Industry Codes and Standards for IR Testing

NFPA 70 National Electrical Code

NFPA 72 National Fire Alarm Code

UL 44 Thermoset-Insulated Wires and Cables

UL 83 Thermoplastic-Insulated Wires and Cables

TOOLS AND EQUIPMENT FOR IR TESTING

Tools and equipment needed should be in good condition and must be checked by Instrument Supervisor prior to use. These includes but not limited to:

- Fluke or Equal Multi Meter

- Common Hand Tools

- Set of socket wrench

- Screw Drivers

- Cable Tie Fixing Gun

- Cable Numbering Tool

- Heat Gun

- Megger Tester

- Two way Communication Radio

- Test Lead with Test Probe, and Clips

- Insulation Electrical Tape

PROCEDURE FOR CONTINUITY AND INSULATION RESISTANCE TESTING

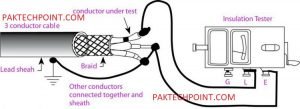

- Perform Megger Test on each cable with respect to ground and adjacent cables. For cables 300 volt use 500 VDC megger; for cables above 300 volt to 600 volt use 1000 volt megger; for cables above and less than 1200 volt use 2500 volt megger

- Perform insulation-resistance test on each conductor with respect to ground and adjacent conductors. Applied potential shall be 500 volts dc for 300 volt rated cable and 1000 volts dc for 600 volt rated cable. Test duration shall be one minute. [NETA ATS Sec. 7.3.2.2.2 – 2009]. The results shall be recorded and shall be greater than 50 mega ohms.

- The insulation resistance between cores shall be checked. The insulation resistance between conductor to screen and to armor shall be checked. The insulation between overall drain and armor shall be checked.

- Capacitance should be discharged, both before and after an insulation resistance test.

- Perform continuity test to ensure proper cable connection.

- Equipment Voltage Rating Recommended Test Voltage

300 500

300 – 600 1000

600 – 1200 2500