Indeed, piezoelectricity is an intriguing phenomenon with a range of everyday applications. Many encounters with modern technology involve the utilization of piezoelectric materials. These materials possess a unique property: the ability to generate internal electrical charges when subjected to mechanical stress. The term “piezo,” derived from the Greek word for “push,” encapsulates this transformative capability.

A diverse array of substances found in nature exhibit the piezoelectric effect. Notable examples include bone, crystals, specific ceramics, DNA, enamel, silk, dentin, and more. This phenomenon isn’t confined to man-made materials; it’s woven into the fabric of the natural world.

What makes piezoelectric materials even more fascinating is the presence of the inverse piezoelectric effect, also known as the reverse or converse piezoelectric effect. This reciprocal phenomenon involves the internal generation of mechanical strain when subjected to an applied electrical field. In essence, these materials possess a dualistic relationship with mechanical and electrical forces, enabling them to seamlessly convert between the two.

The broad range of substances exhibiting the piezoelectric effect and its inverse underscores the interconnectedness of seemingly distinct materials and natural processes. From bones that bear the traces of this effect to the intricate mechanics of crystals, the world is replete with examples that highlight the profound influence of piezoelectricity. Whether in medical diagnostics, igniting a flame, or transmitting vibrations, the world of piezoelectric materials continues to leave an indelible mark on our daily lives.

Read Also: What is Piezoelectric Transducer? Working Principle, Types, Applications, Challenges

Piezoelectric Materials used in History:

The journey of piezoelectricity began with the exploration of crystals as the earliest materials of experimentation. In 1880, the pioneering Curie brothers, Pierre and Jacques, unveiled the direct piezoelectric effect, propelling our understanding of this phenomenon. Drawing on their insights into crystalline structures and pyroelectric materials, which generate electric charges in response to temperature changes, they embarked on a journey of discovery.

By studying specific crystals such as cane sugar, tourmaline, quartz, topaz, and Rochelle salt, the Curies were able to measure surface charges. Notably, quartz and Rochelle salt showcased the most potent piezoelectric effects. While the Curies’ work unveiled the direct piezoelectric effect, the inverse piezoelectric effect eluded their predictions. It was the mathematical prowess of Gabriel Lippmann in 1881 that deduced the inverse effect, subsequently confirmed quantitatively by the Curies themselves. This discovery demonstrated the reversibility of electric, elastic, and mechanical deformations in piezoelectric crystals.

As the field progressed, the natural crystal classes exhibiting piezoelectricity were definitively outlined by Woldemar Voigt’s “Lehrbuch Der Kristallphysik” in 1910. However, despite these strides, piezoelectricity remained confined to a specialized realm of physics without clear technological applications.

The landscape shifted dramatically during World War I, where piezoelectricity found its first practical application in the form of ultrasonic submarine detectors. These detectors utilized transducers—devices converting energy from one form to another—constructed from thin quartz crystals sandwiched between steel plates. This success kindled intensive technological growth in the piezoelectric domain, leading to the incorporation of piezoelectric ceramics in phonograph cartridges post-war.

The momentum only escalated during World War II as independent research by Japan, the USSR, and the United States propelled the understanding of the crystal structure-electromechanical activity relationship. This breakthrough marked a shift from merely observing material properties to tailoring piezoelectric materials for specific device applications. This transformation gave rise to a plethora of wartime piezoelectric applications, including super-sensitive microphones, powerful sonar devices, sonobuoys for ocean vessel monitoring, and piezo ignition systems.

In essence, the journey of piezoelectric materials from the Curie brothers’ initial experiments to their pivotal role in wartime technologies underscores the profound impact of scientific curiosity and innovation on shaping the technological fabric of our world.

Piezoelectric Materials and Different Types:

Following are different piezoelectric materials.

1. Piezoelectric polymers Materials:

Piezoelectric polymers represent a fascinating class of materials that exhibit the unique ability to generate electric charges when subjected to mechanical stress, a phenomenon known as the piezoelectric effect. Unlike traditional piezoelectric materials like crystals and ceramics, piezoelectric polymers are organic compounds composed of long chains of repeating molecular units. This distinctive characteristic offers several advantages and opens up new avenues for applications in various fields.

Here are some examples of piezoelectric polymers materials:

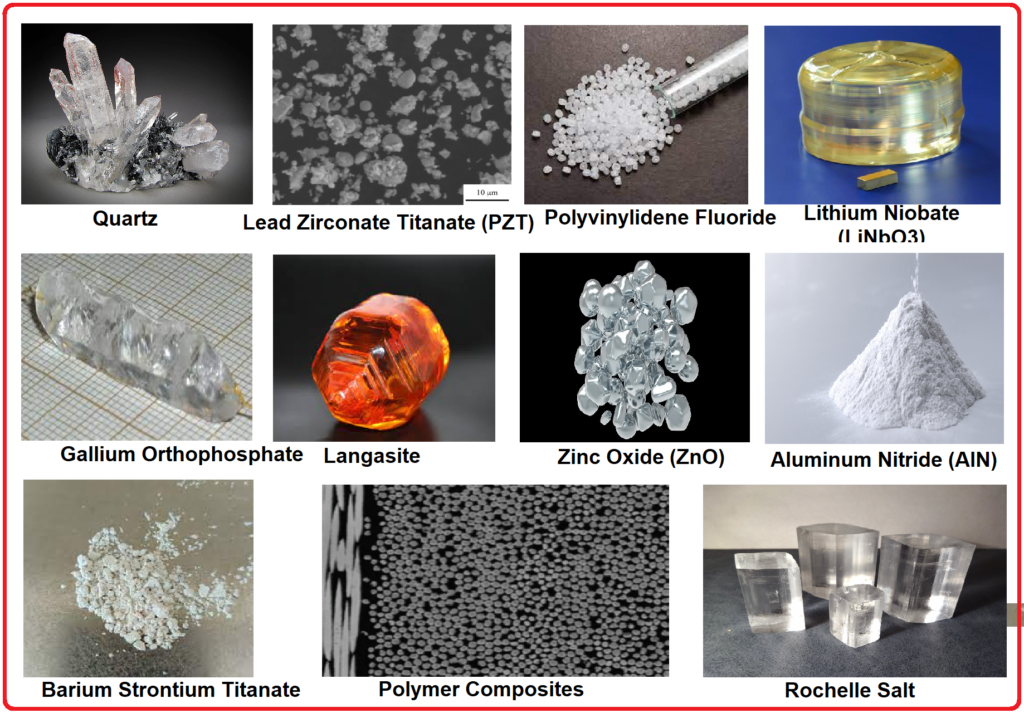

- Polyvinylidene Fluoride (PVDF): One of the most widely studied and used piezoelectric polymers, PVDF exhibits strong piezoelectric properties and is used in various applications including sensors, energy harvesters, and actuators.

- Polyvinylidene Trifluoroethylene (PVDF-TrFE): A copolymer of PVDF, PVDF-TrFE offers enhanced piezoelectric properties and is used in flexible electronics and medical devices.

- Poly(L-lactic acid) (PLLA): Biocompatible and biodegradable, PLLA-based piezoelectric polymers have potential applications in biomedical devices and implants.

- Poly(vinyl alcohol) (PVA): PVA can be modified to exhibit piezoelectric properties and is explored for use in sensors and energy harvesting.

- Polyurethane (PU): Certain types of polyurethane can demonstrate piezoelectric behavior, making them suitable for flexible electronics and wearable devices.

- Polyimide (PI): Piezoelectric polyimide films find applications in sensors and actuators, particularly in aerospace and robotics.

- Polyethylene (PE): Under specific conditions, polyethylene can exhibit piezoelectric characteristics and has been investigated for potential energy harvesting applications.

- Polyamide (Nylon): Certain types of nylon can be engineered to possess piezoelectric properties, finding use in sensors and flexible electronics.

- Polypropylene (PP): Piezoelectric polypropylene has been explored for applications in energy harvesting and sensing.

2. Naturally occurring crystals or Piezoelectric Materials:

Following naturally occurring crystals exhibit the remarkable piezoelectric effect:

- Quartz: Quartz is a widely recognized and stable crystal that finds applications in watch crystals and serves as a frequency reference for radio transmitters. Its reliability and piezoelectric properties make it an essential component in timekeeping and communication technologies.

- Sucrose (Table Sugar): While perhaps surprising, sucrose, commonly known as table sugar, possesses piezoelectric qualities. Its ability to generate electrical charge when subjected to mechanical stress adds an intriguing facet to its properties.

- Rochelle Salt: Rochelle salt stands out for its capacity to produce a significant voltage when compressed. This attribute made it a valuable material in early crystal microphones, contributing to the development of early audio technologies.

- Topaz: Topaz, a mineral known for its stunning colors, also possesses piezoelectric capabilities. Its natural piezoelectricity highlights the intricate ways in which these properties manifest in various materials.

- Tourmaline: Another naturally occurring crystal with piezoelectric properties, tourmaline, demonstrates the wide range of materials in which this effect can be found. Its unique characteristics make it a subject of interest in both scientific and artistic pursuits.

- Berlinite (AlPO4): Berlinite, a rare phosphate mineral, shares a structural similarity with quartz. Its resemblance to quartz extends to its piezoelectric behavior, showcasing the diverse forms in which this phenomenon can manifest.

The presence of the piezoelectric effect in these naturally occurring crystals underscores the intricacies of the natural world and the remarkable ways in which materials interact with mechanical and electrical forces. This phenomenon, harnessed and understood, has propelled technological advancements and continues to shape various fields of study.

3. Man-made Piezoelectric Materials:

Here are examples of man-made crystals that exhibit piezoelectric properties:

- Gallium Orthophosphate (GaPO4): GaPO4 is a synthetic crystal that serves as a quartz analog, mimicking the piezoelectric behavior of quartz. Its engineered properties make it a valuable material in applications that require precise frequency control and stability, similar to quartz.

- Langasite (La3Ga5SiO14): Langasite is another synthetic crystal that emulates the piezoelectric characteristics of quartz. Its composition and structure enable it to generate electrical charges in response to mechanical stress, rendering it useful in a variety of technological applications.

4. Piezoelectric ceramics Materials:

Here are examples of piezoelectric ceramics, both widely recognized and commonly used:

- Barium Titanate (BaTiO3): Barium titanate is historically significant as the first piezoelectric ceramic to be discovered. Its ability to generate electrical charges when subjected to mechanical stress was a pivotal discovery in the development of piezoelectric materials.

- Lead Titanate (PbTiO3): Lead titanate is another ceramic that exhibits piezoelectric properties. Its characteristics contribute to the broader understanding of piezoelectric behavior and its potential applications.

- Lead Zirconate Titanate (PZT): PZT holds a prominent place as one of the most commonly used piezoelectric ceramics. Its versatility and strong piezoelectric response make it a preferred choice in various devices, including sensors, actuators, and transducers.

- Potassium Niobate (KNbO3): Potassium niobate is recognized for its piezoelectric qualities and its potential applications in the field of electronics and acoustics.

- Lithium Niobate (LiNbO3): Lithium niobate’s piezoelectric behavior is utilized in various applications, including acoustic devices and optical modulators.

- Lithium Tantalate (LiTaO3): Similar to lithium niobate, lithium tantalate exhibits piezoelectric properties and is valuable in acoustic and optical technologies.

- Sodium Tungstate (Na2WO4): Sodium tungstate’s piezoelectric attributes contribute to its potential role in various applications where mechanical-electrical conversion is required.

These piezoelectric ceramics highlight the broad spectrum of materials engineered to harness the piezoelectric effect. Their distinctive characteristics and properties enable their integration into diverse technological applications, shaping industries ranging from electronics to acoustics and beyond.

5. Lead-free piezoceramics Materials:

Here are examples of lead-free piezoceramics that have been developed as alternatives to traditional lead-containing materials:

- Sodium Potassium Niobate (NaKNb): Developed as a lead-free alternative, sodium potassium niobate exhibits properties akin to those of PZT (lead zirconate titanate). This material offers similar piezoelectric capabilities without the environmental concerns associated with lead-based ceramics.

- Bismuth Ferrite (BiFeO3): Bismuth ferrite is another lead-free piezoceramic that has garnered attention for its potential applications. Its piezoelectric properties contribute to its use in various devices while addressing concerns about lead exposure.

- Sodium Niobate (NaNbO3): Sodium niobate serves as another lead-free option in the realm of piezoceramics. Its properties make it suitable for applications that require mechanical-electrical conversion without the use of lead-based materials.

These lead-free piezoceramics showcase the ongoing efforts within materials science to develop environmentally friendly alternatives without compromising on performance. As the demand for sustainable materials grows, lead-free piezoceramics play a pivotal role in ensuring that technology can continue to advance responsibly.

6. Biological piezoelectric materials:

Here are examples of biological materials that exhibit piezoelectric properties:

- Tendon: Tendons, the connective tissues that attach muscles to bones, have been found to exhibit piezoelectric behavior. This natural phenomenon adds an intriguing layer to the understanding of biological materials.

- Wood: Wood, a ubiquitous natural material, also possesses piezoelectric properties. This discovery underscores the intricate ways in which biological structures interact with mechanical forces.

- Silk: Silk, produced by various insects and spiders, is renowned for its strength and versatility. Its piezoelectric attributes further highlight the multifaceted nature of this biologically derived material.

- Enamel: Enamel, the hard outer layer of teeth, has been identified as having piezoelectric properties. This discovery offers insights into the unique characteristics of dental materials.

- Dentin: Dentin, the substance beneath enamel that comprises the bulk of a tooth, also exhibits piezoelectric behavior. Understanding these properties can contribute to insights into tooth functionality and health.

- Collagen: Collagen, a vital protein found in connective tissues throughout the body, has been recognized for its piezoelectric attributes. This discovery adds to the complexity of collagen’s roles in biological systems.

These biological piezoelectric materials showcase the convergence of biology and materials science, revealing the unexpected ways in which living organisms possess properties that extend beyond their biological functions. The exploration of piezoelectricity in biological materials offers potential insights into their roles within organisms and opens up possibilities for innovative applications in various fields.

What are Smart Materials?

Smart materials represent a fascinating category of materials with dynamic properties that can be purposefully altered through external triggers such as pH, temperature, chemicals, magnetic or electric fields, or stress. These materials, also known as intelligent functional materials, exhibit responsive behavior that allows them to adapt to changing conditions.

Piezoelectric materials align with the concept of smart materials due to their capacity to transform electrical signals into mechanical stress, and vice versa. This bidirectional conversion underscores their versatility and responsiveness to applied stimuli.

In addition to piezoelectric materials, the realm of smart materials encompasses a diverse array of substances, each with its own distinctive characteristics:

- Shape Memory Alloys: These materials can “remember” their original shape and return to it after being deformed, making them invaluable for applications such as medical devices and actuators.

- Halochromic Materials: These materials change color in response to changes in pH levels or other external factors, offering visual cues for various applications.

- Magnetocaloric Materials: These materials heat up or cool down when subjected to a magnetic field, showing potential for advanced refrigeration technologies.

- Temperature-Responsive Polymers: Polymers that change their properties based on temperature alterations find application in diverse fields, from responsive textiles to drug delivery systems.

- Photovoltaic Materials: Materials that convert light into electricity play a pivotal role in the realm of solar energy, offering a sustainable means of harnessing power.

The expansive variety of smart materials demonstrates the ingenuity of materials scientists and engineers in creating substances that can adapt, respond, and perform in ways that align with specific requirements. The applications of smart materials extend to fields such as electronics, medicine, energy, and beyond, shaping the landscape of technological innovation.