Agitators are mechanical devices used in industrial processes to mix or agitate liquids, slurries, or other substances within a container or vessel. They are commonly found in various industries, including chemical processing, pharmaceuticals, food and beverage, water treatment, and pulp and paper manufacturing.

The primary function of agitators is to promote mixing, blending, or homogenization of the contents of a vessel by imparting mechanical energy to the fluid. This mechanical energy disrupts the fluid’s equilibrium, causing turbulence and movement within the vessel, which facilitates the desired mixing process.

Agitators typically consist of a rotating shaft with one or more blades, paddles, or impellers attached. The shaft is driven by an external motor or power source, which rotates the blades within the vessel. The design and configuration of the blades vary depending on the specific mixing requirements of the process.

What are Agitators?

Agitators, also known as mechanical mixers, are great for stirring liquids inside tanks or basins. They’re often used in tasks like mixing batches of materials in a tank or continuously treating water in places like cities. Agitators can be made to blend things together, spread substances evenly, or keep solids suspended in liquids. They can handle fluids with a wide range of thickness.

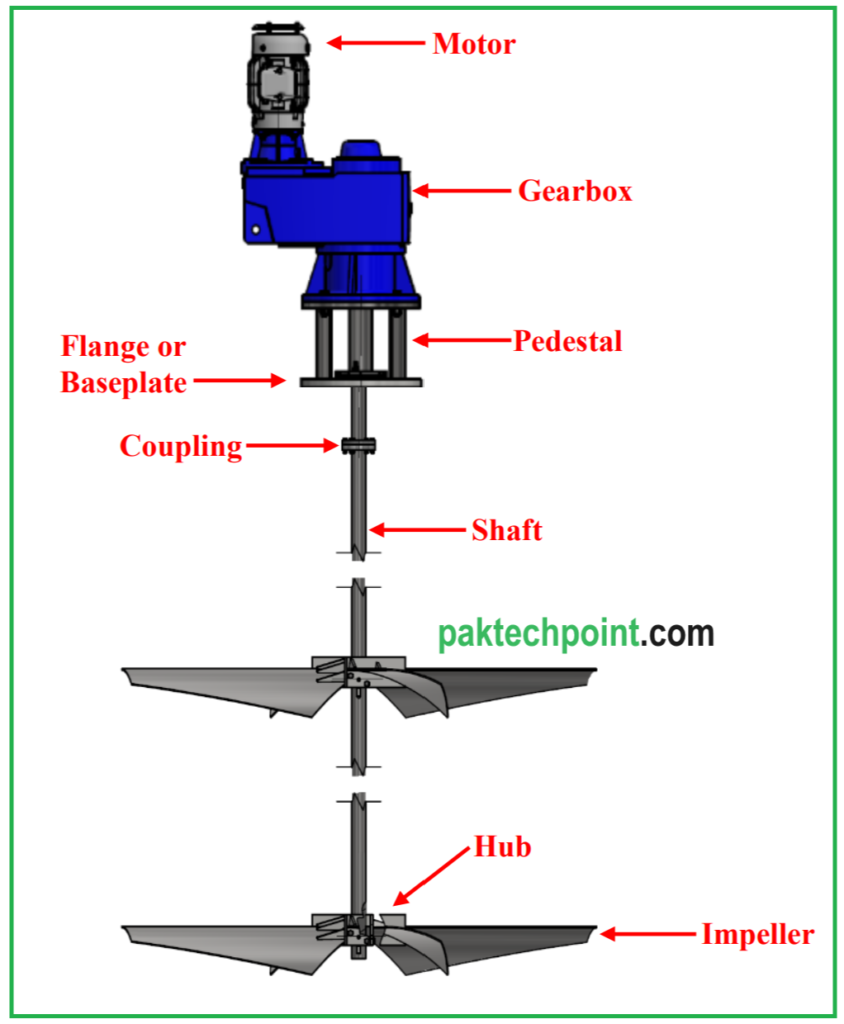

Typically, agitators are powered by an electric motor and gearbox, but there are other ways to make them work too. Below are some common parts you’ll find in an agitator:

- Motor: This provides the power to rotate the agitator.

- Gearbox: It helps control the speed and torque of the agitator.

- Shaft: This is the rod that sticks out from the motor and gearbox, and it’s what the mixing parts are attached to.

- Blades or Impellers: These are the parts that actually stir the liquid. They can come in different shapes and sizes depending on what needs to be mixed.

Overall, agitators are versatile tools that can be used in various industries for mixing and blending tasks.

Agitator Components:

The components of an agitator, also known as a mechanical mixer, include:

- Motor: This is the power source that drives the agitation process. It provides the rotational force needed to turn the agitator shaft and mix the contents of the tank or basin.

- Gearbox: The gearbox is often used to control the speed and torque of the agitator. It helps adjust the rotational speed of the agitator shaft to achieve the desired mixing intensity.

- Shaft: The shaft is a long rod that extends from the motor and gearbox into the tank or basin. It serves as the main support for the mixing components and transmits the rotational motion from the motor to the blades or impellers.

- Blades or Impellers: These are the mixing elements attached to the shaft. Blades or impellers come in various shapes and configurations depending on the specific mixing requirements. They are responsible for agitating the contents of the tank or basin by generating fluid flow and turbulence.

- Seal: A seal is often installed around the shaft where it enters the tank or basin. This helps prevent leakage of the contents and ensures that the agitator operates efficiently without losing fluids or allowing contaminants to enter the system.

- Support Structure: Depending on the size and design of the agitator, it may require a support structure to hold it in place and provide stability during operation. This structure may include mounting brackets, stands, or other support mechanisms.

These components work together to create the necessary agitation and mixing action required for various industrial processes, such as blending, dispersion, or solid suspension, inside tanks or basins.

How an Agitator Works?

An agitator works by utilizing an electric motor to drive a gearbox, which in turn rotates a shaft at a specific speed. This shaft typically holds one or more sets of impellers, with the size and design of these components tailored to the specific process requirements. There are various styles of gearboxes and impellers available, each serving different purposes.

Impellers come in different designs that influence fluid movement within the tank. Some impellers direct fluids downwards, others towards the sides, and some upwards. Additionally, different impellers produce varying levels of shear force, which can affect mixing intensity.

Mounting the agitator depends on the type of tank. In closed tanks, the agitator is typically bolted to a flange on the tank’s top. In open tanks or basins, it’s attached to a support structure running across the top. Small agitators can also be clamped onto tank sides. There are options for side and bottom entry agitators as well.

The primary purpose of an agitator is to enhance mixing by inducing fluid or solid particle movement. The desired intensity of mixing depends on the process requirements. For example, a storage tank may require gentle mixing, while blending two fluids with different viscosities may demand more vigorous mixing.

Mixing intensity, often referred to as the “level” of mixing, is determined by the bulk fluid velocity. This is calculated by dividing the impeller’s pumping rate by the tank’s cross-sectional area. Generally, low-level mixing corresponds to a low pumping rate, while high-level mixing involves a higher pumping rate.

Several factors influence mixer performance, but as a basic rule, low-level mixing involves a slower pumping rate, while high-level mixing involves a faster pumping rate. Ultimately, the design of the agitator is tailored to achieve the desired level of mixing for the specific application.

Agitator Types

These are the different types of agitators commonly used in various industrial applications:

Paddle Agitators: Paddle agitators have blades that extend to the tank walls and are used when a uniform laminar flow of liquids is desired. They are effective for gentle mixing tasks.

Anchor Agitators: Anchor agitators consist of a shaft and an anchor-type propeller, mounted centrally or at an angle. They are primarily used in reactors for mixing tasks.

Anchor agitators feature a central shaft with multiple curved blades that resemble anchors. These agitators are used for blending viscous fluids and for applications requiring low shear mixing. Anchor agitators produce both axial and radial flow, ensuring thorough mixing and preventing settling of solids.

Radial Propeller Agitators: Radial agitators have propellers similar to marine propellers, with two to four blades that move in a screw-like motion, propelling the material parallel to the shaft.

Propeller Agitators: Propeller agitators have blades tapering towards the shaft to minimize centrifugal force and maximize axial flow. They are commonly used for basic mixing jobs.

Propeller agitators consist of a rotating propeller blade attached to a shaft. They are commonly used for blending and mixing low to medium viscosity fluids in tanks or vessels. Propeller agitators generate axial flow, pushing the fluid downwards and creating a circulating motion within the tank.

Turbine Agitators: Turbine agitators combine centrifugal and rotational motion to create turbulent fluid movement. They are versatile and suitable for various mixing applications.

Turbine agitators feature multiple flat blades arranged radially on a shaft. They are suitable for mixing high viscosity fluids and are often used in applications where strong agitation is required. Turbine agitators produce both axial and radial flow, providing thorough mixing throughout the tank.

Helical Agitators: Helical agitators have blades with a twisted mechanism, resembling the threads of a screw. This design generates vigorous fluid motion, making them ideal for mixing viscous liquids.

Agitator Advantages:

Agitators offer several advantages in industrial processes where mixing, blending, or agitation is required. Some of the key advantages include:

- Efficient Mixing.

- Enhanced Mass Transfer.

- Increased Reaction Rates.

- Reduced Settling.

- Improved Heat Transfer.

- Flexible Operation.

- Control of mixing time and quality.

- Wide range of fluid viscosities.

- Terrific for solid suspension.

- Enormous variety of materials of construction.

Steps to Design An Agitator

Designing an agitator involves tailoring the equipment to meet the specific requirements of each application. Here’s how the process typically works:

- Assessment of Process Requirements: The first step is to thoroughly understand the process requirements and objectives. This includes identifying the type of mixing required (e.g., blending, suspension, dispersion), the properties of the fluids involved, operating conditions (temperature, pressure), desired residence time, and final product specifications.

- Evaluation of Fluid Dynamics: Understanding the fluid dynamics is crucial for designing an effective agitator. Factors such as viscosity, density, rheology, and flow pattern need to be analyzed to determine the optimal agitation strategy.

- Selection of Agitator Type and Configuration: Based on the process requirements and fluid dynamics analysis, the appropriate type and configuration of the agitator are selected. This includes choosing the type of impeller (e.g., axial flow, radial flow, mixed flow), the number and arrangement of impellers, shaft design, and mounting options (top-entry, side-entry, bottom-entry).

- Sizing and Power Requirements: The agitator size and power requirements are determined based on factors such as tank size, fluid volume, agitation intensity, and the desired mixing efficiency. Calculations are performed to ensure that the agitator can provide sufficient agitation energy to achieve the desired mixing results.

- Material Selection and Construction: The materials of construction for the agitator components are selected based on compatibility with the process fluids, corrosion resistance, and durability requirements. Common materials include stainless steel, carbon steel, and various alloys.

- Integration with Process Equipment: The agitator design must be compatible with other process equipment and systems, such as tanks, piping, and instrumentation. Proper integration ensures seamless operation and optimal performance of the entire system.

- Testing and Validation: Before installation, the agitator design may undergo testing and validation to ensure that it meets the specified performance criteria. This may include scale-up testing, computational fluid dynamics (CFD) simulations, or pilot-scale trials.

- Installation and Commissioning: Once the agitator is fabricated and delivered, it is installed and commissioned according to the manufacturer’s guidelines. This may involve adjustments to operating parameters and fine-tuning to optimize performance.

Throughout the design process, collaboration between the equipment manufacturer, process engineers, and end-users is essential to ensure that the agitator meets the unique requirements of the application. Additionally, ongoing support and maintenance services may be provided to ensure the continued reliability and performance of the agitator over its operational life.

Selection Criteria For Agitators

When selecting agitators, it’s important to consider specific criteria tailored to the application’s needs:

- Power Consumption: Power consumption doesn’t always correlate directly with the effectiveness of mixing. The optimal mixer choice depends on factors beyond power, such as viscosity and mixing time.

- Viscosity of Fluid: The viscosity of the fluid being mixed is a critical factor. Agitator selection should be based on how well it can handle the viscosity of the fluid and promote efficient mixing.

- Mixing Time Requirements: In applications where mixing time is crucial, the ideal agitator is one that achieves the necessary mixing in the shortest time possible while using the least amount of power.

- Size and Scale: The size of the mixer should match the scale of the operation. For tasks like blending reagents in a feed tank or mixing batches in a storage tank, a smaller mixer may suffice even if it takes a few minutes for complete mixing.

By considering these criteria, you can choose the most appropriate agitator for your specific application, ensuring efficient mixing while minimizing energy consumption and operational costs.

Power Required for Agitation

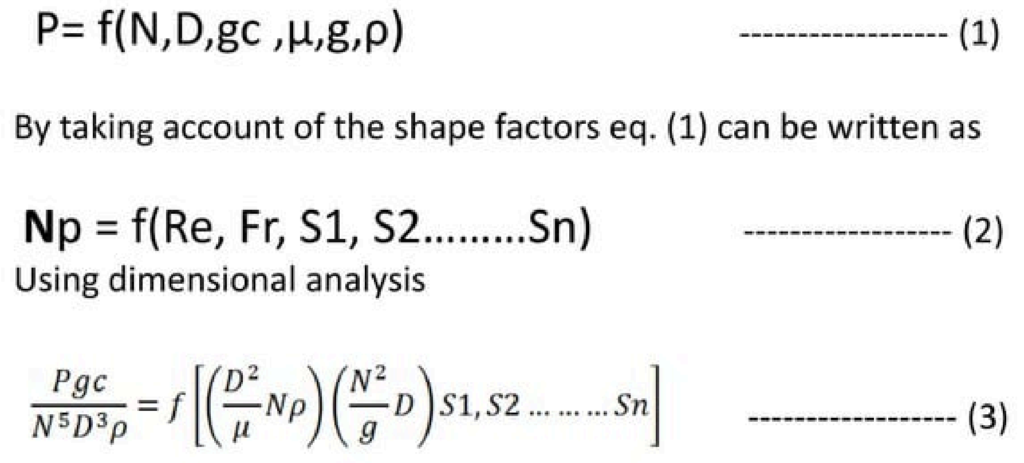

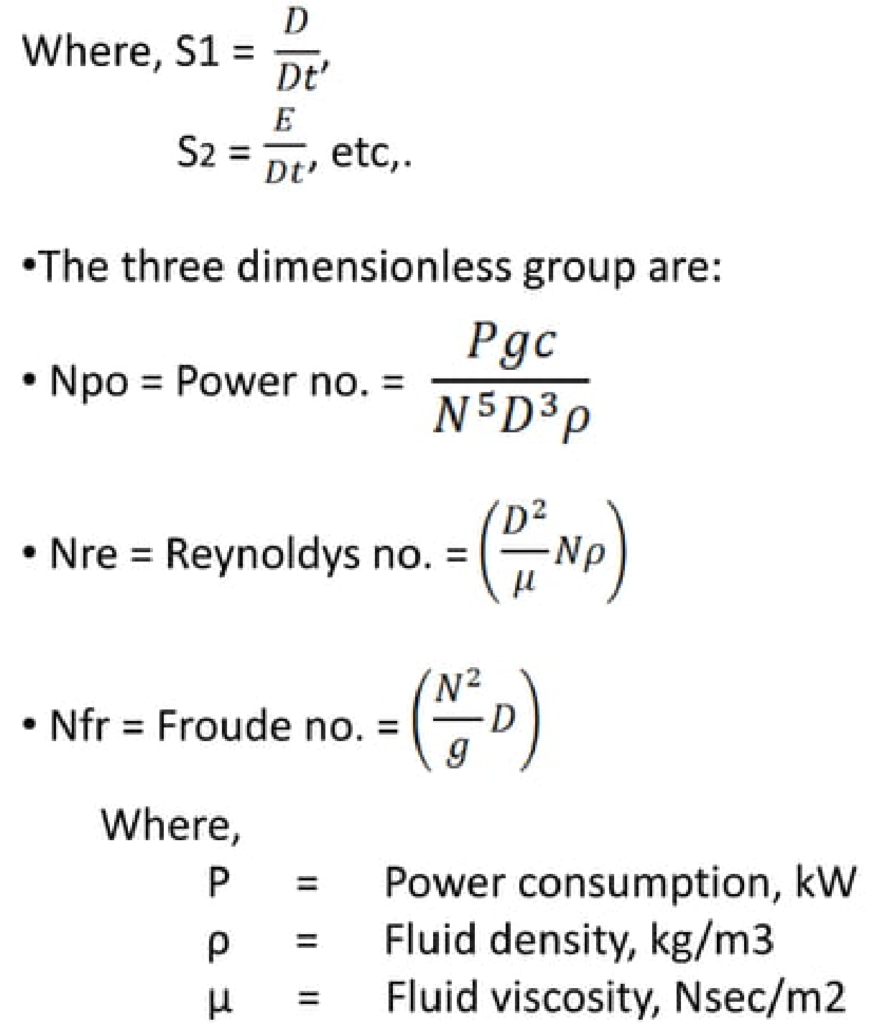

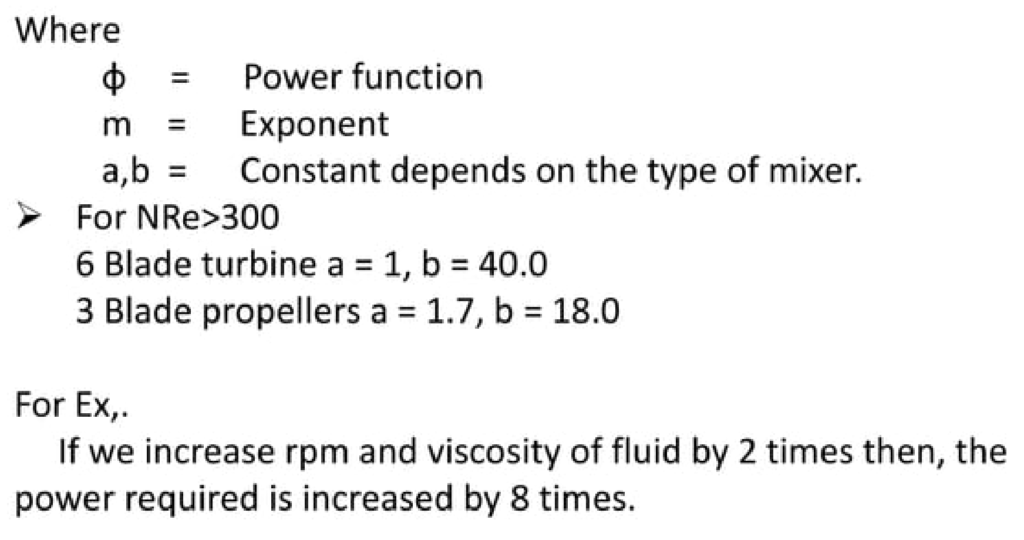

The power consumed by a mixing impeller can be studied by experimentation guided by dimensional analysis. Considering diameter of mixer, D as the basis, the power, P consumed by the mixer is a function of: