Why its Necessary to discuss Joint Sealant Materials and its types?

a. Movement of the structure resulting in stresses on the sealant exceeding sealant manufacturer’s written specifications for sealant elongation and compression caused by structural settlement or errors attributable to design or construction.

b. Disintegration of joint substrates from natural causes exceeding design specifications.

c. Mechanical damage caused by individuals, tools, or other outside agents.

d. Changes in sealant appearance caused by accumulation of dirt or other atmospheric contaminants.

Joint Sealant Materials

Joint sealants, backings, and other related materials shall be compatible with one another and with joint substrates under conditions of service and application, as demonstrated by sealant manufacturer based on testing and field experience.

Colors of exposed joint sealants shall be as selected by Company from manufacturer’s standard colors. For concealed materials, natural colors that have best overall performance shall be provided.

Joint Sealant Types

Elastomeric Joint Sealants

-

- Elastomeric sealants shall comply with ASTM C 920 and other requirements indicated for each liquid-applied chemically curing sealant in 5.7 including those referencing ASTM C 920 classifications for type, grade, class, and uses.

- Where additional movement capability is specified in 5.7, products tested for adhesion and cohesion under maximum cyclic movement in accordance with ASTM C 719 shall be able to withstand the specified percentage change in the joint width existing at the time of installation, and remain in compliance with other requirements of ASTM C 920 for uses indicated.

- Where elastomeric sealants are specified in 5.7 to be nonstaining to porous substrates, products shall be provided that have been tested in accordance with ASTM C 1248 and have not stained porous joint substrates proposed for project.

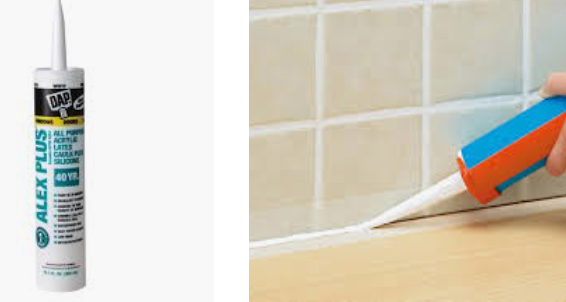

Latex Joint Sealants

Latex sealants shall comply with ASTM C 834 for product indicated in 5.8.

Acoustical Joint Sealants

Acoustical sealant for exposed and concealed joints specified in 5.9 shall be manufacturer’s standard nonsag, paintable, nonstaining latex sealant complying with ASTM C 834. Acoustical sealant shall effectively reduce airborne sound transmission through perimeter joints and openings in building construction, as demonstrated by testing representative assemblies in accordance with ASTM E 90.

Joint-sealant Backing

Sealant backings shall be of materials and types that are nonstaining; compatible with joint substrates, sealants, primers, and other joint fillers; and are approved for applications indicated by sealant manufacturer, based on field experience and laboratory testing.

Elastomeric tubing sealant backings shall be neoprene, butyl, EPDM or silicone tubing, complying with ASTM D 1056, nonabsorbent to water and gas, and capable of remaining resilient at temperatures down to -32° C. Products shall have a low compression set, and shall be of a size and shape to provide a secondary seal, to control sealant depth, and otherwise contribute to optimum sealant performance.

Bond-breaker tape shall be polyethylene or other plastic recommended by sealant manufacturer. Tape shall prevent sealant from adhering to rigid, inflexible joint-iller materials or joint surfaces at back of joint, where such adhesion would result in sealant failure. Self-adhesive tape shall be used where applicable.

Miscellaneous Materials used in Joint Sealants

Primer: Material recommended by joint sealant manufacturer shall be provided where required for adhesion of sealant to joint substrates indicated, as determined from preconstruction joint-sealant-substrate tests and field tests.

Chemical cleaners for nonporous surfaces shall be acceptable to manufacturers of sealants and sealant backing materials. They shall be free of oily residues or other substances capable of staining or harming joint substrates and adjacent nonporous surfaces in any way, and formulated to promote optimum adhesion of sealants with joint substrates.

Masking tape shall be nonstaining, nonabsorbent material, compatible with joint sealants and surfaces adjacent to joints.