This article is about Medium Voltage UL / NEC Cable Material Selection Criteria, Design & Requirements of Electrical Power System as per International Codes and standards for Commercial Buildings, Plants and Refinery Projects.

Medium Voltage UL / NEC Cable Material Selection Criteria & Design

Certifications For UL/NEC Cables

Medium Voltage Power Cable shall be manufactured and tested in accordance with Association of Edison Illuminating Companies (AEIC) CS8.

Cable shall be manufactured and tested in accordance with AEIC CS8 and ICEA S-97-682 (cable without concentric neutral), or in accordance with AEIC CS8 and ICEA S-94-649 (concentric neutral cable).

The outer jacket shall meet the sunlight resistance, and the oil resistance I or II requirements of UL 1072. A certificate from the manufacturer that the cable has been type tested by a third party and that it meets these UL tests is acceptable in lieu of formal UL listing or certification.

The cable shall meet the vertical tray flame test specified in UL 1072. A certificate from the manufacturer that the cable has been type tested by a third party and that it meets this UL test is acceptable in lieu of formal UL listing or certification.

Medium-voltage cables meeting the requirements of 15-SAMSS-502 are suitable for use in Class I, Division 2 and Zone 2 locations.

General Material Requirements

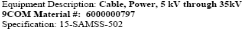

Acceptable Manufacturers – The list of acceptable manufacturers of MV Power Cable is as shall in Table.

Substitution of AEIC cable with IEC cable or vice versa is prohibited.

New and Unused – Electrical materials shall be new and unused.

As Designed – Electrical materials shall be in accordance with the Saudi Aramco-approved project-specific design drawings, diagrams, schedules, lists, databases, and associated documents.

Free of Damage – Electrical materials shall be free of damage. Cable ends are not damaged. Factory-sealed ends or factory installed pulling eyes, if installed, are intact.

QC Before Installation – Electrical materials shall conform to all applicable requirements, standards, and specifications prior to release to be used as part of the work. Upon receipt on-site, the cable shall be tested on reels for continuity and insulation resistance.

Identification – Electrical materials shall be identified by using tags, stamps, color coding, stencils or labels. The location and method of identification shall not affect the function or quality of the materials.

Traceability – Electrical materials shall be traceable from the manufacturer and supplier through delivery, storage, fabrication, erection, installation, repair, modification and use.

Each phase of multi-conductor cables shall be permanently identified.

“Cables shall be marked on the outer non-metallic sheath (jacket) at intervals not exceeding 1 m with the following information:

1) Rated voltage

2) Insulating compound (XLPE or EPR)

3) Number, size and material (“”COPPER”” or “”CU””) of conductors

4) Manufacturer’s name

5) Year of manufacture”

Reels shall be made of steel, or, alternatively, shall be heavy duty wood reels. Reels shall be lagged with wood, and shall be marked with a durable label securely attached to a flange of the reel and plainly stating Buyer’s Purchase Order number, shipping length of cable on reel, number, type and size of conductors, cable configuration, and voltage rating. Cable ends shall be sealed and capped.

“Additional Optional Water and Water Tree Protection

One or more of the following shall be provided, if specified:

1. Longitudinal water protection, in the form of semiconducting water blocking swellable tapes applied under and over the metallic screen or concentric neutral.

2. Longitudinal water protection for the conductors, in the form of strand sealant.

3. Radial water ingress protection, in the form of plastic coated laminated aluminum or copper tape immediately under the outer jacket and firmly bonded to it.

4. Tree-Resistant XLPE (TRXLPE) instead of XLPE insulation.”

“Minimum size of MV cable shall be as follows: (Table -1)

Voltage Size

5 kV 10mm² (8 AWG)

15 kV 35mm² (2 AWG)

35 kV 50 mm² (1/0 AWG) ”

Maximum size of conductors rated below 69kV shall be 500mm² or 1,000 kcmils.

MV-105 cable (e.g., EPR insulated cable 105ºC) shall be sized as a 90ºC rated cable ( using 90ºC ampacities and derating factors).

Specific Material Requirements

Insulation material shall be XLPE or EPR, as specified. Thermoplastic insulating compounds are not acceptable.

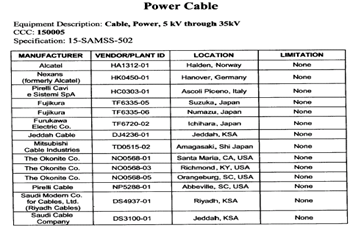

The rated voltage, nominal insulation thickness of the cable shall be in accordance with the table below.

The conductors shall be ASTM B8 Class B concentric-lay-stranded annealed copper, or ASTM B496 compact round concentric-lay-stranded annealed copper, plain or metal coated as specified in the purchase order.

Conductor and insulation shields are required for all cables, except 5 kV rated cable type MC may be without insulation shield if so specified.

Conductor shield shall be easily removable from the conductor, and shall consist of either a layer of extruded semiconducting compound, or a layer of extruded semiconducting compound over a semiconducting tape.

The non-metallic part of the insulation shield shall consist of a layer of extruded semiconducting compound. Semiconducting coatings (paints) are not allowed. The extruded compound shall be removable (strippable).

The extruded semiconducting conductor shield, the insulation, and the semiconducting insulation shield shall be applied by simultaneous triple extrusion. Steam curing is not acceptable for XLPE insulated cable.

The metallic part of the insulation shield shall consist of copper tape(s), and shall be applied separately over each of the semicon-shielded, insulated conductors. Copper tape shall be a minimum of 0.125 mm (5 mil) thickness, applied with a minimum of 20% overlap.

If a concentric neutral conductor is specified in the purchase order (occasionally referred to by type URD or UD cable), it shall consist of copper wires with the specified cross section, and shall be plain or metal coated as specified. Applicable standards for cables with concentric neutral are ICEA S-94-649 and AEIC CS8. The concentric neutral conductor shall be under the outer jacket. The concentric neutral wires may serve as, and take the place of the copper tape screen (shield).

Concentric neutral wire, metallic armor, and metallic sheaths shall be protected with a PVC or equivalent jacket.

ASTM B8 Class B concentric-lay-stranded annealed copper, or ASTM B496 compact round concentric-lay-stranded annealed copper ground conductor(s) shall be provided in the interstices of the cable, if specified in the purchase order.

Fillers (extruded material or non-hygroscopic fibers) shall be used in order to ensure the cable is compact and round in cross-section.

“Metallic cover, when specified in the purchase order, shall be corrugated impervious aluminum sheath, or galvanized steel interlocked tape. The cable shall be type MC (metal clad).

Exception:

Steel shall not be used for single conductor cables.”

All cables shall have a continuous overall outer nonmetallic jacket.

The outer jacket shall be PVC, suitable for 90°C maximum rated conductor temperature.

Cables shall be suitable for direct burial and for installation in duct banks, above grade rigid steel conduit and cable trays.

“In addition to the marking requirements of Section 8.2 above, the cable outer jacket shall have the following markings:

i) Insulation thickness (preferably), or % insulation level.

ii) TYPE MV-90, or, when applicable, TYPE MV-90 OR MC, or TYPE URD, or TYPE UD.

iii) OIL RES I or OIL RES II.”

International Standard and Codes for Medium Voltage UL / NEC Cable

- Non-Hazardous Indoor Enclosures, Installation and Pre-Commissioning

- Boxes, Enclosures, and Accessories Materials Selection & Requirements

- SAES-P-101 Regulated Vendors List for Electrical Equipment, 09 June 2007

- SAES-P-104 Wiring Methods and Materials, 13 January 2008

- 15-SAMSS-502 Medium Voltage Power Cable 5 kV through 35 kV, 02 August 2006

- NFPA 70 National Electrical Code (NEC), 2008 Edition

- ASTM B8 Concentric-lay-Stranded Copper Conductors, Hard, Medium Hard, or Soft

- ASTM B496 Compact Round Concentric-Lay -Stranded Copper Conductors

- AEIC CS8 Specification for Extruded Dielectric, Shielded Power Cable Rated 5 through 46 kV

- UL 1072 Standard for Medium Voltage Power Cable, 2007 Edition