This article provides general information and selection guidance on level-measurement devices used in process plants.

Level measurement is a critical aspect of various industrial processes and applications. It involves determining the level of liquids, solids, or slurries within containers or vessels. Accurate level measurement is essential for process control, inventory management, and ensuring the safety and efficiency of operations.

Level transmitters play a crucial role in this process, providing real-time data about the level of the substance being measured. These devices utilize different working principles to detect and transmit level information to control systems or display panels.

In this article, we will explore the different types of level measurement techniques commonly used in industrial settings. We will delve into the working principles of level transmitters, ranging from simple float switches to sophisticated ultrasonic and radar-based sensors. Understanding the diverse range of level measurement methods will enable us to select the most suitable solution for specific applications, ensuring optimal performance and reliability in various industrial processes. Let’s explore the fascinating world of level measurement and the technology behind level transmitters.

What is Level Measurement?

Level measurement is the process of determining and quantifying the height or level of a substance within a container, vessel, or tank. It is a crucial aspect of various industrial processes and applications where the accurate measurement of liquid, solid, or slurry levels is essential for process control, inventory management, and safety.

It is used in a wide range of industries, including chemical, pharmaceutical, oil and gas, water and wastewater, food and beverage, and many others. The goal of level measurement is to obtain real-time data on the quantity of material present, ensuring that processes are efficiently managed and maintained within desired operating parameters.

Level Measurement Methods

Level measurement methods provide a diverse range of techniques to meet specific application requirements across various industries. Each method utilizes unique principles to accurately measure the level of substances in containers or vessels. The available options for level measurement include:

- Capacitive: Utilizes changes in capacitance caused by the presence of the substance to measure the level.

- Hydrostatic: Determines the level by measuring the hydrostatic pressure at the bottom of the container.

- Ultrasonic: Uses ultrasonic waves to measure the time taken for their reflection to determine the level.

- Conductive: Measures the electrical conductivity of the substance to determine its level.

- Electromechanical: Employs mechanical mechanisms, such as floats or displacers, to indicate the level of the substance.

- Float Switch: Uses a float that rises or falls with the substance’s level to trigger switch contacts and indicate the level.

- Free Space Radar: Utilizes radar waves transmitted through the free space to measure the distance to the substance’s surface.

- Microwave Barrier: Utilizes microwave signals to detect the level of the substance.

- Guided Wave Radar: Uses radar waves guided along a probe to measure the level of the substance.

- Piezoresistive: Measures the resistance change in a piezoresistive element due to the substance’s pressure.

- Pressure Differential: Compares the pressure at the bottom and top of the substance to determine the level.

- Paddle: A paddle is immersed in the substance, and its movement is used to determine the level.

- Servo: Employs a servo motor to position a probe, which indicates the level.

- Radiometric: Utilizes the absorption or scattering of gamma or neutron radiation to measure the substance’s level.

- Vibronic: Utilizes vibrating forks to measure the level by changes in vibration frequency.

The choice of level measurement method depends on factors like substance characteristics, container material, accuracy requirements, environmental conditions, and the specific application’s demands. Selecting the appropriate level instrumentation is crucial to ensure reliable and precise level measurements for effective process control and management.

Direct and Indirect Level Measurement

Direct Level Measurement:

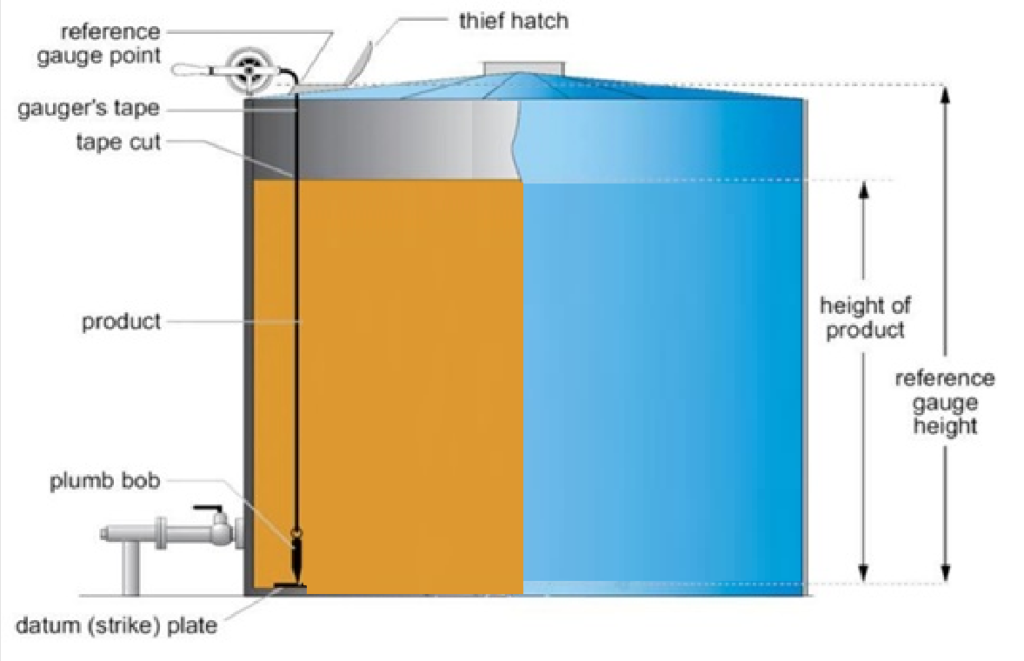

Direct level measurement is a straightforward process that relies on physical principles, such as fluid motions, floats, and thermal properties, to determine the level of a substance in a container. Various types of level measurement fall under this category, including sight glass, float-operated devices, dipsticks, dip rods, and lead lines. In direct level measurement, the position of the substance’s interface is directly determined without being restricted by the density of the material being measured.

Indirect Level Measurement:

Indirect level measurement, on the other hand, involves measuring other quantities, such as volume, to determine the level of the substance in the container. This method utilizes parameters like pressure, weight, or temperature to infer the level indirectly. However, indirect level measurement may not be suitable for measuring different materials unless a corrosive factor is considered or the instrument is recalibrated accordingly.

Level Measurement Selection Guide In Process Industry

- Level measurement techniques can be broadly categorized into three groups as follows:

- a. In the first group, level is measured directly by the means of dip sticks, sight glasses or float actuated mechanism

- b. The second group operates on the general principle that the pressure exerted at the bottom of the tank or vessel depends only on the depth and density of the liquid. If the tank is closed, vapor pressure shall be considered. If density is constant, the level of the liquid is directly related to the pressure. Examples of this type are dip tube and D.P. transmitters.

- c. The third group covers electrical/electronic methods, for example displacer type, capacitance probes and ultrasonic, nucleonic, tuning fork, radar type, load cell, electrical conductivity and optical methods

- Continuous measurement and remote readout of levels in solids bins is a more recent development.

- Many level devices, for example fiberoptics (thermal and inductive) have been recently introduced into the market, for point measurement. A laser device is available for continuous level measurement of high-temperature fluids such as molten metal and glass. Some of these devices are not yet fully tested in many industrial applications.

Level Indication

Level can be indicated continuously or point indicated. An example of continuous indication is a float in a tank connected by a cable to an indicator on the side of the tank. An example of point measurement is a sump pump level switch. It recognizes only two conditions, level above a certain point and level below a second point. Sonic, vibrating reed, and rotating paddles are other examples of point measurement.

Level Transmitters

Almost every type of continuous level-measuring device can be obtained in transmitter form. The most popular process transmitters are the differential pressure and displacer types.

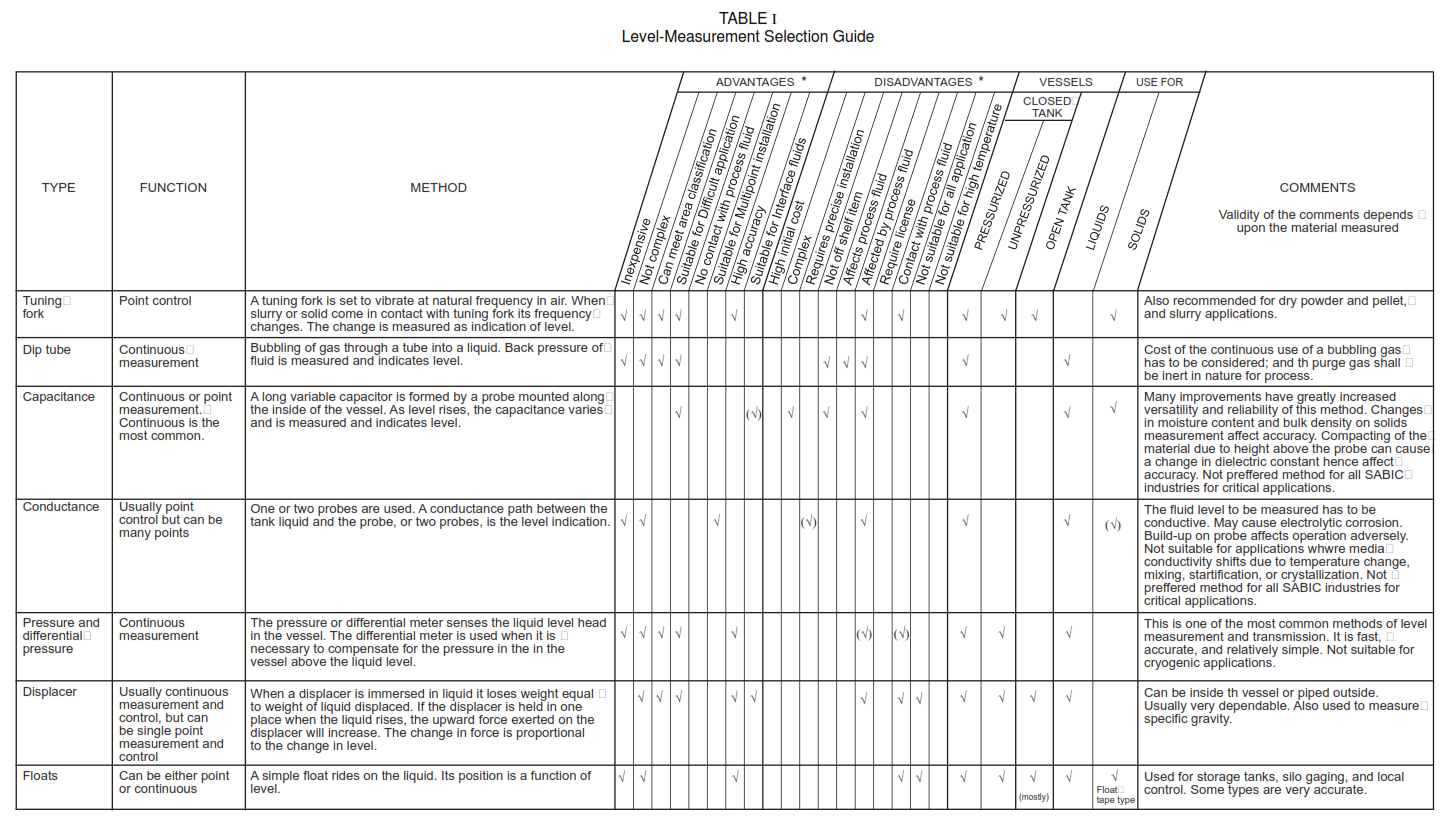

Level Measurement Selection Guide

Table I is an aid in the selection of a suitable measuring device for many applications. The numbers and letters in the fourth column refer to the advantages and disadvantages listed below.

Notes:

√ A check within parentheses indicates the comment may or may not apply, depending upon details of the application.

How to select a level instrument for our applications?

Selecting the right level instrument for specific applications requires careful consideration of various factors. Here are the key points to consider:

- Tank Type: Determine whether the tank is open or closed. Certain level instruments are more suitable for open tanks, while others are designed for closed tanks.

- Measurement Type: Decide whether a direct or indirect level measurement is needed. Direct measurement provides real-time level data based on physical properties, while indirect measurement uses other parameters like pressure or weight to infer the level.

- Material: Consider the nature of the material to be measured – whether it is a liquid, solid, slurry, or granular substance. Some level instruments may be more appropriate for specific materials.

- Continuous vs. Point Measurement: Determine if continuous level monitoring is required or if point measurements at specific intervals are sufficient for the application.

- Placement: Consider how the level instrument will be installed in the tank. Decide if it can be inserted directly into the tank (contact measurement) or if non-contact measurement is preferable.

- Environmental Conditions: Take into account the operating environment, including temperature, pressure, and potential exposure to corrosive or hazardous substances.

- Accuracy and Range: Evaluate the required level measurement accuracy and the range of levels that need to be measured. Choose an instrument that can provide the desired precision and range.

- Communication and Integration: Consider the integration of the level instrument into the existing control or monitoring system. Determine the compatibility of the instrument with the communication protocols used in the facility.

- Maintenance and Calibration: Assess the maintenance requirements and the need for periodic calibration to ensure the accuracy and reliability of the level measurements.

- Cost and Budget: Evaluate the cost-effectiveness of the level instrument, considering its features, performance, and long-term benefits for the specific application.

By carefully considering these factors, engineers and operators can select the most suitable level instrument for their applications, ensuring efficient and reliable level measurement in various industrial processes and systems.

Level Measurement Advantages

- Inexpensive.

- Not complex.

- Can be made intrinsically safe in Class I, any division, any group.

- Can be designed for difficult applications, for example very hot, dirty, corrosive, or cryogenic.

- No part of the level instrument is in contact with the process fluid.

- Can be used for multipoint installation.

- High accuracy.

- Can be used for interface measurement.

Level Measurement Disadvantages

- High initial cost.

- Complex.

- Requires unusual precautions for a safe installation.

- Not an off-the-shelf item; requires engineering to the application.

- Introduces foreign material into the process.

- Coating with process fluid, residue, or dirt may affect accuracy or cause plugging.

- May require a special Nuclear Regulatory Commission license.

- Moving parts of the level instrument are exposed to the process fluid.

- May not be applicable to agitated vessel installations.

- Not suitable for high-temperature application.

- Shall be protected against mechanical damage.