must be carefully dewatered. As the final stage of the dewatering process, remove water from pipeline valves and all other valves that may be damaged by trapped hydrotest water by blowing through the top drain and displacing fluid out of the bottom of the valve.

5.4 Inert Gas (Nitrogen) Lay up

The way will consist in displacing the hydrostatic test water by positive pressure with nitrogen or sweet gas until no water drains out of the system. Shut in the system under positive pressure until commissioning and start-up.

| Oil Lay–up |

| Lube oil lines are tested by lube oil as per SAES-A-004 and SAES-L-150. Therefore, after testing and cleaning, system will be left with oil until Commissioning stage, when the oil will be replaced by new brand one. |

| Special Requirement |

1) Utility Systems

- Utility and potable water systems shall be tested in accordance with SAES-S-060 or SAES-S-070, as appropriate.

- Potable water systems shall be tested with fresh potable water only following the requirements of SAES-S-070, Paragraph 18 . 2 . Oxygen scavengers and biocides shall not be used in potable systems.

2) Dry Gas and Refined Hydrocarbon Product Pipelines and Piping

- Prevent corrosion during hydrotest and lay-up procedures for sweet sales gas, ethane, refined products such as gasoline, kerosene, diesel, etcetera, and processed Corrosion products and other contaminants introduced during construction, hydrotesting, and start-up can create major problems for many years.

- When water is finally removed from the pipe, either ai the end of the hyrotest or at the end of a wet lay-up, the system shall be thoroughly dried. Air drying shall not be used for pipelines. Air drying may be used for small in-plant piping systems if drying can be completed in no more than one wee

3) Plant Piping

- In general, new or existing pipework in plants and refineries will be hydrotested either on site or in a plant fabrication shop. Due to the shorter physical length of this equipment, hydrotest can be effected in a shorter time than that which would require chemical treatment with oxygen scavengers or biocides per SAES-A-007 5.1, 6.3, or 5.2.2. Therefore, unless these time limits are exceeded, no chemical treatment is required.

- Due to the complexity of plant construction operations, often new plant pipework is laid up by drying following the requirements of SAES-A-007 Para. 5.2.3 to achieve a dew point of -1C . Drying is normally achieved within a plant using dry air or sometimes nitrogen.

- Chloride limits for 3xx-series stainless steels must be strictly followed.

- Water shall not require treatment if used to pressure test completely internally coated or lined equipment, or systems entirely fabricated with non-metallic materials. No lay-up procedure is required for totally non-metallic systems (e.g., PVC pipe).

- Lube oil systems shall be pressure tested following the requirements of SAES-L-150. Water shall not be used.

- Instrument air systems shall be pressure tested following the requirements of SAES-J-901 and SAES-L-150. Water shall not be used.

- Boilers shall be laid up per SAEP-1026.

- For heat exchangers, lay-up shall be required unless start up occurs within 14 days of commencing the hydrostatic test.

4) Stainless Steel Equipment

- Type 300-series stainless steels shall be tested only with water that has very low chloride content in order to avoid pitting and stress corrosion cracking. The maximum allowable chloride concentration is 50 ppm. Verify the quality of the water following the requirements of SAES-A-007 Para. 4.2.

- Type-400-series stainless steels are highly prone to atmospheric corrosion. Type 400 series stainless steel trimmed stainless steel (SS) valves shall be removed from pipelines before hydrotest. If it impossible to remove such SS valves from the line, then written hydrotest procedures must be prepared and approved ahead of time allowing the SS valves to remain in place. When stainless steel equipment containing any Type-400 series stainless steels is left in place, it shall be hydrotested in accordance with the requirements of SAES-A-007 Para. 6.3, 6.4, and 6.5. The hydrotest procedure shall carefully detail measures prevent corrosion including lay-up of the equipment. Do not use ambient lay-up for equipment made of 400-series stainless steels.

6. IMPLEMENTATION

6.1 Water Quality

- Water used for any part of the hydrotesting or subsequent lay-up shall have a sulphate reducing bacteria (SRB) count of 10³ per ml or less as determined by the RapidChek II Method or alternative test method approved by Supervisor, CTU/ME&CCD/CSD. Water that has a higher bacteria count may be accepted at the discretion of the Concerned authority, after treatment with biocide and retesting. Measurement of SRB shall be carried out as close as to the introduction of the water to the system.

- It will be ensured that the mixing of the waters will not cause scaling if water used for Hydrotest or subsequent lay-up is coming from more than one source.

- Water used for any part of the hydrotesting or subsequent lay-up shall be clean and free from suspended matter. Suspended matter in the water shall be extracted, before use, by a filter capable of removing 99% of all particles 53m (2.1 mil) in diameter and larger, or equivalent to using a 270 mesh wire mesh screen.

- See Section 5.7.4}, paragraph “a” for restrictions on the quality of water used for testing/lay-up austenitic stainless steels. Seawater or high TDS aquifer water shall not be used for this purpose. The construction contractor shall keep a permanent written record of the water supplied for testing stainless steels including a record of tests performed on the water.

- Potable water systems shall be tested with fresh potable water only following the requirements of SAES-S-070, Paragraph 18.2. Oxygen scavengers and biocides shall not be used in potable systems.

- An approved oxygen scavenger (see Appendix 1) shall be added to the hydrostatic test water, when the equipment contact time with hydrotest water may exceed 14 days for carbon steel and low alloy steel equipment or 4 days for stainless steel equipment. Treat the water before it enters the system.

6.2 Precaution

Special attention shall be paid to the following precautions when lay-up is performed:

- A maximum allowable chloride concentration shall be less than 50 ppm for austenitic stainless steel pipes and piping components in contact with water to avoid stress corrosion crack. After all the operations, the piping systems will be completely drained, dried up to having a dew point below -1 °C and protected against corrosion as per Section 5.7.4).

- After hydrotest, lines will be carefully drained and air blown using plant air by connecting hoses to suitable points, as required. After the air blow to a required dryness, Lay-up procedure will be applied.

- Suitable measures will be taken to ensure that during drainage water does not affect/enter to the equipment. Special attention will be paid to equipment protection and protection measures such as installation of temporary elbows or hoses at water outlet points, plastic covers on equipment and nozzles shall be used when required.

- Systems laid-up with nitrogen (Inert gas lay-up) will be properly identified and tagged.

- Access to areas where nitrogen purge is being carried out will be restricted.

- When working in open areas, close to nitrogen outlet, it is mandatory to monitor oxygen levels during the work. Check proper functioning of Oxygen detector.

6.3 Planning

- Selected Lay-up method shall be indicated in each test package as per stated in Lay-up Method Matrix (Attachment 1 ).

- Before starting any hydrotest, lay-up method to be applied shall be approved and all required material for its execution available.

- When possible the re-instatement of the system should be done before the execution of lay-up activity. However, total duration between first introduction of water and execution of lay-up will not exceed of 30 days for Carbon steel or 14 days in case of stainless steel.

- Check/confirm the following items:

- Confirm that handheld oxygen meter or dew point meter is on place as per needs according to the Lay-up method.

- COMPANY personnel, who will witness the activity, shall be informed 24 hours prior to start up of Lay-up activities by issuing a RFI.

- Confirm that the normal operation pressure of the system allows to keep the final positive pressure specified during dry and inert gas lay-up (30 psig). If normal operation pressure is lower than positive pressure for lay-up, new value shall be submitted to the COMPANY for their approval.

- A Cold Work Permit will be issued for lay-up operation according to CONTRACTOR procedures.

6.4 Site Preparation

- Components in new piping systems which interfere with filling, venting, or draining shall not be reinstalled until lay-up is completed or just before pressurizing the system up to the final positive pressure. These include orifice plates, flow nozzles, sight glasses, positive displacement and turbine meters and other in-line equipment.

- During draining operations, the following actions will be taken when necessary:

✓ Protections/covers will be used to protect exposed motors, insulation, and instruments near the flow outlet.

✓ To direct the outlet flow towards a place where there is no sensitive equipment.

✓ To change the direction of the flow by rotating an elbow.

✓ To connect a hose pipe at the outlet to drive the flow to a safe location.

✓ To add a dummy spool to extend the outlet further.

✓ On platforms, to protect the equipment and the people on the deck underneath.

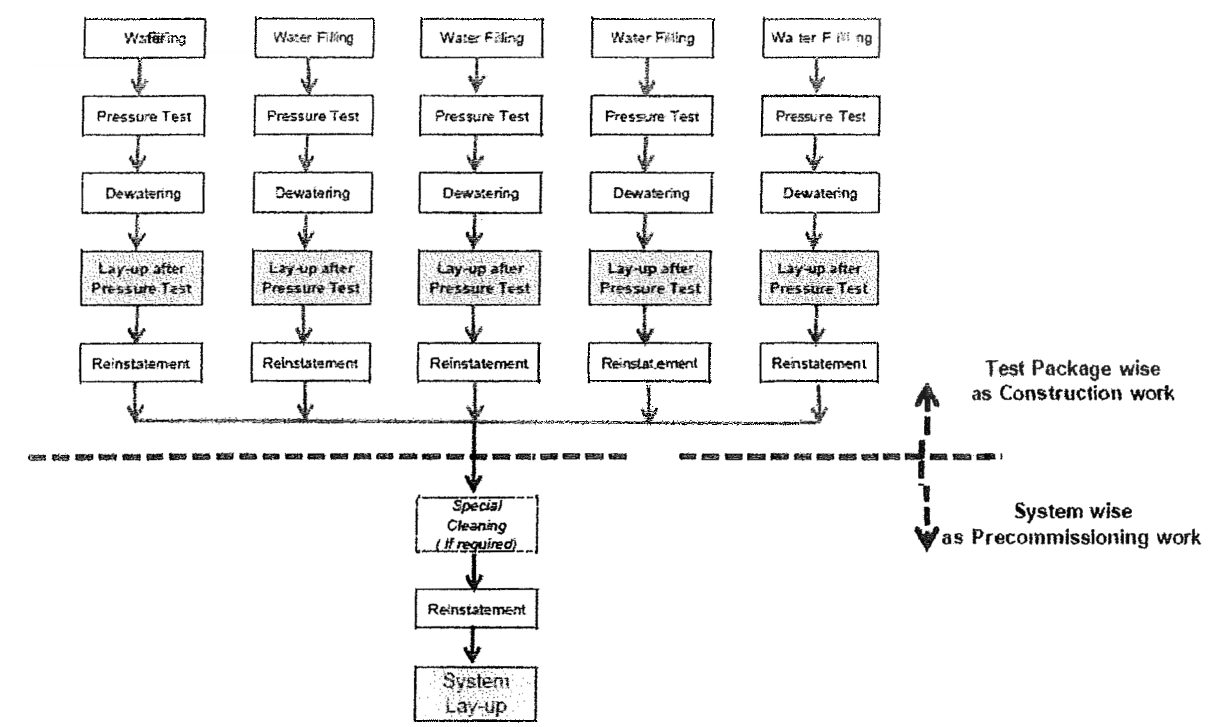

6.5 Work Flow

- First lay-up will be conducted by the test package wise as the construction work after the pressure test and reinstatement.

- System lay-up will be conducted as the pre-commissioning work, once all related works are completed.

Table 1 – Lay-up Work Flow

6.6 Post Work

- Suitable protective measures shall be taken for pipes where ambient lay-up is applied, to ensure ingress of dirt does not occur.

- For dry lay-up after System Lay-up, re-measure the dew point at all original test locations after reaching final lay-up pressure. Check the dew point and pressure later than 12 hours after lay-up. If dew point is not higher than -1 °C at lay-up pressure, check the dew point and pressure after 1 week. After 1 week, it still remain below than -1C at lay-up pressure, check the dew point by monthly after. (If any dew point reading is found to be higher than -1 °C at the lay-up pressure, then the entire line must be dried again.)

- For dry lay-up after System Lay-up, positive pressure of 30 psi g is to be maintained and monitored throughout the duration of pre-commissioning, unless the lay-up pressure is no higher than Maximum Allowance Operating Pressure (MAOP).

- After lay-up is executed, the corresponding record sheet shall be signed off by all parties confirming the acceptance of the work. This record will be included in the corresponding Test Package:

✓ System Lay-up Report (SATR-A-2009)

✓ Water Chemistry Report (SATR-A-2014). If required.