This article is about Stainless Steel and Copper Tubing Selection Criteria and Installation & Requirements of Instrumentation and Control Systems as per International Codes and standards for Commercial Buildings, Plants and Refinery Projects.

Stainless Steel and Copper Tubing Selection Criteria and Installation

Material Receiving General Checklist for Instrumentation & Control

Copper Tubing – Material requirements – IP01A (Based on material, temperature and usage, refer the appropriate sec of PIP PCSIP001)

“Design Pressure and Temperature Ratings: The tubing system components specified in the material specification of the project are to confirmed with that of the material manufacturer data for the following conditions: [PIP PCSIP 001 Sec 4.1.1 ]

“Tubing Dimensions:

• 1/4-inch outside diameter (OD) + 0.003-inch, 0.030-inch wall

• 3/8-inch OD + 0.003-inch, 0.032-inch wall

• 1/2-inch OD + 0.003-inch, 0.035-inch wall

[PIP PCSIP 001 Sec 4.1.2.2 ]”

“Tubing Material:

Seamless per ASTM B68 or ASTM B75, Copper Alloy Number No. C12200, 060 temper (soft anneal), Rockwell 15T hardness 60 maximum. [PIP PCSIP 001 Sec 4.1.2.1]”

“Tube Fittings: Brass, flareless compression type. The fitting nomenclature shall be in accordance with ISA RP 42.1.

[PIP PCSIP 001 Sec 4.1.3]”

Globe/Needle Valves: Tubing Valves – Brass body 1/4-inch, 3/8-inch, and 1/2-inch tubing connections, polyfluorethylene (PTFE) packing, rated 300 psi at 250°F. [PIP PCSIP 001 Sec 4.1.4.1]

“Screwed Valves – Brass body to be 1/4-inch, 3/8-inch, and 1/2-inch female NPT connections, PTFE packing, rated 300 psi at 250°F.

[ PIP PCSIP 001 Sec 4.1.4.2 ]”

Ball Valves: Tubing Valves – Brass body, 1/4-inch, 3/8-inch, and 1/2-inch tubing connections, PTFE packing, trip-proof handle, rated 300 psi at 250°F . [PIP PCSIP 001 Sec 4.1.5.1]

“Screwed Valves – Brass body, 1/4-inch, 3/8-inch, and 1/2-inch female NPT connections, PTFE packing, trip-proof handle,

rated 300 psi at 250°F. [PIP PCSIP 001 Sec 4.1.5.2]”

Check Valves: Tubing Valves – Brass body, 1/4-inch, 3/8-inch, and 1/2-inch tubing connections, rated 1105 psi at 350°F, PTFE O-ring, 1-psi cracking pressure. [PIP PCSIP 001 Sec 4.1.6.1]

Screwed Valves – Brass body, 1/4-inch, 3/8-inch, and 1/2-inch female NPT connections, rated 1105 psi at 350°F, PTFE O-ring, 1-psi cracking pressure. [PIP PCSIP 001 Sec 4.1.6.2]

Pipe Fittings and Nipples: Brass screwed fittings, couplings, and unions per ASME B31.3 and ASTM B453. Sizes 1/4-inch, 3/8-inch, and 1/2-inch. All NPT threads are to meet requirements of ANSI B1.20.1. All nipples are brass, to be extra strong, temper reference 061. [PIP PCSIP 001 Sec 4.1.7]

Thread Sealant/Lubricant: White-thickened PTFE dispersion, no metallic fillers, certified nontoxic. [ PIP PCSIP 001 Sec 4.1.8 ]

Stainless Steel Tubing – Material Requirements IP-12P Type

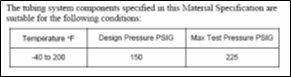

Design Pressure and Temperature Ratings: The tubing system components specified in this Material Specification are suitable for the following conditions: [PIP PCSIP 001 Sec 4.4.1]

“Tubing Material:

Seamless or welded per ASTM A269, Type 304 UNS S30400, fully annealed austenitic stainless steel, hardness Rockwell B80 maximum. [PIP PCSIP 001 Sec 4.4.2.1]”

“Tubing Dimensions:

• 1/4-inch OD + 0.005-inch, 0.035-inch wall

• 3/8-inch OD + 0.005-inch, 0.035-inch wall

• 1/2-inch OD + 0.005-inch, 0.035-inch wall

[PIP PCSIP 001 Sec 4.4.2.2]”

Surface finish shall be free of any imperfections that would prevent sealing when using flare less compression-type tube fittings. [PIP PCSIP 001 Sec 4.4.2.3]

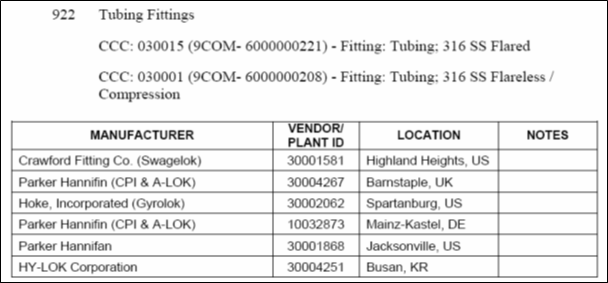

“Tube Fittings: Type 316 stainless steel, flare less compression type Fitting nomenclature shall be in accordance with ISA RP 42.1.

[PIP PCSIP 001 Sec 4.4.3 ]”

Pipe Fittings and Nipples: Type 304 stainless steel 3000# forged alloy screwed fittings, couplings, and unions per ASME B31.3 and ASTM A182. Sizes 1/4-inch, 3/8-inch, and 1/2-inch. All NPT threads are to meet requirements of ANSI B1.20.1. All nipples are 304 stainless steel, schedule 80 minimum. [PIP PCSIP 001 Sec 4.4.7]

Thread Sealant/Lubricant: White-thickened PTFE dispersion, no metallic fillers, certified nontoxic. [PIP PCSIP 001 Sec 4.4.8]

Instrument Air Piping and Tubing Material

Materials for instrument air tubing shall be chosen with full consideration of requirements for the application, such as external corrosion resistance, vibration resistance, and fire protection. [PIP PCCIP 001 Sec 4.3.1]

“For single-instrument air supply tubing, the minimum shall be copper, 3/8-inch outside diameter (OD) x 0.032-inch wall.

[PIP PCCIP 001 Sec 4.3.2]”

For pneumatic signal tubing, the minimum shall be copper 1/4-inch OD x 0.030-inch wall. [PIP PCCIP 001 Sec 4.3.3]

“Stainless steel tubing shall be used near high-vibration equipment and where required by process or ambient conditions.

Comment: Polyethylene tubing may be used, with owner approval, in applications in which it is desirable to have a valve fail to a specific position based on loss of air from the tube melting in a fire.

Comment: Stainless steel tubing may be used on preassembled equipment, such as control valves.

[PIP PCCIP 001 Sec 4.3.4]”

Process Instrument Tubing and Piping Materials

- Instrument Piping: From the primary block valve to the instrument, the instrument piping specifications shall be used. The materials of construction and pressure ratings of all process-connected instrument piping, fittings, and valves shall be compatible with and meet or exceed applicable piping specifications for the process service. [PIP PCCIP 001 Sec 5.2]

Instrument Tubing: From the primary block valve to the instrument, all process-connected instrument tubing shall be compatible with applicable piping specifications for the process service, subject to the minimum requirements listed below (F3 & F4). [PIP PCCIP 001 Sec 5.3.1]

Instrument process tubing, as a minimum, shall be Type 316 stainless steel 3/8-inch OD x 0.035-inch wall tubing. Fittings shall be, as a minimum, Type 316 stainless steel. [PIP PCCIP 001 Sec 5.3.2]

Tubing and associated components shall conform to the applicable material specifications in PIP PCSIP001. [PIP PCSIP 001 Sec 5.3.3]

Traced and Insulated Tube Bundles: When heat tracing is required, prefabricated traced and insulated tube bundles are preferred. When short leads or configuration prevent reasonable use of these bundles, individual tubes with field-installed tracing and insulation shall be provided. [PIP PCCIP 001 Sec 5.4.1]

International Standard and Codes for Stainless Steel and Copper Tubing

Copper Tubing, Brass Fittings, and Valves for Instrument Service

3. SAES-J-002 – Regulated Vendor List for Instruments, 23 June 2008

4. SAES-J-100 – Process Flow Metering , 5 April 2008

5. PIP PCSIP001 – Instrument Piping and Tubing Systems Specifications – Oct. 2002

6. PIP PCCIP001 – Instrument Piping and Tubing Systems Criteria – Oct. 2002

7. O Brien Tracepak Instructions. http://www.obcorp.com/WebPages/literatu.html

1. Attachment 1: Approved Vendor list SAES-J-002