- PURPOSE

- SCOPE

- REFERENCES

- PROCESS OF PRESERVATION

- PRESERVATION MAINTENANCE LOG CARD AND NCR

- NITROGEN PURGING

- QUALITY CONTROL AND INSPECTION

- SAFETY INSTRUCTIONS & PRECAUTIONS

- ATTACHMENTS

1.0 PURPOSE

This Method Statement will serve as a minimum guidelines to carry out the Preservation Execution Procedure of all static and rotating equipment installed at JAZAN REFINERY & TERMINAL PROJECT (PACKAGE-12 NAPTHA AND AROMATICS).

2.0 SCOPE

This specification covers the minimum requirements for Preservation Execution Procedure of all static and rotating equipment installed at JAZAN REFINERY PROJECT scope of JGC/DEC with its main client SAUDI ARAMCO in Jizan, Kingdom of Saudi Arabia

3.0 REFERENCES

Applicable Saudi Aramco Material Systems Specifications

Manufacturer’s Recommendations

4.0 PROCESS OF PRESERVATION

4.1 Organization, Role and Responsibility

The functions of key personnel who are responsible in the preservation activities are as follows:

Site Manager shall ensure compliance by all construction personnel to this procedure including its HSE implementation.

Preservation Supervisor shall be responsible in supervising the actual preservation work of the worker, preparation of the Log Cards and actual check of preservation status based on the check points specified on each Preservation Maintenance Log Card.

QC Manager shall ensure that this procedure is implemented.

QC Inspector shall ensure that the storage, handling and preservation of the equipment are done according to this procedure.

Safety Officer shall check the work areas and monitor from time to time in the implementation of safety procedure and assuring that all safety equipment and tools are present at site and in good working condition.

4.2 Start / End and Frequency of Preservation Work

The preservation work shall start upon installation of the equipment on site and shall be in accordance with this Preservation Execution Procedure. It will also commence the recording of the status of the equipment on the Preservation Maintenance Log Card.

The equipment shall be checked based on the frequency specified on the Preservation Maintenance Log Card which is explained in para. 5.2.5 of this document. The inspection frequency can be adjusted according to actual preservation condition of the equipment and each item’s characteristic. Shall there be any discrepancy between this Preservation Execution Procedure and Manufacturer’s Recommendations, the latter shall always prevail.

4.3 Log of Preservation Work

The preservation activities are to be recorded on each relevant Preservation Maintenance Log Card and administered in a proper binder by the Preservation Supervisor assigned. All the copies of original Preservation Maintenance Log Cards shall be kept by the preservation team until completion of the construction phase and handover the same to the PreCommissioning team.

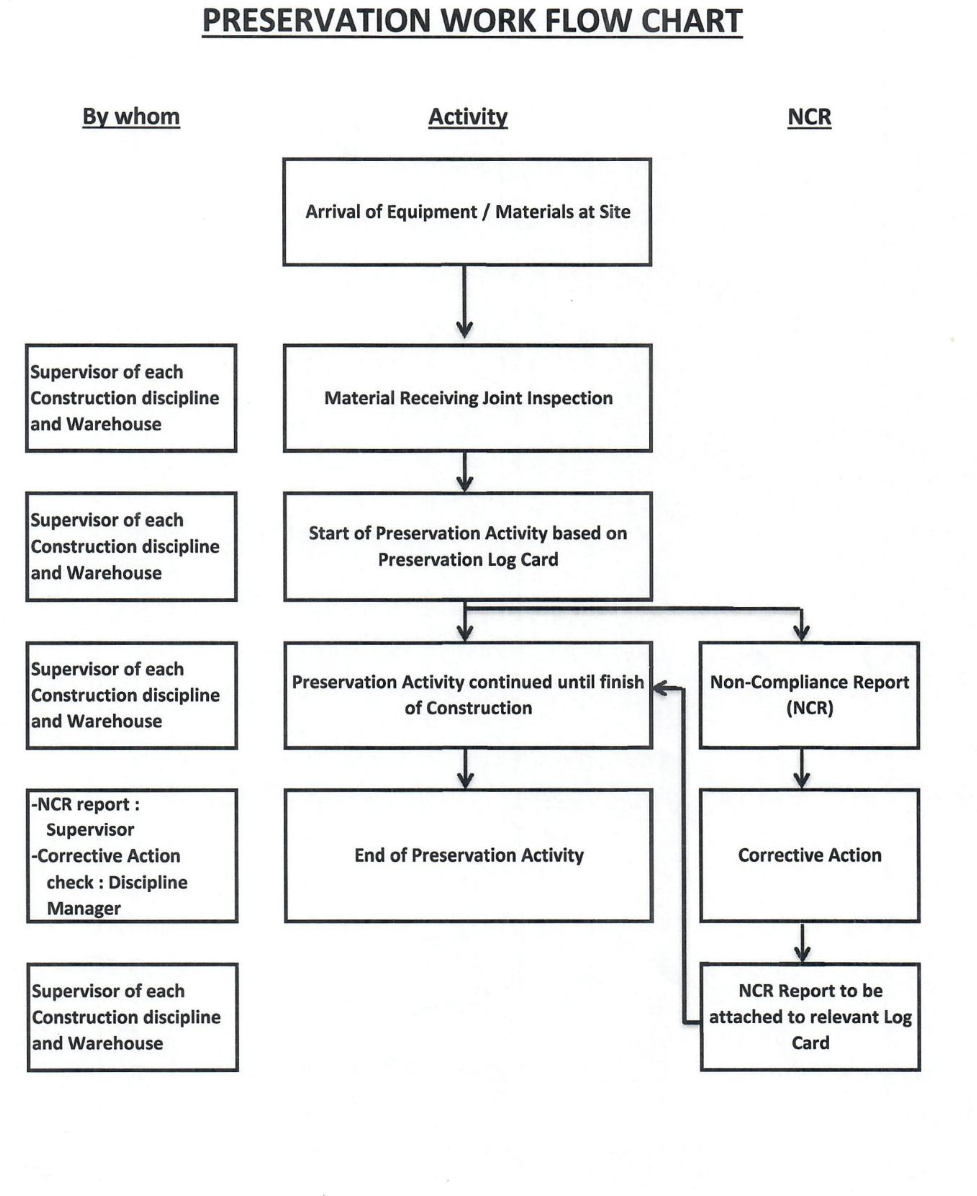

4.4 Preservation Work Flow Chart

Preservation Work Flow chart is attached to this document. Refer to Annex No. 2.

5.0 PRESERVATION MAINTENANCE LOG CARD and NCR

5.1 General

5.1.1 All the preservation activity shall be done basically according to the check points stated on the Log Card.

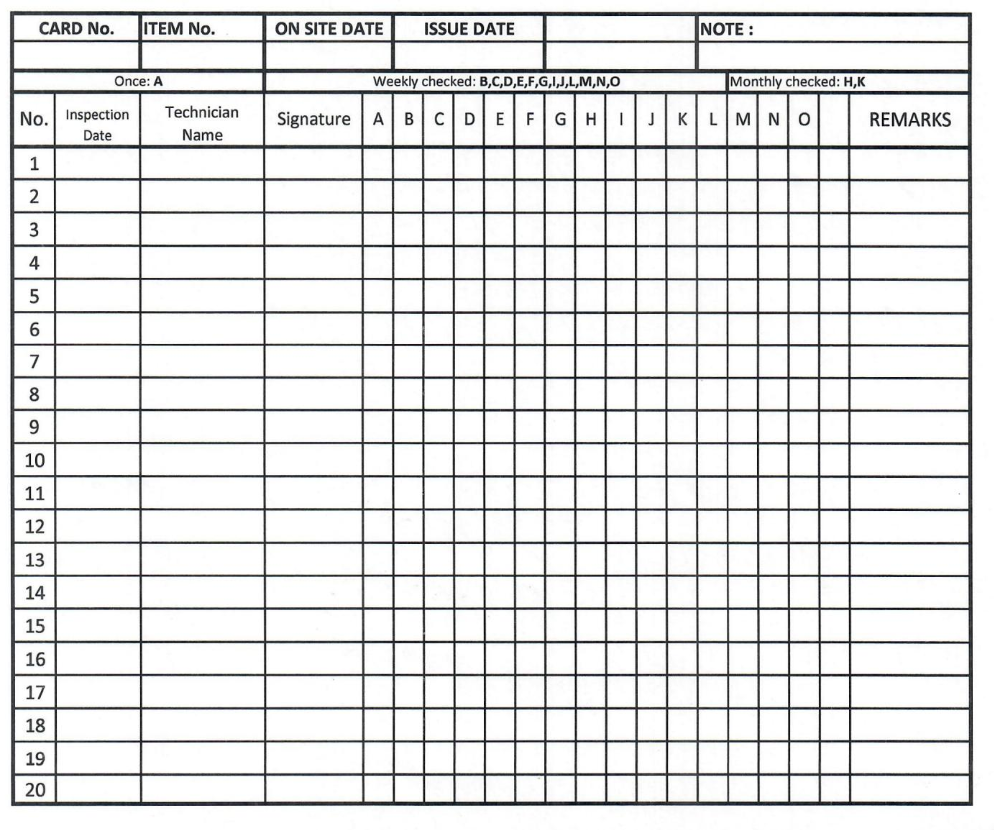

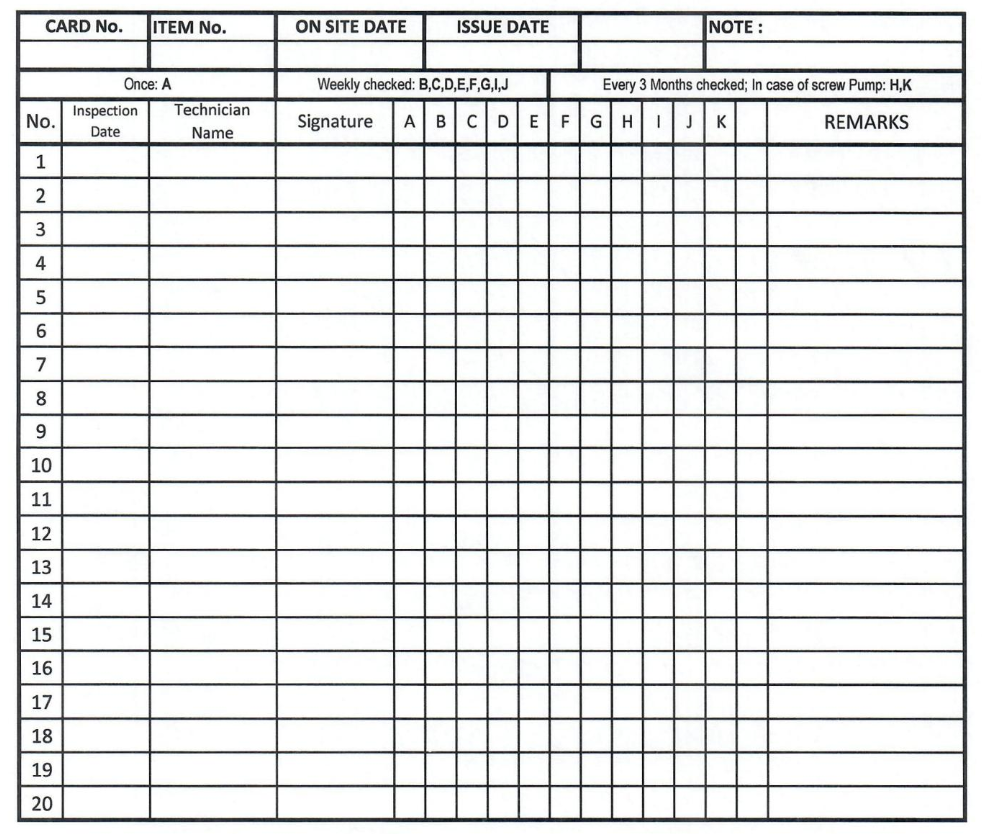

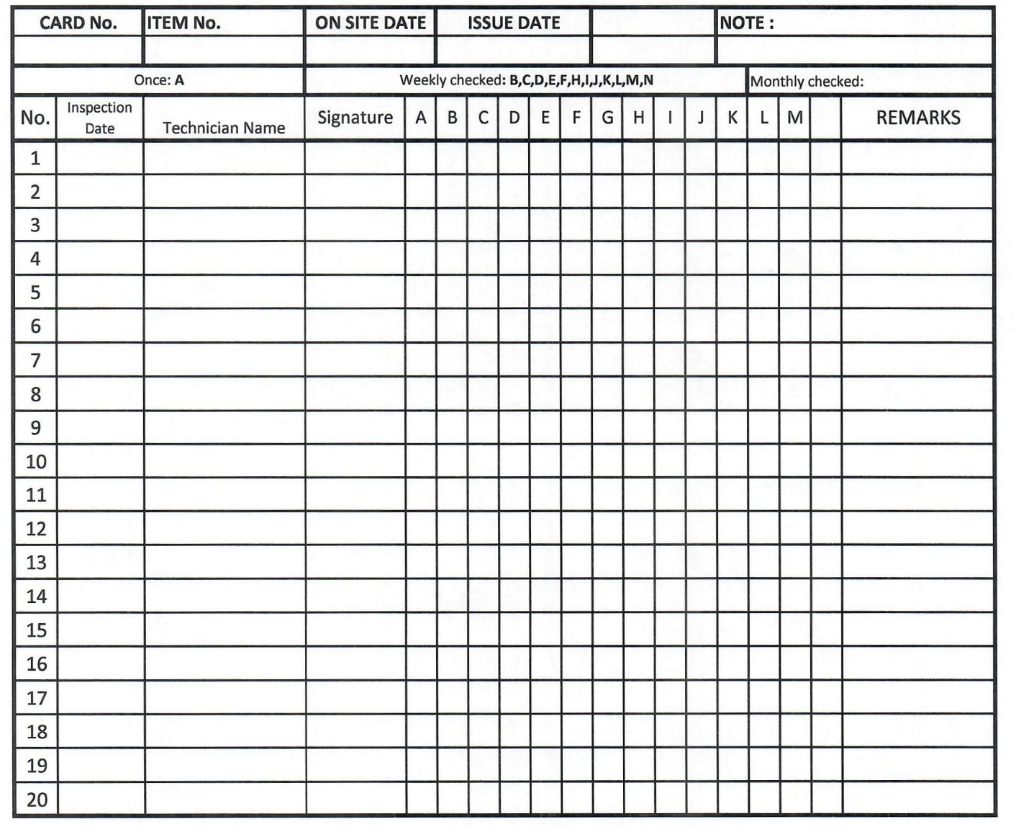

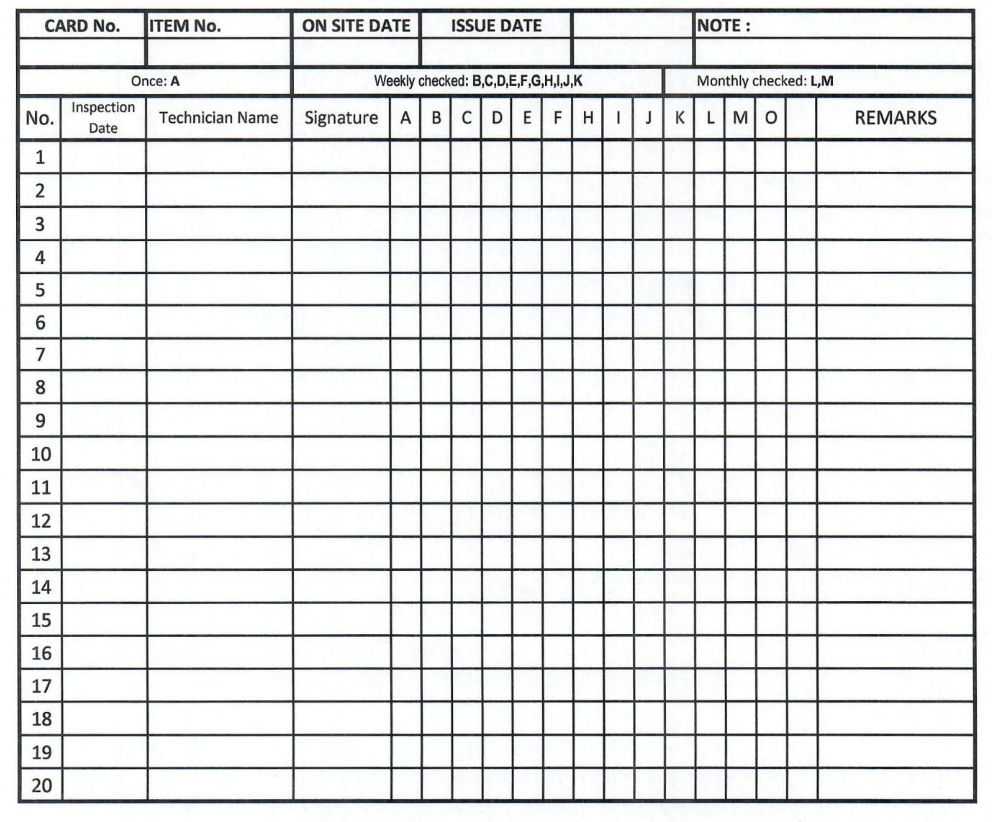

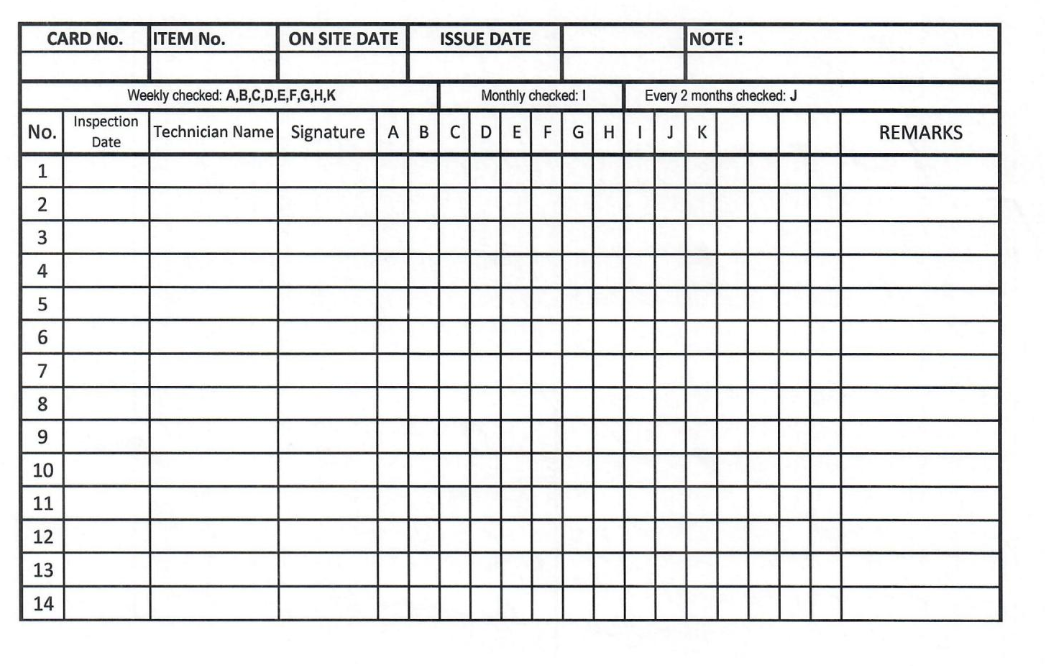

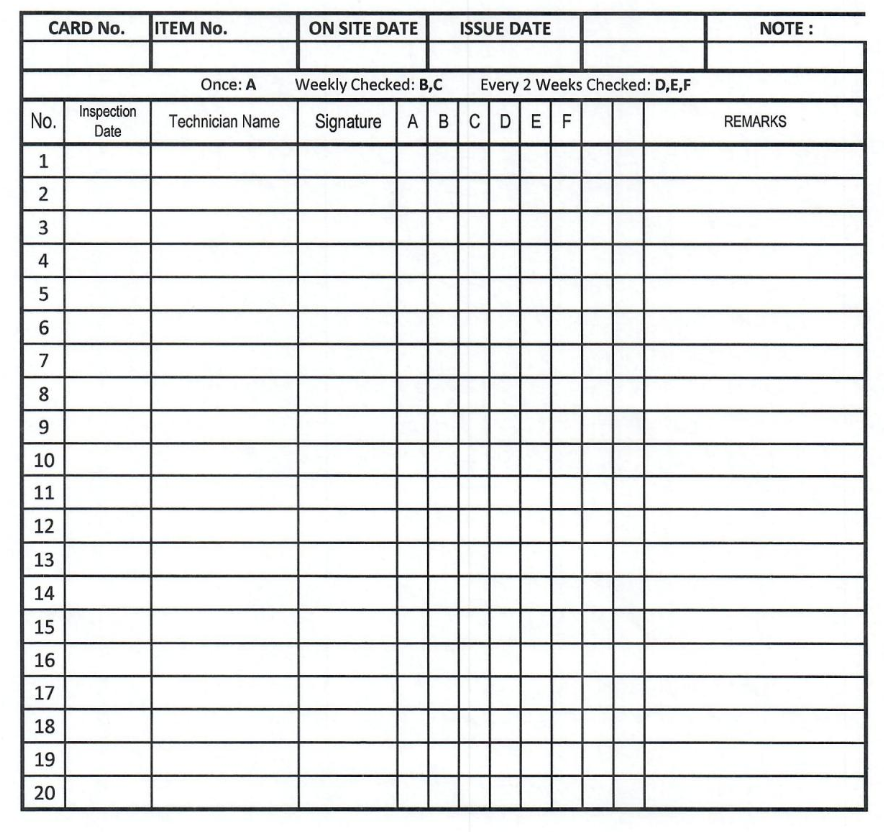

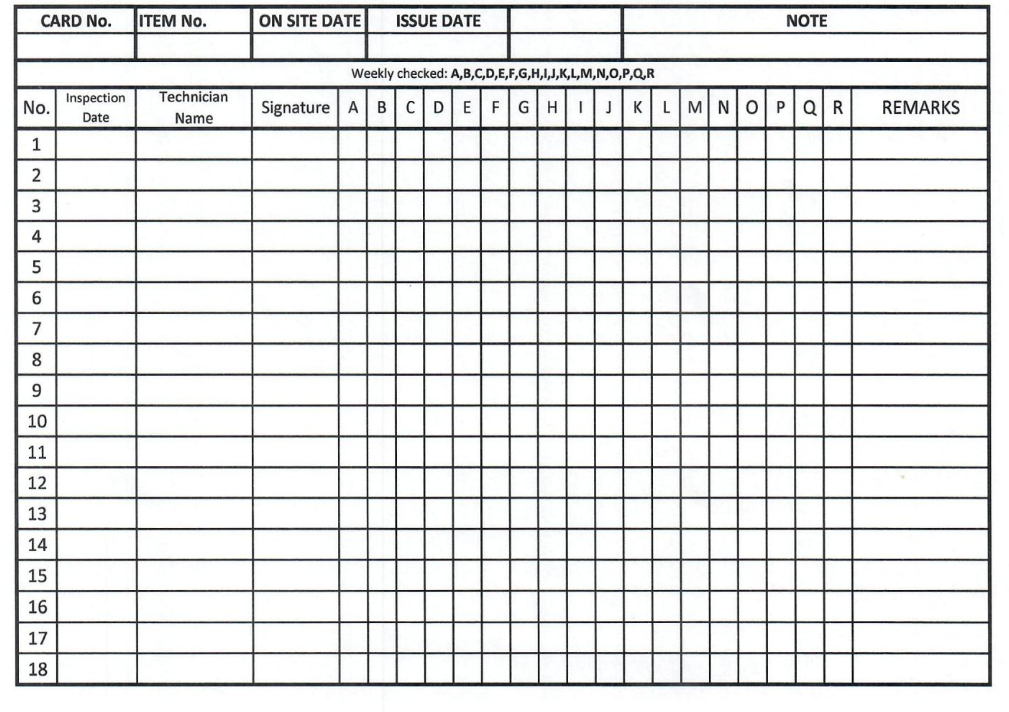

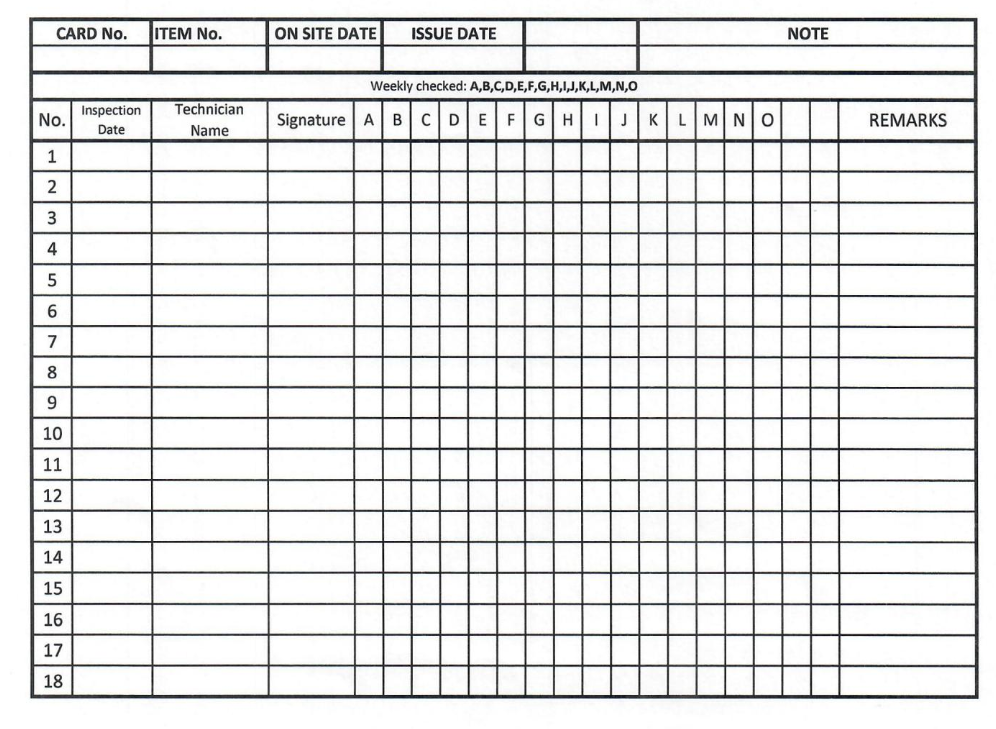

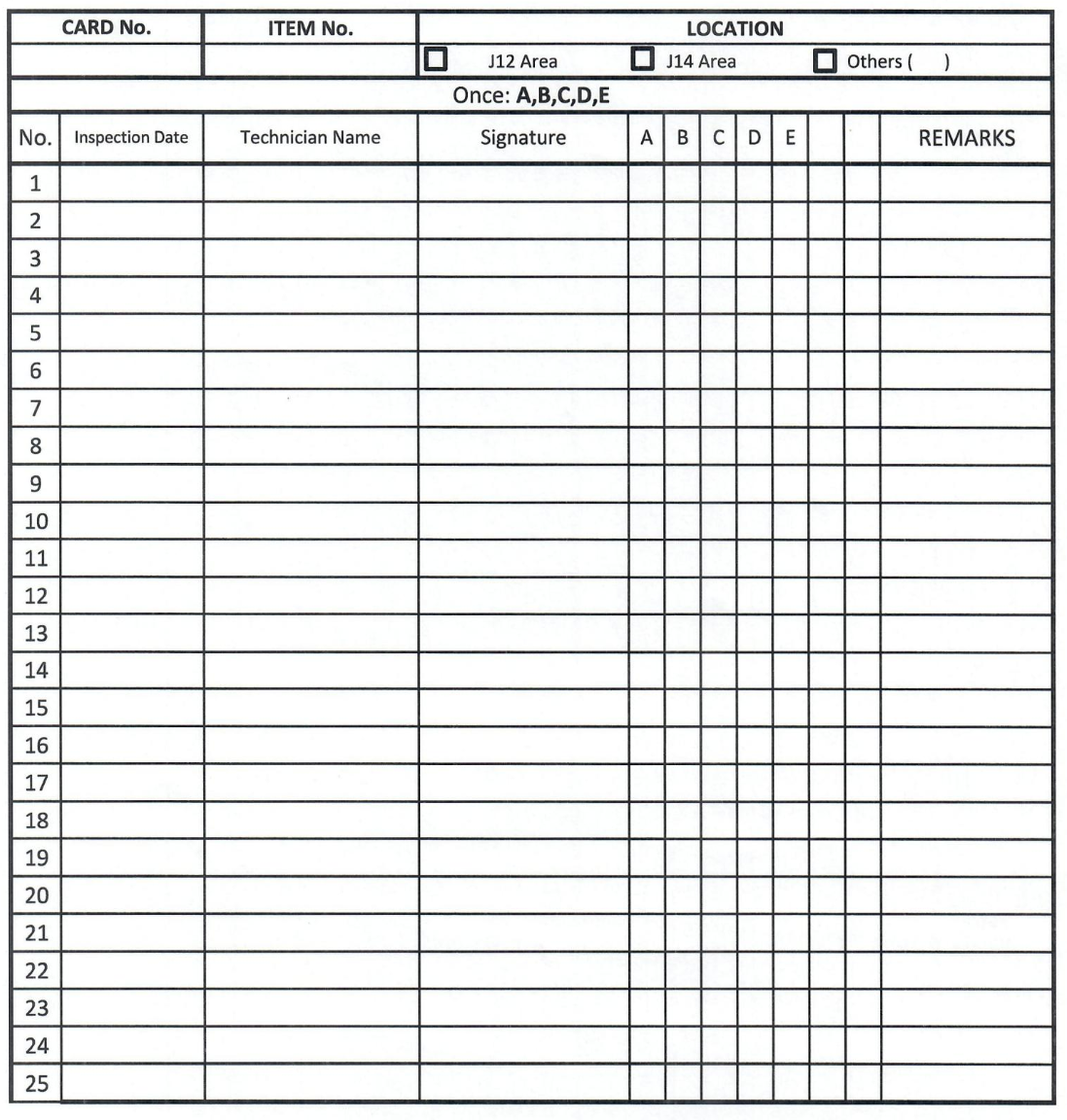

5.1.2 The sample forms of the Preservation Maintenance Log Cards including check points for Static and Rotating Equipment are attached as Annex Nos. 3 ~ 5.

5.1.3 The report of all non-compliance of the preservation conditions including corrective actions have to be attached to the relevant Preservation Maintenance Log Card.

5.2 Explanation of Preservation / Maintenance Log Card

5.2.1 Card Number

This number will be assigned in every Mechanical Equipment upon receiving and installation for identification in the Preservation Maintenance Log Card.

5.2.2 Item Number

This indicates the item or equipment number of the Mechanical Equipment.

5.2.3 On Site Date

This indicates the arrival/installation date of the Mechanical Equipment on site.

5.2.4 Notes

This column can be used for any special remarks.

5.2.5 Check Points

This column shall be ticked if the condition is in compliance with the check point. In case of weekly or monthly checking, the items would be checked accordingly to the Preservation Supervisor’s scheduled plan (ie. in each Monday for weekly records and in each first day of the month for monthly records).

5.2.6 Remarks

This column shall be stated with short observation for any remarkable things.

5.3 Explanation of Preservation Non Compliance Report (NCR)

If the non-compliance of Preservation condition is found and observed as minor and

corrected immediately by the Maintenance Technician upon instructions of the Preservation

Supervisor assigned, the QC Inspector shall be mark the type of non-compliance and to

add “resolved” in the “remark” column of the Preservation Maintenance Log Card.

For major observations, the QC Inspector shall prepare Non-Compliance Report (NCR) and

submit to their Discipline Manager to take corrective action and write the NCR Report No. in

the “remark” column of Preservation Maintenance Log Card.

5.3.1 Non-Compliance Status

This column defines description of non-compliance of preservation conditions.

5.3.2 Corrective Actions

For minor and already fixed non-compliance, the Preservation Supervisor shall

indicate how the non-compliance was resolved: (eg.”The nozzles of J12-G-0620A/B

pumps were covered with plastic film”).

For unresolved non-compliances, the Preservation Supervisor shall indicate

required action/s or make a proposal in order to resolve the non-compliance and

report to their Discipline Manager.

5.3.3 Result

This column defines whether the non-compliance are cleared or not.

6.0 NITROGEN PURGING

6.1 A detailed Method of Statement for Nitrogen Purging shall be submitted for approval prior to

execution.

7.0 QUALITY CONTROL and INSPECTION

A regular weekly series of inspections by related preservation team shall be carried out to audit the state of the preservation and to rectify all non-conformances discovered during surveillance. Likewise, QC Inspectors should perform daily surveillance inspection to ensure quality in field implementation of the equipment preservation and proper actions shall be done if needed and recorded on the log card. Preservation activity can also be checked randomly at site by the PMT/PID at their own discretion.

8.0 SAFETY INSTRUCTIONS AND PRECAUTIONS

8.1 Make sure that all necessary work permits are issued prior to commencement of work.

8.2 Wear minimum PPE and full body harness when working at elevated platform and confined space.

8.3 Ensure that barricades and warning signs are visible and properly installed.

8.4 Check all nitrogen gas hoses and calibrated pressure gauges prior to each use.

8.5 Install adequate illumination when working at dark areas.

8.6 Copy of approved Job Hazard and Risk Assessment (JHRA) to be maintained at work site by Work Supervisor. Conduct daily TSTI and discuss work methodology prior to commencement of work.

8.7 Implement and monitor safety instruction on site.

8.8 Housekeeping shall be maintained and working area shall be kept in a clean and orderly manner before and after work activity.

9.0 ATTACHMENT

9.1 Job Hazard and Risk Assessment (JHRA)

- Preservation Non-Compliance Report

- Preservation Work Flow Chart

- Preservation Maintenance Log Card for Centrifugal Pump

- Preservation Maintenance Log Card for Reciprocating Pump

- Preservation Maintenance Log Card for Centrifugal Compressor

- Preservation Maintenance Log Card for Reciprocating Compressor

- Preservation Maintenance Log Card for Fan

- Preservation Maintenance Log Card for Motor

- Preservation Maintenance Log Card for Fired Heater

- Preservation Maintenance Log Card for Air Fin Fan Cooler

- Preservation Maintenance Log Card for Static Equipment

- Preservation Maintenance Log Card for Before Start Up.

Preservation Non-Compliance Report

PRESERVATION WORK FLOW CHART

PRESERVATION MAINTENANCE LOG CARD (CENTRIFUGAL PUMP)

Field Storage

A. All equipments shall be un-crated and carefully inspected (only once)

B. All equipment shall be stored in designated areas, when equipment stored outdoors, coverings shall be applied & maintained to avoid ingress of moist, sand etc.

C. All rotating equip. mounted on their base plate or skid shall be stored at sufficient level to avoid twist for base plate.

D. All machines stored outdoors shall be stored at higher elevation by wooden sleeper to avoid ingress of water, sand etc.

E. When the rotating equipment is installed, to avoid physical damage cause by crane operation, the machine should be properly protected upon installation and protection shall be maintained.

F. All open flanges faces shall be cleaned with approved solvent and coated with approved rust preventive solution, then replace flange protection (Blind flange, wood plastic cover)

G. Open threaded connections shall be closed with threaded metal or equivalent.

Protection during Construction

H. All external machined surfaces including couplings shall be cleaned and spray coated with approved rust preventive solution. Regular inspections for maintaining and administering the coating (Per month Inspections) shall be done.

I. All nozzle openings shall be protected by blind flange, plug, plastic covers or equavalent. Air breathers, vent connections shall be plugged or sealed air tight with approved suitable compound.

J. Pump internals such as gears, shafts, impeller, casings, etc. shall be prevented from rust by applying an ARAMCO approved compound or solutions.

K. Preservation status of pump internal shall be monitored by checking the blinding of suction/discharge nozzle monthly and take further preservation actions if some defects are found.

L. Breathers on the bearing housing to be replaced by plugs when applicable.

M. Pump shaft to be turned manually once a week. Forced feed lubrication with separate oil reservoir is not applied.

N. For regreasable bearings with provision of nipples, the externals at the nipple shall be cleaned.

O. Coupling to be sprayed/coated with an approved rust preventive oil.

PRESERVATION MAINTENANCE LOG CARD (RECIPROCATING PUMP)

Field Storage

A. All equipments shall be un-crated and carefully inspected (only once)

B. All equipment shall be stored in designated areas, when equipment stored outdoors coverings shall be applied & maintained to avoid ingress of moist, sand etc.

C. All rotating equip. mounted on their base plate or skid shalll be stored at sufficient level to avoid twist for base plate.

D. All machines stored outdoors shall be stored at higher elevation by wooden sleeper to avoid ingress of water, sand etc.

E. When the rotating equipment is installed, to avoid physical damage cause by crane operation, the machine should be properly protected upon installation and protection shall be maintained.

F. All open flanges faces shall be cleaned with approved solvent and coated with approved rust preventive solution, then replace flange protection (Blind flange, wood plastic cover)

G. Open threaded connections shall be closed with threaded metal or equivalent.

Protection during Construction

H. All external machined surfaces including couplings shall be cleaned and spray coated with approved rust preventive solution. Regular inspections for maintaining and administering the coating (Every 3 months), incase of screw pump shall be done.

I. All nozzle openings shall be protected by blind flange, plug, plastic covers or equivalent. Air breathers, vent connections shall be plugged or sealed air tight with suitable compound.

J. Hydraulic chamber and oil-bath type gear box shall be protected by filling with the ARAMCO approved lube oil.

K. Valves shall be removed and stored in warehouse with approved rust preventive solution. Movement of plunger shall be frequently

activated and administered in accordance with suppliers recommendation.

PRESERVATION MAINTENANCE LOG CARD (CENTRIFUGAL OR AXIAL COMPRESSOR)

Field Storage

A. All equipments shall be un-crated and carefully inspected (only once)

B. All equipment shall be stored in designated areas, when equipment stored outdoors coverings shall be applied & maintained to avoid ingress of moist, sand etc.

C. All rotating equip. mounted on their base plate or skid shalll be stored at sufficient level to avoid twist for base plate.

D. All machines stored outdoors shall be stored at higher elevation by wooden sleeper to avoid ingress of water, sand etc.

E. When the rotating equipment is installed, to avoid physical damage cause by crane operation, the machine should be properly protected upon installation and protection shall be maintained.

F. All open flanges faces shall be cleaned with approved solvent and coated with apaproved rust preventive solution, then replace flange protection (Blind flange, wood plastic cover)

G. Open threaded connections shall be closed with threaded metal or equivalent.

Protection during Construction

H. All external machined surfaces including couplings shall be cleaned and spray coated with approved rust preventive solution. Regular

inspections for maintaining and administering the coating shall be done.

I. Couplings shall be sprayed by or coated with approved rust preventive oil solution and stored indoors.

J. Pump internals shall be protected considering the material and the preservation applied by vendor before shipping.

K. Spare rotor to be stored in warehouse as per the manufacturers recommended procedure.

L. Dry gas seals to be stored in an air conditioned environment and shall be installed just prior to start up (if applicable).

M. Couplings shall be sprayed by or coated with approved rust preventive oil solution and stored indoors.

PRESERVATION MAINTENANCE LOG CARD (RECIPROCATING COMPRESSORS)

Field Storage

A. All equipments shall be un-crated and carefully inspected (only once)

B. All equipment shall be stored in designated areas, when equipment stored outdoors coverings shall be applied & maintained to avoid ingress of moist, sand etc.

C. All rotating equip. mounted on their base plate or skid shalll be stored at sufficient level to avoid twist for base plate.

D. All machines stored outdoors shall be stored at higher elevation by wooden sleeper to avoid ingress of water, sand etc.

E. When the rotating equipment is installed, to avoid physical damage cause by crane operation, the machine should be properly protected upon installation and protection shall be maintained.

F. All open flanges faces shall be cleaned with solvent and coated with approved rust preventive solution, then replace flange protection (Blind flange, wood plastic cover)

G. Open threaded connections shall be closed with threaded metal or equivalent.

Protection during Construction

H. All external machined surfaces including couplings shall be cleaned and spray coated with approved rust preventive solution. Regular inspections for maintaining and administering the coating shall be done.

I. All compressor valves and retainers shall be removed and stored in a warehouse after being sprayed with approved rust preventive oil.

J. All internal machined surfaces shall be coated or sprayed with approved rust preventive oil from compressor valve parts and other openings.

K. Inlet/outlet flanges of each cylinder & dampener, frame & distance piece, air breather & vent nozzles shall be covered with metal plates with gasket and adhesive tape.

L. After completion of installation work, including oil flushing of the lube system. The frame of the compressor to be filled with lube oil to normal level and circulated for 30 min by auxiliary lube oil pump biweekly. The crank shaft to be barred or turned several times during oil circulation.

M. Crankshaft shall be turned by weekly so that all the metal portions are covered by oil every month crankshaft to be sprayed with rust preventive oil. Check condition of cross head shoes for rust protection.

PRESERVATION MAINTENANCE LOG CARD (FAN)

Field Storage

A. Fan rotor, coupling, bearings, instrumentations (temperature elements) shall be stored into a clean, dry, well-ventilated, closed place.

B. Fan housing with inlet boxes, bearing bases, shall be stored under not closed shelter.

C. Screws and nuts welded to the housing shall be greased and protected with wood enclosures.

Protection during Construction

D. Coat the shaft and coupling with protective coating.

E. Cover and seal with plastic sheeting the bearing to prevent entrance of contaminants.

F. Cover the drains, pipe connections and conduit with plastic capes or tapes.

G. Cover the opening in the fan housing to keep out dust, dirt and moisture: check that all the doors are closed.

H. Rotate the rotor ten times using the following sequence for final resting position (to assuring that the new shaft position varies from check to

check. Week 1: 360·, Week 2: 90·, Week 3: 180·, Week 4: 270·, etc.

I. Check that the shaft and the machined surfaces are properly protected and no rust is coming evidence (Frequency every month).

J. Check the general status of surfaces and that no rust is coming in evidence (Frequency every two months).

K. For bearings consider the following notes:

1) After fan erection, fill in the supports with oil.

2) If the fan will not function for a long time, put two wedges under the shaft in orderto maintain the supports free from the shaft weight.

3) Every 3 months, turn manually the rotor in order to lubricate the bearing surfaces.

PRESERVATION MAINTENANCE LOG CARD (MOTOR)

Field Storage

A. All equipments shall be un-crated and carefully inspected.

B. All equipment shall be stored in designated areas. When equipment stored outdoors, coverings shall be applied & maintained to avoid ingress of moist, sand etc.

C. Desiccants shall be used inside the terminal boxes and inspected periodically and renewed when it is not active and removed before energizing.

Protection during Construction

D. If anti-condensation healers (space heaters) for motor are provided, they should be energized.

E. When the motor remains installed more than 3 months with the anti-condensation heaters off or no anti-condensation heaters, motor shall be insulation resistance measured according to DEP 63.1D.09.11-Gen and results(lR value) shall be recorded (In Remark column below).

F. All cable entries shall be sealed or plugged and shall be water tight.

PRESERVATION MAINTENANCE LOG CARD (FIRED HEATER)

Field Storage

A. For equipment storage, a storage area shall be dry, self draining and afford access for both cranes and mobile equipment.

B. The equipment shall be checked for transport damage immediately after arrival.

C. Temporary Nozzle covers shall be l)checked regularly to prevent moisture, sand, etc. 2)if covers are missing, to be replaced. 3)protective

coating to be re-applied after metal nozzle cover opened.

D. Check upon arrival N2 pressure and while storage, positive gas pressure is maintained as per vendor’s requirement.

E. Small item to be stored in warehouse location with tag identification.

F. Internal parts storage with tag in accordance with vendor’s instruction.

G. Requirement of desiccant changed to nitrogen pressuring by Discipline Manager.

H. Provide shield to protect vessels when wood support used.

I. Tall tale hose to be filled with grease.

J. Coil and tube ends shall be sealed and bevels protected for field welding.

Protection during Construction

K. The equipment including equipment accessories, foundation, anchor bolts, surrounding structures, underground facilities etc. need to be protected from damage. If there is any possibility of such dammage occuring, proper preventive and protective measures shall be taken according to circumtances involved. (e.g.wood covers, barriers etc.).

L. All manways shall be opened as soon as soon as they are accessible by permanent platforms etc. Flange face shall be verified for damage, cleaned and protected by approved rust preventive compound. If no direct activity is required and manways shall be closed.

M. Equipment under N2 pressure shall be first released prior to open manholes/nozzle. Oxygen shall be measured before handling.

N. Special care to be taken to equipment with sensitive coatings such as refractory, rubber, concrete, epoxy, etc. transportation, erection or when standing idle.

O. Newly installed refractory shall be dried and cured as per manufacture recommendations. Ingress of water into refractory lining shall be prevented.

PRESERVATION MAINTENANCE LOG CARD (AIR FIN FAN COOLER)

Field Storage

A. Temporary nozzle covers shall be checked regularly to prevent moisture, sand, etc.

B. Replace temporary covers if missing.

C. Protective coating to be re-applied after metal nozzle cover opened.

D. Checked upon arrival N2 pressure and while storage, positive gas pressure is maintained as per vendor’s requirement.

E. Small item to be stored in warehouse location with tag identification.

F. Air Fin Cooler lube protection by wooden panels.

G. Internal parts to be stored with tag in accordance with vendors instruction.

H. No moisture retaining materials for SS vessels temp. supports. Provide shield to protect vessels when wood supports used.

I. Tell tale holes to filled with grease.

J. Drive assembly shall be rotated e.g. once a week say one full turn to ensure bearing work properly.

K.Electric motors shall be covered.

L. All nozzle shall be blind flanged and checked for N2 purge before piping hook-up.

Protection during Construction

M. Temporary nozzle covers shall be checked regularly to prevent moisture, sand, etc.

N. All nozzle and manholes shall be opened as soon as they are accessible by permanent platforms, etc.

O. Flange facings shall be verified for damage, cleaned and protected by approved rust preventive compound.

P. In starting internal activities, Flange facing shall be inspected and protected by thin wooden ring plates or equivalent method.

Q. Equipment under N2 pressure shall be first released prior to open manholes/nozzles.

R. Special care shall be taken to equipment with sensitive coating during transportation, erection or when standing idle.

PRESERVATION MAINTENANCE LOG CARD (STATIC EQUIPMENT)

Field Storage

A. Temporary nozzle covers shall be checked regularly to prevent moisture, sand, etc.

B. Replace temporary covers if missing.

C. Protective coating to be re-applied after metal nozzle cover opened.

D. Check upon arrival N2 press and while storage, possitive gas pressure is maintained.

E. Small item to be stored in warehouse location with tag identification.

F. Air Fin cooler fin tube protection by wooden panels.

G. Internal parts storage with tag in accordance to vendor’s instruction.

H. No moisture retaining materials for 55 vessels temporary supports. Provide shield to protect vessels when wood support used.

I. Tell tale holes to be filled with grease.

Protection during Construction

J. Temporary nozzle covers shall be checked regularly to prevent moisture, sand, etc.

K. All nozzles and manholes shall be opened as soon as they are acessible by permanent platforms etc.

L. Flange face shall be verified for damage, cleaned and protected by approved rust preventive compound.

M. In starting internal activities, Flange face shall be inspected and protected by thin wooden ring plates or equivalent method.

N. Equipment under N2 pressure shall be first released prior to open manholes/nozzles.

O. Special care shall be taken to equipment with sensitive coating during transportation, erection or when standing idle.

PRESERVATION MAINTENANCE LOG CARD (BEFORE START UP)

A. Remove preservation elements when required.

B. Replace stuffing box packings in accordance with specification.

C. Drain Lube oil system when required.

D. Refill system with correct specified oil.

E. Assemble equipment when required.