This article is about Low Voltage IEC Armored Cable Material Selection Criteria & Design & Requirements of Electrical Power System as per International Codes and standards for Commercial Buildings, Plants and Refinery Projects.

Low Voltage IEC Armored Cable Material Selection Criteria & Design

For the purposes of this standard SAES-P-104 (Wiring methods and Materials), severe corrosive environments include:

a) Outdoor offshore locations, and

b) Outdoor onshore locations within one kilometer from the shoreline of the Arabian Gulf; all of the Ras Tanura Refinery and Terminal; and within three kilometers from the shoreline of the Red Sea. c) Location where chlorine or other corrosive chemicals are being handled d) Battery rooms”

Locations where chloride or other corrosive chemicals are being handled are also corrosive environments. In these locations, enclosures, conduit, fittings and wiring must be resistant to the chemicals present.

“Outdoor locations correspond to wet or damp locations, and indoor locations correspond to dry locations as defined by National Electrical Code Article 100.

Commentary Note 4.4:

A structure enclosed by walls on three sides only, and having a roof, is considered an outdoor location. A non-air-conditioned building is considered an indoor location. A shop that has its doors kept open to facilitate entry of vehicles is considered an indoor location.”

Wire and cable shall have copper conductors.

Low Voltage Jacketed cables shall comply with NEC or IEC 60502-1.

NEC low voltage cables shall be rated 600V, shall have a minimum temperature rating of 90° C dry / 75° C wet, and shall conform to UL standards according to the particular type (e.g., UL 1277, including its vertical tray flame test, for type TC tray cables, etc.)

IEC 60502-1 type cables shall be rated 600/1000 V, shall have a minimum rating of 85°C, and shall meet the flame test of IEC 60332-3.

Power and control conductors shall be stranded copper, except solid copper conductors 6 mm sq (10 AWG) and smaller may be used in non-industrial locations. Stranded power, control and grounding conductors shall have stranding in accordance with IEC 60228 Class 2, except flexible cords, portable cables, battery leads and motor leads may have finer stranding in accordance with appropriate UL Standards or the manufacturer’s recommendations.

Conductors of multi-conductor control cables shall be numbered or color-coded by colors other than green, green with yellow stripes, white or gray.

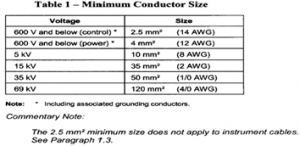

“Minimum size of conductors shall meet the requirements of Table 1.

Armored cable (unless specifically designated as Type AC per NEC Article 333) shall be manufactured to IEC 60502-1 or IEC 60502-2, and shall have galvanized steel wire armor or galvanized double steel tape armor under the jacket. For installation and application purposes, armored cable manufactured to IEC 60502-1 or IEC 60502-2 shall be considered equivalent to type MC (metal clad) cable.

“Exceptions:

A) In Class I, Division 1 and Zone 1 hazardous locations, only cables specifically permitted by NEC Article 501-4(a) are allowed without rigid steel conduit;

B) Cables terminators shall be approved for the specific type of cable used;

C) For single conductor cables, armor material shall be aluminum instead of steel.”

“Commentary Note 5.10:

Armored cable Type AC per NEC Article 333, referred to also as type BX, not to be confused with the above (C15), is light duty cable, not permitted in hazardous locations. Metal clad cable type MC per NEC Article 334 is permitted in Class I, Division 2 and Zone 2, and if listed, in Class I, Division 1 and Zone 1 locations.”

“Thickness of lapped inner coverings shall be 0.4mm for cores up to and including 40mm in diameter and 0.6mm for larger diameters.

IEC 60502-1, 7.1.4”

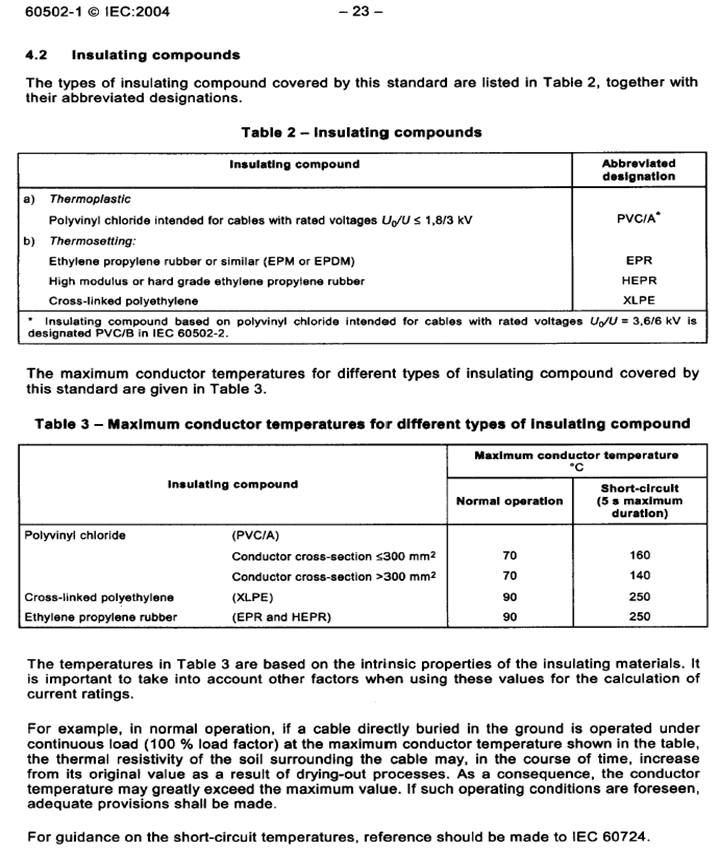

“Insulating compound shall be in accordance with Table 2.

IEC 60502-1, 4.2

(See Attachment)”

“Maximum conductor temperatures for the different types of insulating compounds shall be in accordance with Table 3.

IEC 60502-1, 4.2

(See Attachment)”

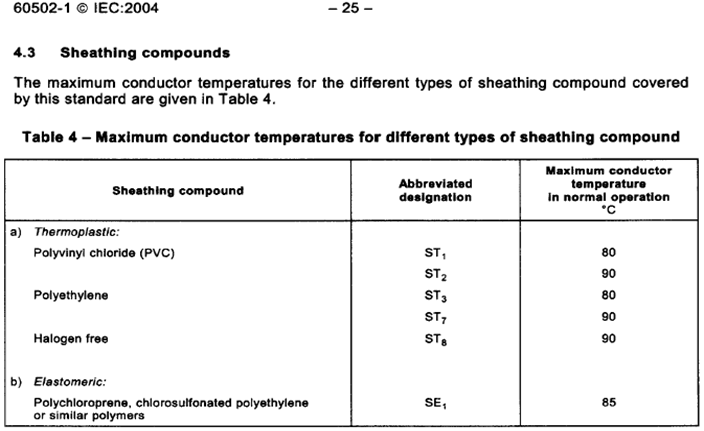

“Maximum conductor temperature ratings for the different types of sheathing compounds shall be in accordance with Table 4.

IEC 60502-1, 4.3

(See Attachment)”

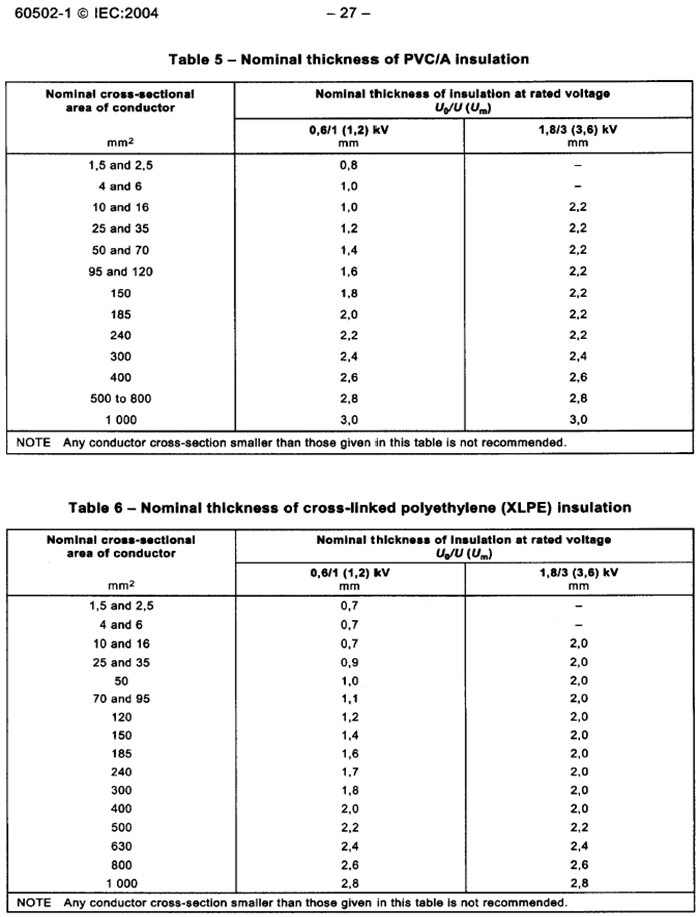

“Insulation Material and Thickness shall be in accordance with Tables 5, 6, 7.

IEC 60502-1, 6.2

(See Attachment)”

“The inner coverings may be extruded or lapped. For cables with circular cores, except cables with more than 5 cores, a lapped inner covering shall be permitted if the interstices of the cable are substantially filled. A suitable binder is permitted before application of an extruded inner covering.

IEC 60502-1, 7.1.1”

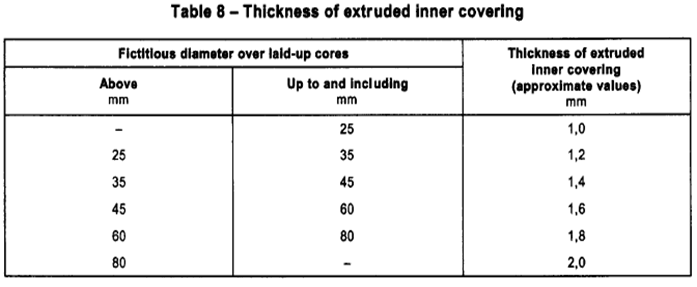

“Thickness of the extruded inner covering shall be in accordance with Table 8.

IEC 60502-1, 7.1.3

(See Attachment)”

“Thickness of lapped inner coverings shall be 0.4 mm for cores up to and including 40mm in diameter and 0.6 mm for larger diameters.

IEC 60502-1, 7.1.4”

“Cables rated 0.6/1Kv may have a metallic layer collectively surrounding the cores.

IEC 60502-1, 7.2”

“Cables shall have an inner covering over the laid up cores.

IEC 60502-1, 7.2.1”

“The metallic layer shall be in accordance with Section 8 a & d.

a) Metallic screen

b) Concentric conductor

c) Lead sheath

d) Metallic armor

IEC 60502-1, 8 (a) & (d)”

“The metallic screen shall consist of one or more tapes, or a braid, or a concentric layer of wires or a combination of wires and tapes.

IEC-60502, 9.1”

“The metallic armor shall consist of Flat Wire Armor, Round Wire Armor or Double Tape Armor.

IEC 60502-1, 12.1”

“Flat Wire Armor, Round Wire Armor, or Tape Armor shall be of galvanized steel.

IEC 60502-1, 12.2”

“For multi core cables, armor shall be applied on an inner coverings of extruded or lapped.

IEC 60502-1, 12.3.2”

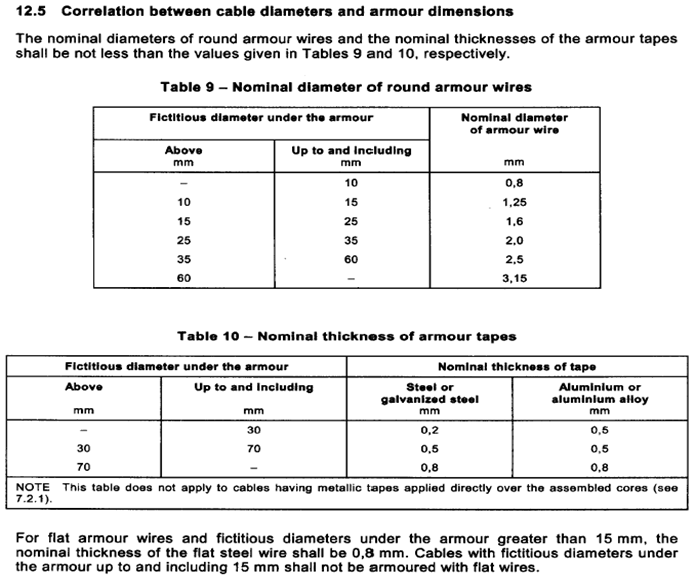

“The nominal diameters of wires and thickness of tapes shall not be less than the values given in Tables 9 and 10 respectively.

IEC 60502-1, 12.5

(See Attachment)”

“Wire armor shall be closed, an open helix of galvanized steel tape at least 0.3 mm may be provided over flat or round wire, if necessary.

IEC 60502-1, 12.6 ”

“When a tape armor and an inner covering are used, the inner covering shall be reinforced with a taped bedding.

IEC 60502-1, 12.7”

“All cables shall have an oversheath. The oversheath is normally black, but a color other than black may be provided subject to the suitability for the environment.

IEC 60502-1, 13.1”

“The oversheath shall consist of a thermoplastic compound and shall be suitable for the operating temperature in accordance with Table 4.

IEC 60502-1, 13.2

(See Attachment)”

“Thickness of the oversheath shall be in accordance with the formula, ts = 0.035 D+1.0, nominal thickness shall be not less than 1.8 mm.

IEC 60502-1, 13.3”

International Standard and Codes for Low Voltage IEC Armored Cable

- Non-Hazardous Indoor Enclosures, Installation and Pre-Commissioning

- Boxes, Enclosures, and Accessories Materials Selection & Requirements

- 3. SAES-P-104 Wiring Methods and Materials, 13 January 2008

4. IEC 60502-1, Power Cables with Extruded Insulation and their Accessories for Rated Voltages from 1 kV up to 30 kV – Part 1: Cables for Rated Voltages of 1 kV and 3 KV, April 2004ATTACHMENT(S):

1. IEC 60502-1 Power Cables with extruded insulation and accessories for rated Voltages from 1 KV up to 30 KV, Tables 2, 3, 4, 5, 6, 7, 8, 9 & 10