This article is about STRUCTURAL STEEL PROCEDURE and focusing to the engineers, technicians and supervisors. You will find lot of documents related to this article. Just navigate our website www.paktechpoint.com and find more articles. Please! Do not forget to subscribe our You tube channel also. Thanks in Advance.

PLEASE SUBSCRIBE OUR PAKTECHPOINT YOUTUBE CHANNEL

STRUCTURAL STEEL PROCEDURE

Verify Interface Structures

– Prior to structural steel being erected, verify that all interface work such as foundation elevations, and size and location of anchor bolts conform to the applicable drawings. Verify that concrete has attained adequate compressive strength before loading.

Erection of Structural Steel

– Structural steel shall be erected in accordance with the applicable project specifications.

– Assure structures are not loaded prior to sufficient progression of erection and completed boltup has been accepted.

– Welding shall be performed by AWS (or other approved recognized standards) qualified welders in accordance with weld procedure specifications approved by JAL Manager Welding Technology or his representative.

– Modifications to steel member shall only take place upon issuance of direction from Construction Engineering.

In-Process Inspection of Structural Steel Erection

– Inspect the in-process steel erection to verify that fabrication is correct and erection is in accordance with the drawings. Inspection shall include checking for plumbness, rectangularity, field welds, bolt tensioning and touch-up painting.

– Visual weld examination shall be performed in accordance with below form, Welding Inspection.

[docxpresso file=”https://paktechpoint.com/wp-content/uploads/2018/08/Q4.TSMD_.266.odt” comments=”true” SVG=”true”]

– Document inspections on Form Structural Steel Inspection Checklist. Highlighted steel erection drawings may be used in conjunction with checklist to provide a clear picture of sequence of events with dates of when areas, floors, and buildings have been accepted for workmanship.

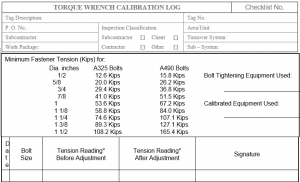

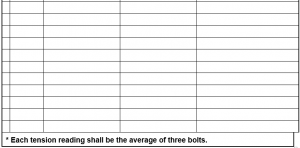

– When a calibrated impact wrench is used for erection, the calibration shall be verify by the Civil Construction Engineer or QC Inspector and documented on Torque Wrench Calibration Log.

- When bolting inspection by impact is required, it shall be performed with a separate calibrated inspection wrench.

- When “twist-off” type tension control structural bolt/nut/washer assemblies are specified they shall conform to ASTM F1852-98 and shall be, installed in accordance with the manufacturer’’ published specifications.

– When load indicating washers (LIW) are specified, installation inspection will be performed in accordance with the sample rate specified.

– Inspect bolts installed by turn-of-nut method in accordance with AISC Section 6, Specification or other approved recognized standard for Structural Joints using ASTM A325 or A490 bolts.

– The number of checklist completed should be a sufficient number to clearly indicate full coverage of all portions of the work on the project as work progresses.

– Each checklist generated should represent a well defined piece of work, i.e., building line, floor, run of pipe rack, etc.

- Perform Final Inspection:

Structural Steel Inspection Checklist

Torque Wrench Calibration Log

I believe that is among the such a lot significant information for me. And i am glad reading your article. But should remark on few normal things, The site taste is perfect, the articles is truly great : D. Good process, cheers