This article is about Overhead Transmission & Distribution Surge Arresters Material Selection for commercial buildings, plants and refinery projects.

Overhead Transmission & Distribution Surge Arresters Checking

| QC Before Installation – Surge Arresters shall conform to all applicable requirements, standards, and specifications prior to release to be used as part of work. |

| Incoming Surge Arresters shall be visually inspected for damage / defects occurred during transportation. |

| Surge Arresters shall be checked for damage by store yard personnel prior to acceptance of shipment, unloading, or handling. No visible shipping or handling damage. (NFPA 70, NEC Art. 110.3 b and Manufacturer’s Instructions) |

| Surge Arresters shall be new and unused. |

| Surge Arresters shall be in accordance with the approved project-specific design drawings, diagrams, schedules, lists, databases, and associated design documents. |

Transmission & Distribution Surge Arresters Material Selection Guide

| Check accessories such as earthing connector, terminal lugs, Surge discharge counter for correctness and rated for application at line-to-line system voltage. |

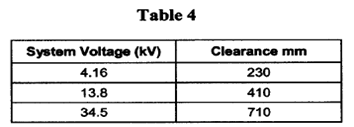

| Check that Surge arrester line and ground termination points are matching with the overhead connectors. Minimum separation between ungrounded conductors shall be per Table 4. Check also, the quantity of supplied surge arresters as per requirement. |

Minimum arrester-to-arrester clearance shall be per Table 4, if supplied three phase assembled.

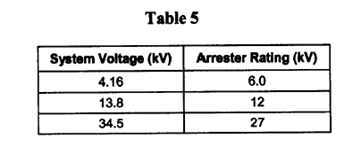

Surge arrester shall be of the distribution class, metal-oxide, gapless type rated per Table 5.

International Codes & Standards for Overhead Transmission & Distribution Surge Arresters

| SAES-P-100 Basic Power System Design Criteria |

| SAES-P-107 Overhead Distribution Systems |