Following topics to be discussed in this article

1. SCOPE

2. REFERENCES

3. GENERAL

4. SAFETY

5. SHIELDED METAL ARC WELDING (SMAW)

6. GAS TUNGSTEN ARC WELDING (GTAW)

7. OXYACETYLENE WELDING (FGW)

8. BRAZING

9. INSPECTION

Welding and Brazing Copper-Nickel to Austenitic Stainless Steel

1. Scope

This article describes the welding and brazing of copper-nickel to austenitic stainless steels. SES W14-F01 is a part of this standard.

2. References

Reference is made in this standard to the following documents.

American Welding Society (AWS)

A5.8 Specification for Filler Metals for Brazing

A5.11 Specification for Nickel and Nickel Alloy Covered Welding Electrodes

A5.14 Specification for Nickel and Nickel Alloy Bare Welding Electrodes and Rods

3. General

3.1 The common copper-nickel alloys are:

90 percent Cu – 10 percent Ni UNS – C70600

80 percent Cu – 20 percent Ni UNS – C71000

70 percent Cu – 30 percent Ni UNS – C71500

3.2 Intermediate temperature brazing or braze welding may not be desirable for some applications because of inferior corrosion resistance at the joint.

3.3 High temperature brazing (copper brazing) is recommended only for the 70 Cu-30 Ni alloy dissimilar metal combination, since the melting temperature ranges for 80 Cu-20 Ni and 90 Cu-10 Ni are not sufficiently high to prevent base metal melting during copper brazing.

3.4 In arc welding, in order to minimize dilution of the weld metal with iron, it may be advantageous to ‘butter’ or face the edge of the stainless.

3.5 Copper-nickel alloys are hot short (marked loss of strength and ductility at high temperatures). Excessive restraint shall be avoided in welding dissimilar metal combinations involving these alloys.

3.6 Surfaces to be joined shall be completely clean, free of oil, grease, paint, and dirt.

3.7 Peening with pneumatic guns is recommended after three passes to promote a fine grain structure.

3.8 See SES W01-F02 and W03-F02 for selecting the proper welding or brazing process.

4. Safety

Safe practices prescribed in SES W02-F01 shall be followed on plant sites.

5. Shielded Metal Arc Welding (SMAW)

5.1 Electrode: As listed in order of preference.

5.2 Preheat: 24 to 427°C (75 to 800°F) (depending upon copper content and thickness of copper-nickel).

5.3 Postheat: None.

6. Gas Tungsten Arc Welding (GTAW)

6.1 Filler Metal: As listed in order of preference.

6.2 Shielding Gas: Argon.

6.3 Preheat: 24 to 427°C (75 to 800°F) (depending upon copper content and thickness of copper-nickel).

6.4 Postheat: None.

7. Oxyacetylene Welding (FGW)

This process is not recommended for welding and brazing copper-nickel to austenitic stainless steel.

8. Brazing

8.1 Low Temperature: 688 to 899°C (1270 to 1650°F).

a. Filler Metal: Silver brazing alloys (no phosphorus). BAg-1 to BAg-3 contain cadmium. See SES W02-F01 for

safety requirements.

b. Flux: Silver brazing flux as furnished by filler metal manufacturer.

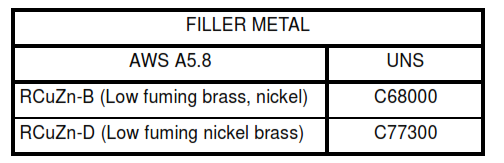

8.2 Intermediate Temperature: 899 to 1066°C(1650 to 1950°F).

a. Filler Metal:

b. Flame: Slightly oxidizing.

c. Flux: General purpose brazing flux as furnished by filler metal manufacturer.

8.3 High Temperature: 1066 to 1177°C (1950 to 2150°F).

a. Filler Metal:

b. Flux: No flux. Furnace braze in a dry hydrogen atmosphere.

9. Inspection

The amount and type of inspection required depends upon the service conditions and hazards to personnel and property. It is the responsibility of the originator to define the inspection requirements. Inspection shall be in accordance with applicable code(s).