The SAES-L-131 standard outlines supplementary fracture toughness requirements for controlling crack propagation at temperatures above 0°C in carbon steel line pipes used for off-plot transportation piping. These line pipe are typically utilized in various applications, including cross-country pipelines, flowlines, trunklines, and testlines, all of which are defined in SAES-L-100. The standard’s requirements are applicable to line pipes with wall thicknesses ranging from 6.35 mm to 38.1 mm (0.25 to 1.5 inches). These line pipes must conform to API SPEC 5L, 01-SAMSS-035, and 01-SAMSS-333 standards.

In essence, SAES-L-131 sets forth specific criteria and guidelines for ensuring that the line pipes used in off-plot transportation piping can withstand the stresses and conditions they encounter during their operational life, particularly concerning crack resistance and fracture toughness at temperatures above 0°C. These requirements are essential to maintain the integrity and safety of the transportation systems that rely on these line pipes.

SAES-L-131Industry Codes and Standards

American Petroleum Institute

API SPEC 5L/ISO 3183:2007 Specification for Line Pipe

Line Pipe Fracture Control

This article outlines the classification and testing requirements for line pipe, particularly focusing on Class IV line pipe, which is used for various types of fluid services including gas, two-phase flow, and liquids such as NGL (Natural Gas Liquids) with a vapor pressure that may exceed 690 kPa (100 psia). Here are the key points:

Classification:

- Class IV Line Pipe is designated for the mentioned services, incorporating the previous Class II and Class III classifications.

- Class I was originally for liquid lines with vapor pressure up to 690 kPa (100 psia) but is no longer in use since PSL 2 pipe ordered to API SPEC 5L meets its toughness requirement.

- Class III was initially for buried gas pipelines.

- Class II has been used for liquids like NGL with high vapor pressure.

Testing Requirements:

- Class IV pipe must undergo testing as per 01-SAMSS-035, including Charpy V-notch tests on parent metal, heat-affected zone, and weld metal.

- The Charpy V-notch absorbed energy values (based on transverse specimens) must meet or exceed specified values at 0°C. These values should not be less than the minimum required for PSL 2 pipe according to API SPEC 5L.

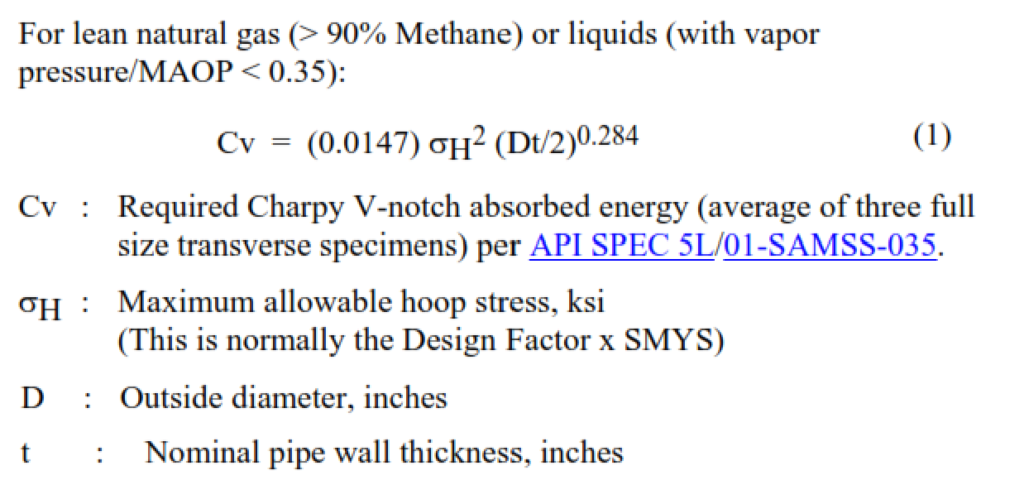

- The required energy value (Cv) is calculated using a formula, primarily based on the maximum allowable hoop stress, pipe diameter, and nominal wall thickness.

Specimen Orientation:

- All specimens for testing should be oriented transverse to the rolling direction. This orientation follows the specifications outlined in API SPEC 5L/ISO 3183, with an exception for spiral-welded (helical seam) pipe where specimens should be oriented transverse to the rolling direction of the skelp (perpendicular to the helical seam).

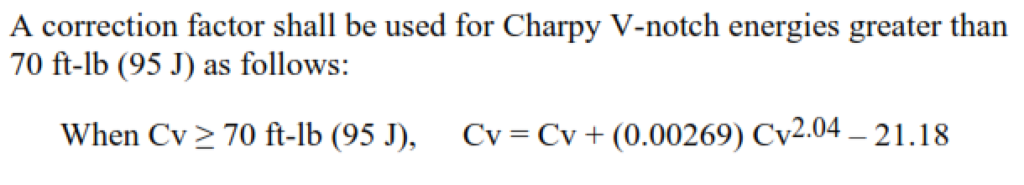

The Article also provides formulas and information for specific cases, such as when dealing with rich gases or other scenarios where the standard formula might not apply. Corrections for Charpy V-notch energies greater than 70 ft-lb (95 J) are also outlined.

It’s important to follow these guidelines to ensure that line pipes are suitable for their intended service conditions and meet the necessary fracture toughness requirements.