This article is about NON-CONFORMANCE CONTROL PROCEDURE and each professional of every field must know about this procedure to issue NCR and close NCR.

Terms and Definition Use in NCR

What is Nonconformance item

Nonconformance item shall be defined as an unfitness against the quality standard and a defect on procedure, document and a specificity causing a nonconformance product this include the physical defect, test failure, incorrect/or unconformed document and deviation from the procedures described in inspection & test procedure.

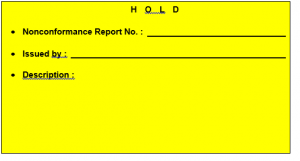

Work Hold Tag

Tag used in order to hold the following work for nonconformance item mentioned on Nonconformance report.

Use-As-Is

Act to use specially it, in case the nonconformance products are satisfied with the functional engineering requirement such as a performance, conformance, reliable maintenance.

Reject

Not to use nonconforming products by getting rid of it, and change to conformance item.

Repair

To improve and restore the nonconformance and condition within the limits of functional reliability and safety even though it is not conformed with the quality requirements.

Rework

To rework the nonconformance products by disposition, reprocessing or others to Conform with the quality requirement.

Reference

Corrective and Preventive Action Procedure

DISPOSITION OF FIELD NONCONFORMANCE ITEMS

(1) The nonconformance report system shall be operated to decide and make document the approved disposition as for the ununiformity and discrepancy of nonconformance products of the materials and services during the construction.

(2) The slight nonconformance item shall be immediately repaired at field, if the immediate repair aid to quality and progress.

(3) Nonconformance reporting format of head office has not fixed, can use the suitable method such as business communication, memorandum, VOC system, telephone etc. Direct responsible department manager for the relevant nonconformance items shall act the disposition, and answer the disposition result.

(4) If drawing modification is required by the occurrence of nonconformance, the disposition shall be followed using ‘Design Change Procedure’.

FIELD NON-CONFORMANCE CONTROL PROCEDURE

Discrimination and separation of Nonconformance product

Nonconformance product should be identified by attaching “Hold Tag” in Appendix Ⅱ. when nonconformance item has been discovered. In case that’s not easy at site, other countermeasures shall be available or it shall be separated if necessary. Only field quality engineer can attach or detach the “Hold Tag” from nonconformance product.

Quality engineer shall inform to the related construction supervisor and subcontractor verbally after attaching the “Hold Tag” to nonconformance products.

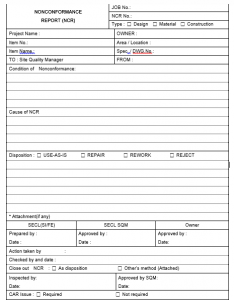

Preparation

All the staffs of client, SECL are able to prepare the NCR according to appendix Ⅲ after attaching “Hold Tag” when the nonconformance items are found at site. Field quality manager shall approve the NCR after discussion with construction supervisor if necessary.

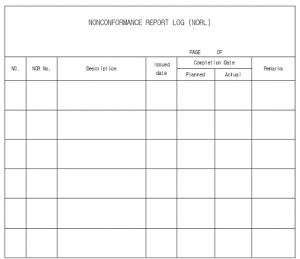

Field quality engineer should keep and control the present condition of NCR approved and registered in number.

Please check also: LIST OF INSTRUMENT AND ELECTRICAL INTERNATIONAL STANDARDS

Disposition Method of NCR

Field engineer or construction supervisor shall prepare the disposition method of NCR. A disposition shall be defined among use-as-is, reject, repair, rework on the NCR. Field quality manager shall approve the disposition method and get approval from the client if necessary.

Construction supervisor shall give a job instruction to subcontractor according to the disposition method and manage it after it is approved.

Verification for Disposition

Field quality engineer and field quality manager shall sign on the NCR as a final approval after the field quality engineer’s verifications for the NCR have been completed satisfactorily. Field quality manager shall submit the NCR and related reference documents to the client for approval if required.

Field quality engineer shall detached the “Hold Tag” from nonconformance products after completion of disposition is approved.

Corrective Action OF NCR

In case the same kind of nonconformance item is occurred continuously, quality manager shall record it on the NCR under make a decision whether corrective action request (CAR) is issued or not in order to prevent recurrence.

Nonconformance item which decided to preparing the “CAR” shall be handled according to “Disposition Procedure ”

Conditional Use

When the material/product with before accept inspection/final inspection and already decided to nonconformance item have to used for urgent purpose, it can be approved to using by field manager after get approval from client. But it can be applied in case only disposition of relevant item be not affected from the following stay progress.

The situation of item used in conditional approval shall be handled to possible to trace, and nonconforming situation shall be settled before final inspection.

NCR NUMBERING SYSTEM

N

(1) (2) (3)

Classification Discipline Serial Number

(1) Classification: Classification regarding occurred NCR field

E: Engineering, P: Procurement, C: Construction

(2) Discipline: CODE that classifies by disciplines

PO: Process CV: Civil

AR: Architecture ME: Mechanical

PP: Piping EL: Electrical

IN: Instrument PT: Painting/Coating

NS: Insulation HV: HVAC

PC: Pre-commissioning CO: Common, Others

(3) Serial number: Serial number assignment for classification and each discipline (0001∼9999)

NCR Flow chart

“HOLD” Tag

Nonconformance Report

Nonconformance Log

Responsibility & Authority

Site manager shall have responsibility and authority for the followings;

(1) Coordination Between the field engineer and construction supervisor in case of request for discussion from the field quality manager on the field quality matters.

(2) Authorizing field quality manager to manage the field quality activities.

Field quality manager shall have responsibility and authority for the followings;

(1) Total management of NCR and the activities of the nonconformances.

(2) Management of the dispositions on nonconformance report (hereinafter NCR).

(3) Transmittal of the NCR to client if necessary client’s approval.

(4) Discussion with field engineer as for the disposition of NCR.

(5) Request for discussion to site manager when the critical nonconformance subject has occurred at site that affect importantly to construction progress

(6) Session of the meeting to solve the nonconformance item.

(7) Approval of disposition completion for nonconformance item.

Field Quality engineer shall have responsibility and authority for the followings;

(1) Summarizing / management of NCR through construction, and reporting/request for approval to site quality manager.

(2) Attach & release of “Hold” tag on the nonconformance items and request construction supervisor and subcontractor’s quality engineer to separate the nonconformance item from the jobs.

(3) Confirm the disposition of NCR and report it to site quality manager.

(4) Distribute NCR to field construction supervisor and preserve it.

Construction supervisor shall have responsibility and authority for the followings;

(1) Execution of the after disposition for nonconformance items occurred at site.

(2) Supervision and coordination with a subcontractor’s quality engineer regarding the disposition of nonconformance item.

(3) Prepare NCR and inform it to field quality engineer when the nonconformance activities are found at site, and prepare disposition method when field engineer is absence.

(4) Discuss with the site manager or quality manager regarding the disposition method of nonconformance item.