This article is about Methods of Laying and Sawing Timber – Lumber Grading related to topic of Lumber Grading, Construction Grades, Redwood Grade Marks, Finish Grades, Interpreting Grade Marks, Plywood – Basic Grade Marks, Wire and Sheet Metal Gages for Project in Building, Plants and Petrochemical Plants as per International Codes & Standards.

Methods of Laying and Sawing Timber – Lumber Grading

Methods of Laying and Sawing Timber - Lumber GradingINTERPRETING GRADE MARKS

Most grade stamps, except those for rough lumber or haavy timbers contain five basic elements

(a Certification mark of certifying association of lumber manufacturers

(b) Mill identification firm name, brand or as signed mill number.

(c) Grade designation – Grade mane. number or abbreviation

(d) Species identification. indicates species by individual species or species combination.

(e) Condition of seasoning indicates condition of seasoning at time of surfacing

S-DRY – 19% maximum moisture content

MC15 – 15% Maximum moisture content

S-GRN – Over 19% moisture content (unseasoned )

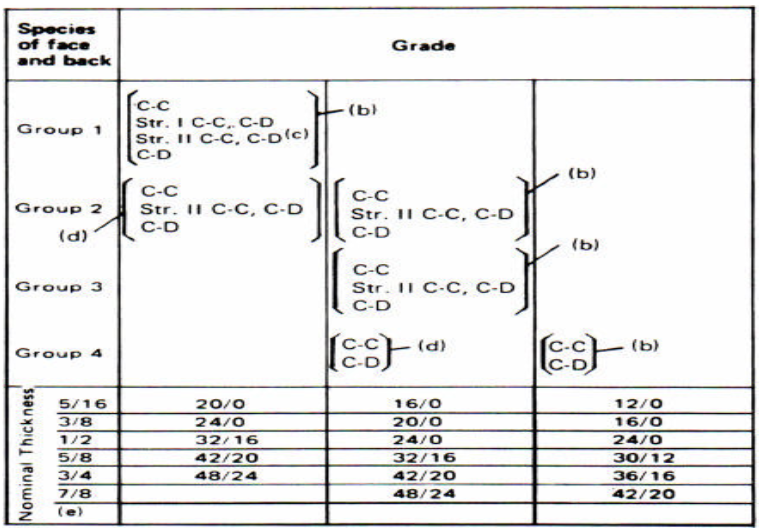

Table for Sheathing Panels

(a) Identification Index refers to the numbers in the lower portion of the table which are used in the marking of sheathing grades of plywood. The numbers are related to the species of panel face

and back veneers and panel thickness in a manner to describe the bending properties of a panel. They are particularly applicable where panels are used for subflooring and roof

sheathing to describe recommended maximum spans in inches under normal conditions and to correspond with commonly accepted criteria. The left hand number refers to spacing of roof

framing, while the right hand number relates to spacing of floor framing. Actual maximum spans are established by local building codes.

(b) Panels of standard nominal thickness and construction.

(c) Panels manufactured with Group 1 faces but classified as Structural II by reason of Group 2 or Group 3 inner plys.

(d) Panels conforming to the special thickness and panel construction provisions of PS 1-74 (3.8.6.).

(e) Panels thicker than ‘/e inch shall be identified by group number.

Source from: Wikipedia