Transducers and Instrumentation for Vibration Measurement and Monitoring of Rolling Element Bearings

1. REBAM Instrumentation System

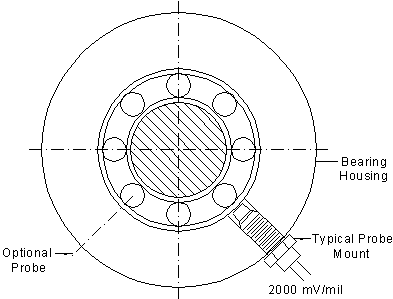

Rolling Element Bearing Activity Monitor. The REBAM system uses a high-gain, low-noise eddy current proximity transducer that is installed in the bearing housing observing the bearing outer ring.

The bearing outer ring contains the outer race. The REBAM® transducer measures the very small (microinch/micrometre) deflection of the outer ring as the rolling elements pass the area observed by the transducer. These deflections are measured in terms of displacement. The operating frequency range for the REBAM® transducer system is from 0 Hz (dc) to 10 kHz (0 to 600 kcpm). The REBAM® system is a direct and very sensitive method of rolling element bearing measurement. It offers a very high signal-to-noise ratio, as compared to casing-mounted acceleration or velocity measurements.

Through the use of electronic filters, the REBAM® vibration signal is separated into Rotor Vibration and Prime Spike regions as previously discussed. Typical Prime Spike amplitudes are 10 to 50 microinches (0.25 to 1.3 micrometres) for a good bearing and 2 to 5 times that for a damaged bear-ing. However, the amplitude of the REBAM® signal is highly dependent upon the amount of loading on the elements as they pass the location of the probe, and it is, therefore, not possible to give broad guidelines for a healthy or a damaged bearing. A common practice is to take readings on what is known to be a healthy bearing and set the monitor Alert and Danger alarm levels at 1.5 and 2 times the baseline level. Field and lab tests confirm that using such alarm levels provides adequate failure protection.

2. Casing Vibration Instrument Systems

Rolling element bearing condition can be monitored by using casing measurements. Overall velocity or displacement, Prime Spike velocity, and the high frequency acceleration regions can be used. Bently Nevada can provide accelerometer or velocity transducer-based systems to monitor rolling element bearing condition. Overall casing velocity or displacement provides a means for determining the general mechanical condition of rolling element bearing machinery.

For a velocity transducer-based system, the frequency range used is from 10 Hz to 1 kHz (600 cpm to 60 kcpm). For an accelerometer-based system, the frequency range used is from 10 Hz to 20 kHz (600 cpm to 1.2 million cpm). Depending on the machine speed, the velocity system frequency range is likely to span the Rotor frequency region and the lower end of the Prime Spike frequency region. The acceleration system will cover the Rotor frequency region, Prime Spike region, and into the high frequency region.

As stated previously, the Prime Spike region is used by Bently Nevada to monitor the rolling element bearing-related frequencies (inner/outer race defects). By filtering out the rotor-related vibration signals (i.e., 1X, 2X, etc.), it is possible to get better signals related to the rolling element bearing condition. The Prime Spike frequency region includes thefundamental element passage frequency (EPx) and harmonics up to 7 EPx.

If an accelerometer-based system is used, Prime Spike and high frequency measurements are available. However, due to the noise susceptibility problems previously mentioned, the high frequency measurements should be used only as a possible early indicator of impending rolling element bearing problems. The high frequency range used by Bently Nevada is from 5 kHz to 25 kHz (300 kcpm to 1500 kcpm). High frequency measurements are useful when diagnosing certain machine malfunctions previously mentioned.

The following alarm threshold guidelines were established for the three diagnostic techniques based on field tests conducted by Bently Nevada:

1. Overall velocity: 0.3 in./sec. (7.7 mm/s) pk.

2. Prime Spike region: 0.1 to 0.15 in./sec. (2.5 to 3.8 mm/s) pk.

3. High frequency region: 3 to 4 g pk.

Note: These alarm threshold levels for balance-of-plant equipment should be considered as an initial guide only. The levels may need adjusting up or down, depending on how an individual monitored machine behaves.

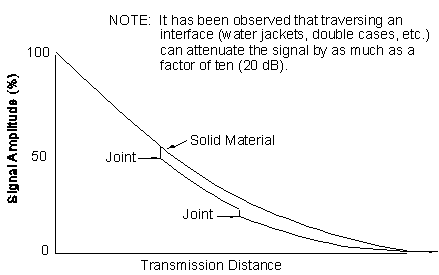

When using casing measurement systems, two key factors should be considered: (1) signal amplitude versus transmission distance and (2) the measurement’s susceptibility to noise. The farther away a vibration measurement is made from the vibration source, the more the signal will be attenuated. Most rolling element bearing machines have joints between machine parts which further attenuates the signals. Figure shows that there is a sharp vibration signal attenuation at each joint.

The closer the measurement is made to the machine vibration source, the better the measurement. For a rolling element bearing, it is suggested to be within 1 to 2 inches (25 to 50 mm) from the bearing. Another fact that must be considered is a comparison of the various transducer systems’ signal-to-noise ratios. System signal-to-noise ratio is defined as the ratio of the amplitude of a desired signal at any point to the amplitude of noise signals at that same point. A comparison of the signal-to-noise ratios for the various transducer systems is shown in figure.

If not carefully considered, these two factors can have a large negative impact on the success of using casing measurements for monitoring.

Summary

Based on the Bently Nevada two part philosophy of (1) providing adequate warning to avert machine failures and (2) removing bearings only when they are likely to have visible evidence of an impending failure, the following conclusions are drawn:

1. Rotor vibration and Prime Spike displacement (obtained from permanently-installed REBAM® probes) or overall velocity and Prime Spike velocity (obtained from a casing-based measurement), are the primary techniques used to monitor rolling element bearings. These measurements should be used to determine when to remove the bearing.

2. High frequency measurements are to be used only as a possible indicator of impending rolling element bearing failure and should generally not be used as the primary indicator to determine when to replace the bearing.