ThiThis article is about SF6 Circuit Breaker Material Selection and Design Notes of MV Switchgear in Commercial buildings, plants and refineries.

F6 Circuit Breaker Material Selection and Design Notes

- The bus maybe contained within an SF6 insulted compartment or be insulated with a solid insulating material. Tape insulation of bus and or bus joints is unacceptable. The switchgear cable terminations are designed for use with fully-shielded, dead-front, separable cable connectors.

- The pad-mounted switchgear assembly shall be for outdoor application, and shall be designed for mounting on a precast concrete pad/foundation.

The pad-mounted switchgear shall be suitable for use in locations that are subject to sand and dust storms, fog, and airborne contaminants, including NaCl (Sodium Chloride) to 300 ppm and MgCl (Magnesium Chloride) to 50 ppm.

- The pad-mounted switchgear shall be suitable for use in locations with the following ambient temperatures: Average monthly normal maximum (hottest month), 45°C; Average daily temperature (hottest month), 40°C; Maximum daily peak 50°C.

- All documentation shall be in the English language.

- The switchgear supplied under this specification shall be furnished with appropriate bushings suitable for use with fully-shielded, dead-front, non-load-break, 600 amp minimum separable connectors. Bushings must be supplied with removable fixing studs, with SAE 5/8-11 UNC threads for fastening the connector in position. (SAE-Society of Automotive Engineers; UNC-Unified National Coarse).

- Space shall be provided within the enclosure/cable covers for the termination of two cables per phase on the loop feed switches. All cables shall be horizontally isolatable.

- The switchgear assembly shall have a specifically designed pressure-relief feature. It shall not rely on fortuitous relief by burn-through or overpressure induced failure of the basic switchgear structure.

- Tests to establish internal arc performance shall be performed at, or endorsed by, an independent laboratory in general compliance with the internal arcing criteria of IEC 62271-Annex AA.

- Vent ducting is required to direct internal arc products from the switchgear tank(s) through the rear, side wall, or bottom of the outer, weatherproof enclosure.

For grounding purposes, a minimum 6 mm x 50 mm copper ground bus shall be provided which runs the full length of the switchgear assembly, suitably positioned to allow grounding of the switchgear frame and cable shields. The ground bus shall be bonded to the base frame. Provisions shall be made on the ground bus for connecting cable shields and armors, grounding conductors, and ground rods.

- Operating handles shall be provided and be located in a proper storage mounting arrangement. The operating mechanism shall be pad-lockable in the OFF and GROUND positions.

- Each Way shall be provided with three (3) positions: ON-OFF-GROUND. The “ON” and “GROUND” positions shall be rated for momentary (close & latch) and short time current withstand. The switch mechanism shall be constructed in such a way that only one action at a time can be taken, so that switching from “ON” directly to “GROUND” will be prevented. Switching shall be from “ON” to “OFF” then from “OFF” to “GROUND”. Separate interlocked switches and selectors may be provided to meet the above requirements.

The circuit breaker, load-break and ground switch functions shall be stored-energy, spring-operated, to provide fast and reliable operation. The speed of operation of the switch shall be independent of the operator. When a separate selector is provided the switching device must be mechanically interlocked so that it can only be operated (Closed) when the selector is in a determinate position (ON/OFF/Ready to Earth).

- Springs and moving parts of the switch operating mechanism(s) shall be located inside the weatherproof enclosure protected from environmental conditions.

- Viewing windows and/or indicators positively driven by direct linkage, clearly delineating the “CLOSED”, “OPEN” and “GROUND” positions are required.

- A permanent mimic bus diagram shall be provided to represent the equipment single-line configuration. This shall be mounted on the operating face of the equipment.

- Low voltage wiring shall be ANSI/NFPA 70; Type SIS, XHHW or THHN/THWN or 85° rated meeting the requirements of IEC 60227.

- Cable potential detection system shall be provided.

The enclosures for outdoor use shall be NEMA ICS 6 Type 3 or IEC 60529 Type IP54, fabricated from a minimum of 2 mm (14 gage) sheet steel. The enclosure door(s) shall be provided with pad-lockable handles.

Commentary Note:

This enclosure shall be used for the protection of switchgear not inherently designed for use outdoor which includes equipment intended for subsurface use.

- The base frame of the enclosure shall be made of hot-dipped galvanized steel. The switchgear shall be fixed to this base. The assembly shall be adequately braced to provide strength and rigidity under normal operating conditions and during transportation.

- Bolts, hinges, and associated hardware shall be Type 300 Series stainless steel. Gasketing materials and adhesives shall be suitable for the environmental conditions.

- The enclosure/switchgear assembly shall be suitable for mounting on a concrete pad or foundation by means of anchor bolts.

The enclosure assembly structure shall be provided with adequate lifting or jacking means and shall be capable of being lifted or slid into position.

- All exterior and interior surfaces of the equipment shall be painted and shall meet the requirements of ANSI/IEEE C57.12.28 -Pad Mounted Equipment-Enclosure Integrity, Section 5 -Enclosure Coating System, except the paint color shall be white, or light gray unless otherwise specified. A wet paint process is described in the paint system requirements of ANSI/IEEE C57.12.28. However, an equivalent coating system utilizing an electrostatic powder coating process is acceptable.

The weatherproof enclosure shall be suitable for severe corrosive environment locations as noted below when specified in the Data Schedule and shall be manufactured of 300 series stainless steel.

Commentary Note:

The following locations are deemed as “severe corrosive environments” for the purposes of selection of electrical equipment:

• Outdoor offshore locations

• Outdoor onshore locations within one kilometer from the shoreline of the Arabian Gulf

• Outdoor onshore locations within three kilometers from the shoreline of the Red Sea.

• All of the Ras Tanura Refinery and Terminal.

- A nameplate shall be permanently attached on the front of the switchgear assembly, not the inside of the weatherproof enclosure.

- The nameplates shall be stainless steel and attached with stainless steel hardware. Entries shall be marked by etching, engraving or other permanent marking method.

- The nameplates shall be in the English language according to American usage.

- Danger and warning labels shall be written in both Arabic and English, utilizing white characters on a red background. If specifically noted Arabic warning indicators will be supplied by others.

In addition to the standard switchgear data the nameplate information shall include the following, which may be on a separate plate:

a) Buyer’s Purchase Order number

b) Manufacturer’s location

c) Manufacturer’s order reference number

d) Equipment Serial Number

e) Date of Manufacture

Switching Device Variations

Switching Devices as specified in the DATA SCHEDULE shall include the option of:

• Load-break Switches, and/or;

• Circuit Breakers (including control and protection equipment).

Load-break Switches

Load-break switches shall comply with the requirements of this specification as described in Sections 7 and 8 above.

- Circuit breakers shall be provided in combination with three (3) position disconnect switch as specified in Sections 7 and 8 above.

For Industrial Use:

A set of three phase and ground current transformers shall be provided. The class of CT shall be selected to avoid CT saturation at the maximum fault rating of the system for phase CT’s. The zero sequence ground CT shall be C20 or the IEC equivalent for equipment manufactured to IEC standards.

- A three phase and ground fault relay as per 16-SAMSS-513 shall be mounted remotely or on the switchgear, as indicated in the data sheet.

- A 125 V dc shunt trip coil shall be provided.

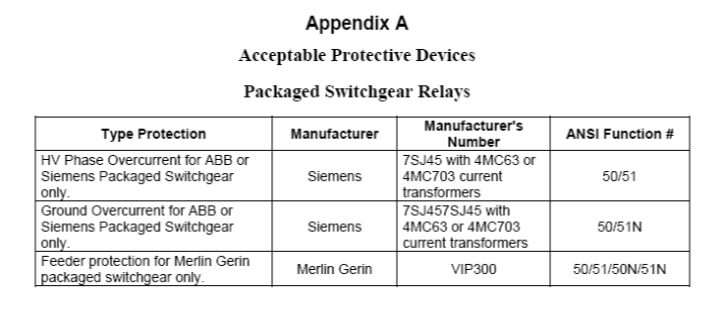

- (See Attachment 1) A solid-state protection package shall be as specified in Appendix A or equipment manufacture’s equivalent. This protection package shall be suitable for service in environmental conditions as described in Section5. The protection shall be self-powered from the current provided by the protection Current Transformers (CT’s).

- When specified in the Data Schedule cable fault detectors shall be provided for loop feed applications. As a minimum, two (2) sets shall be supplied, each set shall comprise two (2) short circuit elements and one (1) ground fault element together with all necessary controls and indication (NORTROLLCABLETROLL 2000 or equivalent). Cable fault detection shall be indicated by red color LEDs.

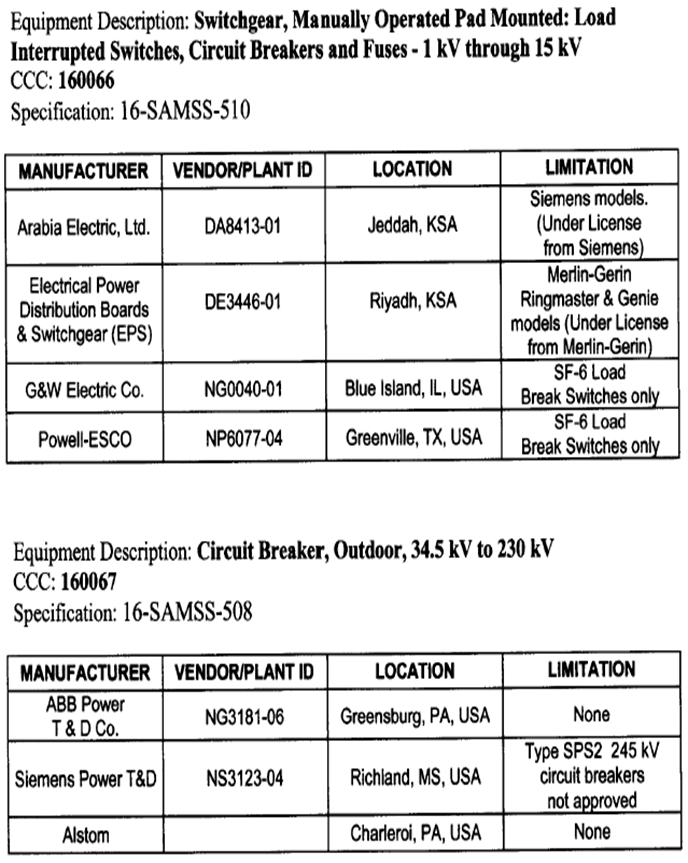

SF6 Circuit Breaker International Codes and Standards for MV Switchgear

| 16-SAMSS-510 Manually Operated Pad Mounted SF6 Switchgear: 1 KV to 36 KV |

| SAES-P-101 Regulated Vendors List for Electrical Equipment |