- PURPOSE

- SCOPE

- APPLICABLE DOCUMENTS

- RESPONSIBILITY

- MANPOWER

- TOOLS & EQUIPMENT

- METHODS/PROCEDURES

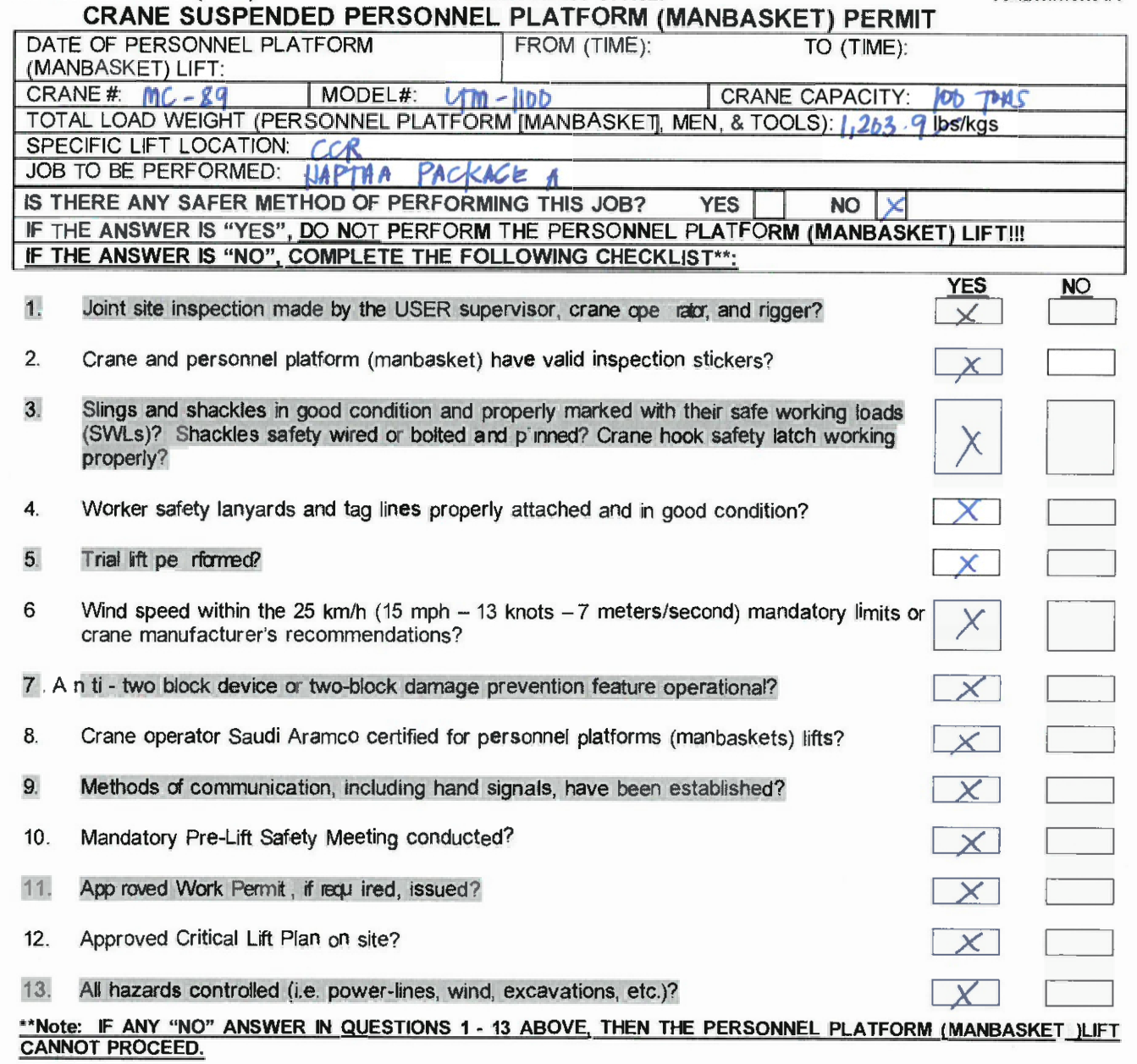

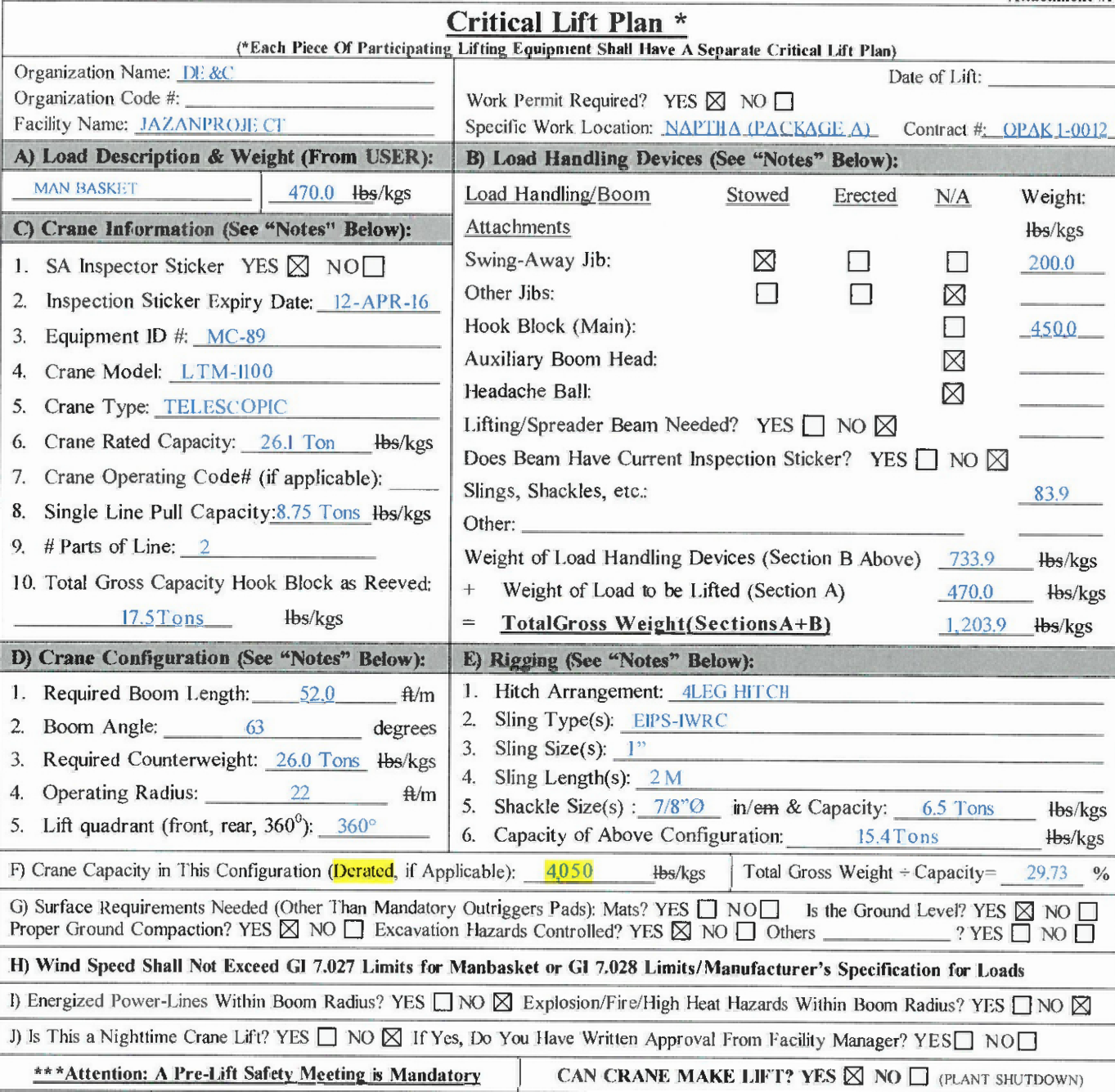

- SAFETY PRECAUTION

- ATTACHMENTS

1.0 PURPOSE:

1.1 This method statement shall provide minimum Guidelines for Manbasket Operation in accordance with Saudi Aramco Standards.

2.0 SCOPE:

2.1 This specification covers the minimum requirements for Manbasket Operation. Manbasket will be utilizing to Towers / Vessels (dress-up), High Structures (CCR) and etc. to be applied at plants and refinery.

3.0 APPLICABLE DOCUMENTS:

3.1 Project Specifications and Standard

3.1.1 SAEP-302 Instruction for obtaining a waiver of a mandatory Saudi ARAMCO Engineering requirement.

3.2 Saudi ARAMCO Safety, Health and Environmental Standard:

3.2.1 Construction safety manual — compliance with schedule D.

3.2.2 General Instructions (G.l’s) at the work site.

3.2.2.1 GI 7.027 Crane suspended personnel platform (manbasket) operations

4.0 RESPONSIBILITY:

4.1 Construction Manager is responsible for implementation of all HSE requirements; he shall study, analyze and schedule all construction activities with his department to include manpower and equipment line up as well as other possible resources

required for the successful implementation of the construction work activities. Study all aspects of work procedure as per Saudi Aramco Standards and Procedures.

4.2 Certified Saudi Aramco Rigger I is responsible for all rigging activities. He shall study and review all necessary documents such as rigging plans and critical lift plan.

4.3 Certified Saudi Aramco Rigger II is responsible to prepare a load for lifting.

4.4 Safety Engineer/Supervisor shall be responsible in monitoring safety aspects and ensuring that the work is done in accordance with Saudi Aramco Standards and Safety Standard Procedure. He shall discuss potential hazards and give reminders to workers as an additional point to work safely.

5.0 MANPOWER

5.1 The Rigger I shall control the overall activity on utilizing the manbasket. The basic manpower under him shall consist but not limited to the following:

5.1.1 Rigger II (Aramco Certified)

5.1.2 Rigger Ill (Aramco Certified)

5.1.3 Crane Operator (Aramco Certified)

5.1.4 Helper

5.2 Safety Engineer

6.0 TOOLS AND EQUIPMENT;

6.1 Tools and equipment needed should be in good condition and must be checked by

Line of Supervision/Safety Officer prior to use in the construction area. These

Includes but not limited to:

6.1.1 Certified sling and hoists

6.1.2 Rigging accessories

6.1.3 Crane

6.1.4 Tag line nylon rope

6.1.5 Manbasket

7.0 MANBASKET OPERATION METHOD STATEMENT / METHODS/ PROCEDURES:

7.1 Inspection of Manbasket & Rigging accessories

7.1.1 Upon receiving manbasket, all parts of manbasket must be in good condition.

7.1.2 Any defects found during inspections which create a safety hazard shall be corrected before utilizing.

7.1.3 Check valid inspection sticker.

7.1.4 Slings and shackle in good condition and properly marked with their safe working loads (SWLs).

7.1.5 Manbaskets shall have a safe working capacity based on a minimum design safety factor of 5:1.

7.1.6 Crane hook safety latch working properly.

7.1.7 Perform Proof Load Test of 200% of the rated capacity. This shall be done by floating the crane suspended manbasket and test weight approximately 31 cm (12 inches) from the ground for five minutes.

7.2 Preparatory Works

7.2.1 Secure work permit from DEC/JGC representative prior to start of work/activity.

7.2.2 Prepare all materials, tools and equipment needed for the job.

7.2.3 Provide matting if required.

7.2.4 Position required crane on the activity area

7.2.5 Install barricades to confine the area for authorized personnel only.

7.2.6 Prepare lifting location where the crane will be positioned.

7.2.7 Checked wind condition, lift shall not proceed when wind velocity is greater than required of crane manufacturer’s recommendation or wind speed must within the 25 km/h (15mph – 13knots – ?meters/second).

7.2.8 Trial lift must be performed.

7.2.9 Anti-two block device or two-block damage prevention feature must be operational.

7.2.10 Methods of communication, including hand signals, must be established.

7.2.11 Pre-lift safety meeting must be conducted.

7.2.12 Approved critical lift plan must be provided prior to execution of work.

7.2.13 All hazards controlled (i.e. power-lines, wind, excavations, etc)

7.2.14 Person involve in the activity must wear all times the approved full body harness and approved safety lanyard attached to designated locations on the manbasket.

7.3 Manbasket Operation (TowerNessel and CCR Structure)

7.3.1 Workers shall keep all part of the body inside the manbasket during hoisting and lowering operations.

7.3.2 Crane operator will slowly or gradually hoist up the manbasket with no sudden movements of the crane or derrick, or the manbasket itself.

Note: Do not lift or lower an occupied manbasket at a speed in excess of 30.5 meters/minute (0.5meters/second-100 feet/minute.)

7.3.3 The load and boom hoist drum brakes, swing brakes, and locking devices will be engaged once the manbasket is in stationary working position.

7.3.4 Person involve on the activity must hook lanyard at all times to the manbasket and or structure by the use of proper fall arrest equipment.

7.3.5 Workers shall proceed on their activity upon reaching on the position required.

7.3.6 Upon completing the activity, crane operator will slowly lower the manbasket until manbasket reaches on the ground.

8.0 SAFETY PRECAUTION

8.1 Obtain the approval of the work permit from the concerned Representative before starting any work:

8.2 Work execution shall be carried out in accordance with method statement. And in compliance with Saudi ARAMCO General Instruction G.1.7.028 and G.1.7.027, Crane Lifts; Types and Procedure.

8.3 Man basket will be inspected by safety supervision prior to execution of activity.

8.4 Continuous monitoring and inspection shall be implemented to detect and correct unsafe practices while performing the work activities.

8.5 Provide warning sign and sufficient barricade on working area and only assigned personnel will be allowed in the area.

8.6 Worker shall wear PPE’s needed for the work.

8.7 All rigging equipment shall be in good condition and possess a valuable certificate from authorized certifying and inspection department. In compliance with Saudi ARAMCO General Instruction G.1.7.030 Inspection and Testing Requirements for Elevating/lifting Equipment.

8.8 Safety Supervisor/Officer shall monitor the work activities to help and to protect all assigned workers against exposure to safety hazards. He shall ensure that Personal Protective Equipment (PPE’s) are supplied and used and comply with applicable standards.

8.9 Housekeeping shall be maintained and working area shall be kept in a clean and tidy manner.

8.10 Job Hazard and Risk Assessment (JHRA) of this method statement shall be disseminated and explained to workers for safety awareness.

9.0 ATTACHMENT:

9.1 Attachment A Job Hazard and Risk Assessment (JHRA)

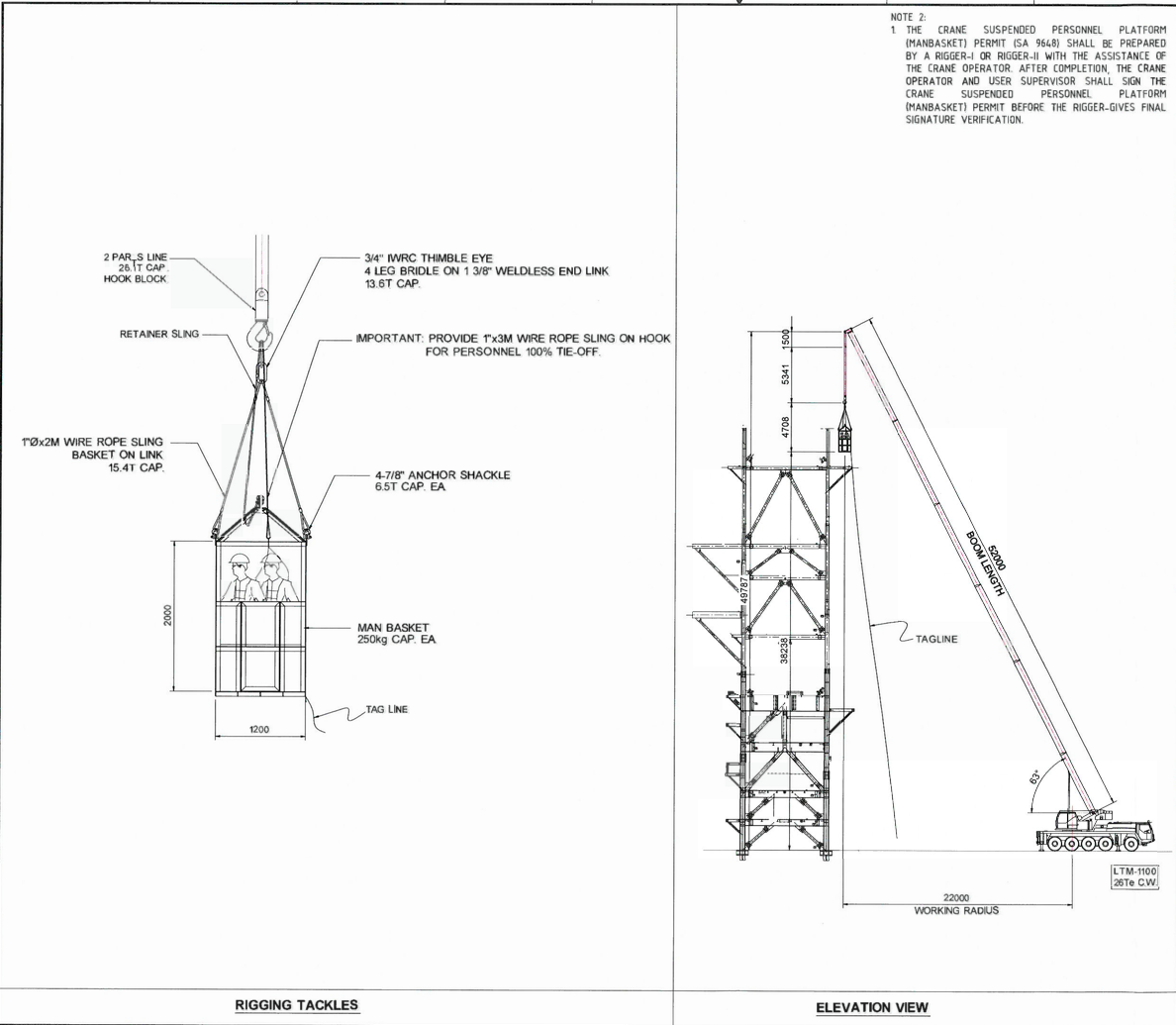

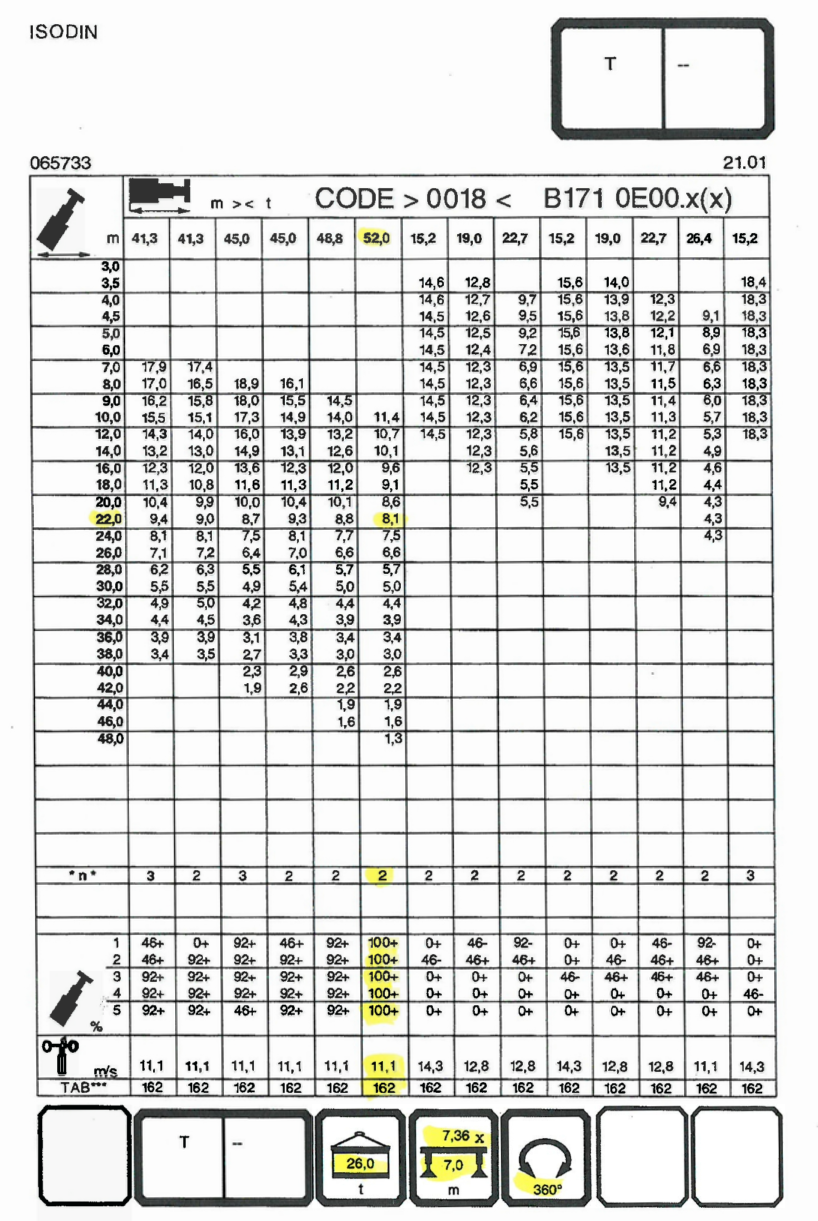

TYPICAL LIFTING PLAN OF MANBASKET AT CCR

NOTE 1

1. ALL DIMENSIONS ARE IN MM. UNLESS NOTED OTHERWISE.

2. REFER TO RATED LOAD CHARTS FOR CRANE CAPACITIES.

3.WORK IN-CHARGE SHALL VERIFY ALL DIMENSIONS AND CHECK SITE CONDITION PRIOR COMMENCING WITH THE WORK. ANY ERRORS, OMISSIONS OR UNUSUAL CONDITION SHALL BE REPORTED TO THE RIGGING ENGINEER IMMEDIATELY.

4. PROVIDE TAG LINES PRIOR TO LIFTING 5. THIS RIGGING PLAN WAS PREPARED BASE ON AVAILABLE DRAWINGS AND INFDRMA TION, REQUIREMENT TO SUITE ACTUAL CONDITION UPON DELIVERY OF EQUIPMENT SHALL BE CORRECTED ON SITE WITH CLIENT REPRESENTATIVE CONSENT

6. PROVIDE 1M » 2M + 25MM STEEL PLATE SHALL PLACE UNDERNEATH CRANE OUTRIGGERS.

7. RIGGERS AND CRANE OPERATORS MUST HAVE AN ARAMCO CERTIFICATION.

NOTE 2:

1. THE CRANE SUSPENDED PERSONNEL PLATFORM (MANBASKET) PERMIT (SA 9648) SHALL BE PREPARED BY A RIGGER-I OR RIGGER-II WITH THE ASSISTANCE OF THE CRANE OPERATOR. AFTER COMPLETION, THE CRANE OPERATOR AND USER SUPERVISOR SHALL SIGN THE CRANE SUSPENDED PERSONNEL PLATFORM (MANBASKET) PERMIT BEFORE THE RIGGER-GIVES FINAL SIGNATURE VERIFICATION.