This article is about Incandescent Light Fixtures Material Selection & Technical Specification for commercial buildings, plants and refinery projects as per international codes and standards.

Incandescent Light Fixtures Material Selection & Technical Specification

General Requirements

| Identification procedures shall be implemented for all materials, parts and components, including partially fabricated assemblies. Identification of an item shall be done by using tags, stamps, color coding, stencils or labels. The location and method of identification shall not affect the function or quality of the material. |

| Traceability shall be maintained on the equipment. Documents and records shall enable the equipment to be traced throughout delivery, storage, fabrication, erection, installation, repair, modification and use. |

| QC Before Installation- Equipment shall conform to all applicable requirements, standards, and specifications prior to release to be used as part of work. |

| Verify that equipment assembly parts and components shall be free of damage. |

| Verify the equipment assembly parts shall be new and unused. |

| Contractor shall implement procedures for handling, storage, and preservation of materials as specified in all applicable specifications, manufacturer recommendations and company’s standards. |

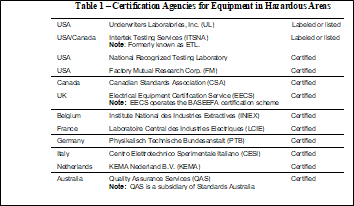

| Lighting fixtures shall be third-party labeled & listed as meeting the requirements of the Underwriters Laboratories UL (UL 1570, UL 935 if approved or applicable ), Factory Mutual or the Canadian Standards Association. |

| Other labels or listings shall originate from an independent third party laboratory and shall state either that the fixtures meet appropriate designated standards or have been tested and found suitable for use in a specified manner. Lighting fixtures for hazardous areas shall meet certification requirements of SAES-P-100. |

| All luminaires (fixtures) shall be marked with the maximum lamp wattage or electrical rating, manufacturer’s name, trademark, or other suitable means of identification. NFPA 70, Sec. 410.35 (a) |

| Light fixtures shall be suitable for the environment where they are installed. |

| Wiring compartments, including their entrances, shall be such that conductors may be drawn in and withdrawn without physical damage. NFPA 70, Sec. 410.36 |

| Luminaires (fixtures) shall be wired with conductors having insulation suitable for the environmental conditions, current, voltage, and temperature to which the conductors will be subjected. NFPA 70, Sec. 410.24 |

Specific Requirements for Lighting Fixtures in Hazardous Location

| Each luminaire (lighting fixture) shall be identified as a complete assembly for the Class I, Division 1 location and shall be clearly marked to indicate the maximum wattage of lamps for which it is identified. NFPA 70, Sec. 501.9 a (1) |

| Each luminaire (fixture) shall be identified for Class II locations and shall be clearly marked to indicate the maximum wattage of the lamp for which it is designed. In locations where dust from magnesium, aluminum, aluminum bronze powders, or other metals of similarly hazardous characteristics may be present, luminaires (fixtures) for fixed or portable lighting and all auxiliary equipment shall be identified for the specific location. NFPA 70, Sec. 502.11 a (1) |

| To determine suitability of lighting fixtures for use in hazardous areas where the maximum daily ambient temperature exceeds 40°C, the temperature code (T-rating) shall be based on an ambient test temperature of 50°C or higher. |

| A spacing of not less than 3/64 inch (1.2 mm) shall be maintained between live parts and a metal enclosure. UL- 542, Sec. 9.1 |

Each wired fixture section shall be plainly marked with the manufacturer’s name, trademark, or similar means of identification. UL 1572, Sec. 58.2.2

The labeling, listing, or certification of Lighting Fixture required to be approved for use in hazardous locations shall be based on the latest version of the following standards or procedures:

a) UL standards (for approved enclosures and fittings: UL 886), or

b) FM procedures or

c) CSA standards, or

d) IEC standards, or

e) ISA standards

SAES-P-100, Sec. 5.3.4

| A fixture that is intended for use in damp locations shall be marked ”Suitable for damp locations.” UL 1572, Sec. 1.3 |

| Luminaires (fixtures) installed in corrosive locations shall be of a type suitable for such locations. NFPA 70, Sec. 410.4 b |

| Lighting Fixtures for Hazardous Areas-Hazardous area classification shall be in accordance with the requirements of SAES-B-068. SAES-P-100, Sec. 5.3.1 |

| A fixture that does not comply with the requirements for damp or wet locations shall be marked “Suitable for dry locations only.” UL 1572, Sec. 35.3 |

| A fixture provided with lamp holders for both incandescent and fluorescent lamps (a combination incandescent fluorescent lamp fixture) shall comply with the Standard for Fluorescent Lighting Fixtures, UL 1570, and with the requirements in this standard insofar as they apply to construction, test methods, and marking requirements unique to incandescent lamps. UL-1571, Sec. 1.3 |

| A fixture provided with lamp holders for both incandescent and high intensity discharge lamps (a combination incandescent high intensity discharge lamp fixture) shall comply with the Standard for High Intensity Discharge Lighting Fixtures, UL 1572, and with the requirements of this standard insofar as they apply to construction, test methods, and marking requirements unique to incandescent lamps. UL-1571, Sec. 1.4 |

| An incandescent lamp for general use on lighting branch circuits shall not be equipped with a mogul base if rated over 1500 watts. NFPA 70, Sec. 410-65 c |

| An incandescent lamp for general use on lighting branch circuits shall not be equipped with a medium base if rated over 300 watts. NFPA 70, Sec. 410-53 |

| Recessed Incandescent Luminaires (Fixtures). Incandescent luminaires (fixtures) shall have thermal protection and shall be identified as thermally protected. NFPA 70, Sec. 410-53 |

| Recessed incandescent luminaires without thermal protection are not permitted unless they are listed and identified as providing equivalent temperature protection by construction design. NFPA 70, Sec. 410-65 c |

| Incandescent lamp luminaires (fixtures) shall be marked to indicate the maximum allowable wattage of lamps. NFPA 70, Sec. 410-70 c |

| Direct-control switches and switching contacts used on incandescent lighting circuits shall have a continuous current rating of at least 1.5 times the steady-state current of the lighting load. |

| Incandescent spot fixtures with dimmers to provide variable illumination of up to 1,000 lux shall be used for supplementary task lighting in work areas within the control room as required. |

International Codes & Standards

| 3. NFPA 70 — National Electrical Code (NEC), 2008 Edition |

| 4. UL-1571 Incandescent Lighting Fixtures, APRIL 30,1996 |

| 5. UL 1572, UL Standard for Safety for High Intensity Discharge Lighting Fixtures, Fourth Edition, Dated July 27, 1995 |

| 6. UL 542 UL Standard for Safety for Lamp holders, Starters, and Starter Holders for Fluorescent Lamps, November 29, 1999 |

| 5. SAES-P-123 – Lighting, 29 July 2006 |

| 6. SAES-P-100 – Basic Power System Design Criteria, 25 June 2007 |