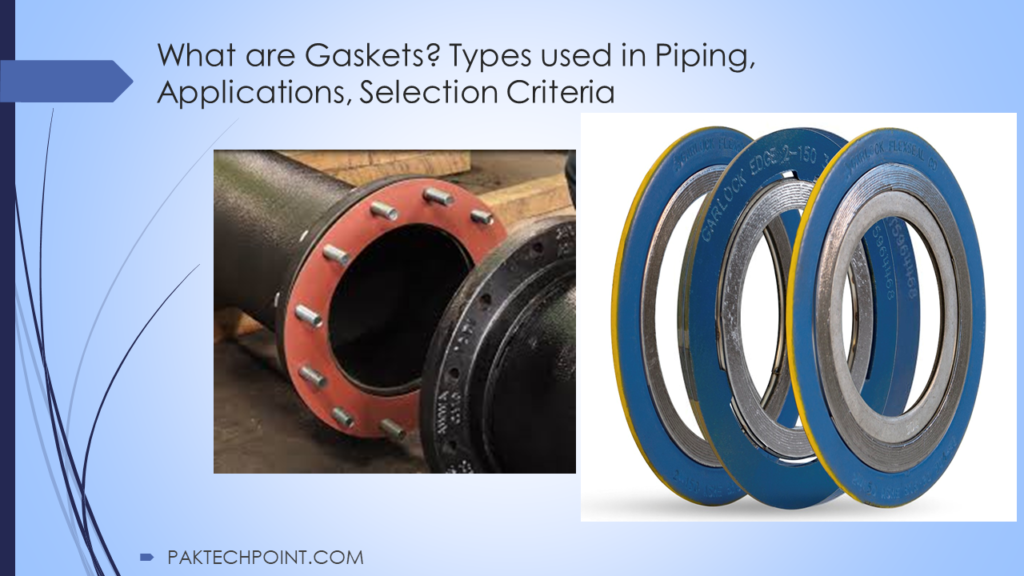

This article is about Gaskets, their uses in piping system, Gasket Selection Based on International Codes and Gasket Types in Piping.

What are Gaskets?

Gaskets are mechanical seals used to fill the space and create a tight, leak-proof connection between two or more mating surfaces, typically in machinery, piping systems, or other equipment. They serve several essential functions:

- Sealing: Gaskets prevent the leakage of gases, liquids, or other substances from the joint between two surfaces. They effectively seal the space, ensuring that the contents inside a vessel or piping system remain contained.

- Isolation: Gaskets can electrically isolate different components or parts in machinery or electrical systems, preventing the flow of electrical currents or minimizing the risk of galvanic corrosion in metal connections.

- Compensation for Surface Irregularities: Even well-machined surfaces can have minor irregularities. Gaskets fill these gaps, compensating for imperfections and providing a uniform sealing surface.

- Vibration Dampening: In some applications, gaskets also help absorb vibrations and shocks, reducing wear and tear on equipment.

Gaskets come in various shapes, sizes, and materials, and their selection depends on the specific application, operating conditions (including temperature and pressure), and the fluids or gases being sealed. Common materials for gaskets include rubber, cork, paper, metal, and composite materials. The choice of gasket material is critical to ensure compatibility with the substances being sealed and the environmental conditions in which they will operate.

Gasket Selection Based on International Codes

In piping systems and industrial applications, selecting the right gaskets is crucial to ensure the integrity and safety of the system. Here are some key points related to gasket selection, specifically focusing on metallic ring joint gaskets:

Suitability for the Intended Service:

- Gaskets must be chosen based on the specific service conditions they will encounter. This includes considerations such as temperature, pressure, and the type of fluid or gas being transported.

- Different gasket materials are designed to handle various operating conditions. For instance, high-temperature applications may require gaskets with materials that can withstand elevated temperatures without deforming or losing their sealing properties.

- Compatibility with the intended service ensures that the gasket will effectively seal the joint and prevent leaks over time.

Compatibility with Flange Facing, Rating, and Bolting:

- Gaskets must be compatible with the flange facing, which is the surface of the flange where the gasket sits. Proper compatibility ensures a reliable seal.

- The flange rating, which defines the pressure-temperature capabilities of the flange, should also match the gasket’s capabilities.

- Bolting refers to the nuts and bolts used to secure the flanges and gaskets together. Gaskets should be selected to work harmoniously with the chosen bolting system.

Gasket Types in Piping

1. Metallic Ring Joint Gaskets:

- Metallic ring joint gaskets, such as octagonal ring joint gaskets (Type R) per ASME B16.20, have specific design and application guidelines.

- They are commonly used with API SPEC 6A Type 6B flanges and ASME RTJ (Ring Type Joint) flange types, which are often found in high-pressure and critical applications like oil and gas.

- The choice of metallic ring joint gasket material should align with the service conditions. Materials like soft iron or low carbon steel are suitable for ring type joints and may be used in severely corroded services.

- Rubber-coated ring joint gaskets can be employed in applications where corrosion is a concern. The rubber coating enhances sealing performance while the underlying metallic structure provides strength and durability.

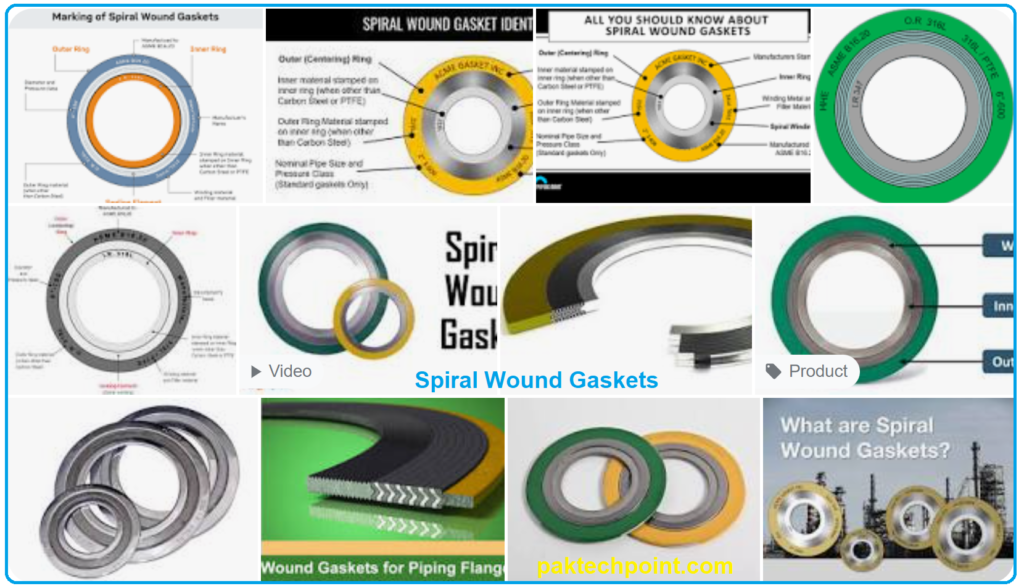

2. Spiral Wound Gaskets

Spiral wound gaskets are a common choice for sealing flanged connections in industrial applications. Here are some important considerations and requirements related to spiral wound gaskets:

Conformance to ASME B16.20:

- Spiral wound gaskets must conform to the specifications outlined in ASME B16.20, which provides guidelines for the design and manufacturing of these gaskets. This ensures consistency and reliability in their performance.

Filler Material Suitability:

- The filler material used in spiral wound gaskets should be carefully selected to match the intended design conditions of the application.

- In oxidizing environments, where there is a presence of oxygen or other oxidizing agents, the maximum temperature for gaskets with graphite filler material is limited to 425°C. Beyond this temperature, graphite may not maintain its sealing properties effectively.

- It’s important to avoid filler materials that deteriorate at elevated temperatures, such as Teflon (PTFE), in hydrocarbon services. PTFE and similar materials can degrade when exposed to high temperatures, compromising the gasket’s performance.

Material Selection for Hydrocarbon Services:

- For general hydrocarbons and process hydrocarbon services, including steam, ASME B16.20 recommends the use of spiral wound gaskets with specific materials:

- The winding material should be 316 stainless steel.

- The filler material should be high purity flexible graphite. Graphite is known for its excellent sealing properties, especially in high-temperature and high-pressure applications.

Matching Inner and Outer Rings with Flange Material:

- To ensure compatibility and proper sealing, the material of both the inner and outer rings of the spiral wound gasket should match the material of the flanges.

- This matching helps prevent issues such as galvanic corrosion and ensures a reliable seal between the gasket and flange.

Outer and Inner Ring Requirements:

- Outer rings are required for all pipe sizes. These rings help maintain the shape and stability of the gasket during installation and operation.

- Inner rings are required for specific conditions, including:

- Flanges with a size of 24 inches and larger.

- Flanges with a class rating of 900# and above (where applicable).

- Spiral wound gaskets with PTFE filler materials.

- Flanges used in vacuum services, where maintaining a seal is critical due to the absence of external pressure.

In conclusion, spiral wound gaskets are versatile sealing solutions used in various industrial applications. Proper selection of filler materials, adherence to design standards like ASME B16.20, and matching the gasket’s inner and outer rings with flange materials are essential factors for ensuring effective sealing and system integrity in different operating conditions. These considerations help prevent leaks and maintain the reliability of flanged connections.

3. Metal Grooved (Kammprofile) Gaskets

Metal Grooved, or Kammprofile, gaskets offer an alternative sealing solution to spiral wound gaskets, particularly in situations where specific challenges such as pressure fluctuations, temperature differentials, and bolt stress relaxation need to be addressed. Here are key points regarding Metal Grooved (Kammprofile) gaskets:

Application as an Alternative:

- Metal Grooved gaskets are used as an alternative to spiral wound gaskets in piping systems.

- They are especially suitable when the system experiences:

- Pressure fluctuations: These gaskets can effectively seal joints even when the system pressure varies.

- Temperature differentials across the flange face: They can handle situations where one side of the flange is at a significantly different temperature from the other side.

- Bolt stress relaxation: Due to their design, Metal Grooved gaskets can accommodate changes in bolt stress over time.

Sealing Facing Material:

- Metal Grooved gaskets typically feature a sealing facing material, which in this case is graphite.

- Graphite is chosen for its excellent sealing properties, even in high-temperature and high-pressure environments.

- The graphite facing material helps create a reliable and tight seal between flange surfaces.

Outer Centering Ring:

- Metal Grooved gaskets are equipped with an outer centering ring.

- This centering ring serves several purposes, including:

- Ensuring proper alignment of the gasket during installation.

- Distributing the load evenly across the sealing elements.

- Enhancing the stability and integrity of the gasket, particularly in situations where the flanges may be subject to movement or thermal expansion.

Versatile Sealing Solution:

- Metal Grooved gaskets are versatile and can be used in a range of applications.

- They are effective for both raised face and flat face flanges.

- These gaskets can handle various fluid and gas media, making them suitable for a wide spectrum of industries, including oil and gas, petrochemical, and manufacturing.

Benefits of Metal Grooved Gaskets:

- Reliable Sealing: Metal Grooved gaskets are designed to provide a dependable and long-lasting seal even in challenging conditions.

- Temperature and Pressure Resistance: Their use of graphite and robust construction enables them to withstand high temperatures and pressures.

- Accommodation of Flange Movement: Metal Grooved gaskets can accommodate movement in the flanges due to factors like thermal expansion and contraction.

- Reduced Gasket Creep: The design helps minimize gasket creep and extrusion, contributing to the gasket’s longevity.

In summary, Metal Grooved (Kammprofile) gaskets are a valuable sealing solution, especially in situations where pressure variations, temperature differentials, and bolt stress relaxation are significant concerns. Their use of graphite sealing material, outer centering ring, and robust design make them a reliable choice for achieving and maintaining tight seals in demanding industrial environments.

4. PIKOTEK or Equivalent Gaskets

PIKOTEK gaskets, while offering certain advantages, have specific limitations that warrant careful consideration in their application. In particular, these gaskets should not be utilized in refinery and gas plant environments due to their potential compatibility issues. Furthermore, they should not be employed in services where temperatures reach 280°F or higher. However, for scenarios involving corrosive water services and concerns about flange face corrosion, an alternative option can be explored:

PIKOTEK Gaskets: Limitations

- Refinery and Gas Plant Restrictions: PIKOTEK gaskets should not be used in refineries and gas plants. These environments can involve complex and harsh conditions that might not align with the properties of PIKOTEK gaskets.

- Temperature Threshold: PIKOTEK gaskets are not suitable for services operating at temperatures of 280°F and above. Temperatures in this range could affect the performance and integrity of the gaskets.

Alternative Gasket Option: Teflon-Sealed Glass Reinforced Epoxy

- Corrosive Water Services: In situations where water services are corrosive and flange face corrosion is a concern, an alternative gasket option can be considered. This alternative involves using gaskets with a unique construction that offers enhanced resistance to corrosion.

- Gasket Composition: The alternative gasket consists of a Teflon-sealed, glass reinforced epoxy material that is laminated to a core made of 316 stainless steel. This composition combines the durability of stainless steel with the protective properties of Teflon and glass reinforced epoxy.

5. Insulating Gaskets:

Insulating gaskets, such as PIKOTEK gaskets or those meeting equivalent standards, play a vital role in certain scenarios by preventing galvanic corrosion and promoting electrical isolation in flanged joints. However, their application is subject to specific criteria and exemptions based on the nature of the service and the potential risks involved.

Appropriate Usage of Insulating Gaskets:

- Galvanic Corrosion Prevention: Insulating gaskets, including PIKOTEK gaskets or equivalent alternatives, are required in cases where flanged joints involve dissimilar metals that pose a risk of galvanic corrosion. Galvanic corrosion occurs when two dissimilar metals come into contact and create an electrically conductive path, leading to corrosion.

- Cathodic Protection: Flanged joints utilized for cathodic protection, which involves preventing corrosion of metal surfaces by using sacrificial anodes or direct current, also warrant the use of insulating gaskets. These gaskets assist in maintaining the integrity of the cathodic protection system.

Exemptions from Insulating Gasket Requirement:

- Dry Hydrocarbon Gas Service: In scenarios involving dry hydrocarbon gas service within dry areas, insulating gaskets are not mandatory. The absence of moisture in such environments reduces the likelihood of galvanic corrosion.

- Non-Metallic Gasket Limitation: When the service temperature exceeds the capability of non-metallic gaskets, insulating gaskets are not necessary. Non-metallic gaskets have specific temperature limitations beyond which their performance might be compromised.

- Absence of Galvanic Corrosion Risk: When the designer can demonstrate that no galvanic corrosion will occur between dissimilar metals in a particular joint, insulating gaskets may not be required. This exemption applies when the combination of metals and conditions present does not promote galvanic coupling.

- Ineffectiveness in Flammable Services: In certain instances involving flammable services, where insulating gasket kits might not effectively prevent electrical external bonding between dissimilar metals, the requirement for insulating gaskets may be waived. This can occur due to factors such as contacts with pipe supports, structural components, and other electrical pathways.

6. Metal Jacketed Gasket

Metal jacketed gasket shall not be used in pipe flanges.

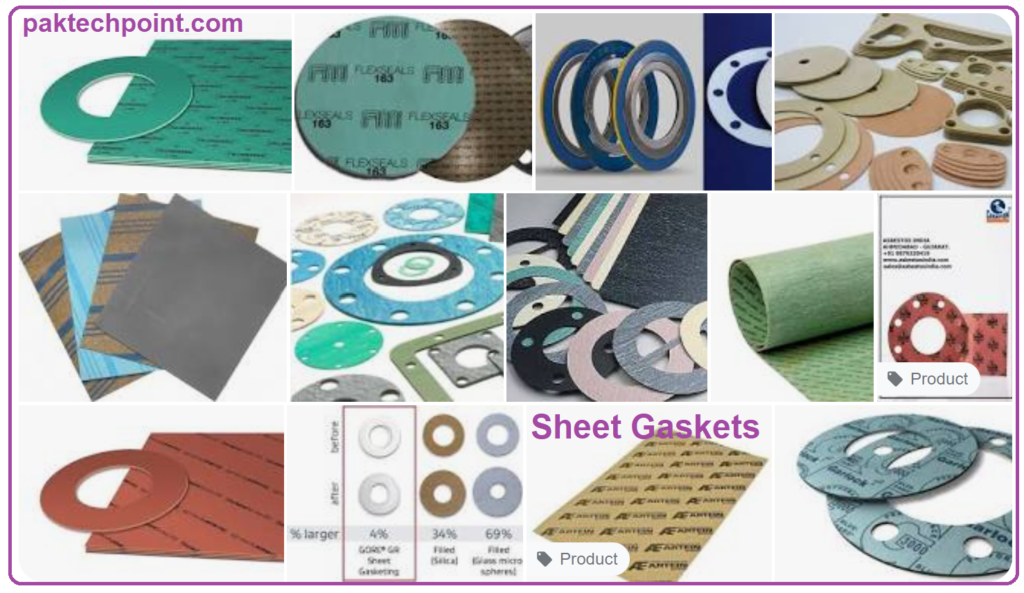

7. Sheet Gaskets for Various Applications

Sheet gaskets are vital components in creating reliable seals in various industrial settings, including piping systems. Their selection and application depend on factors such as the service conditions, flange type, and temperature requirements. Here are key considerations for the use of sheet gaskets:

1. Compliance with ASME B16.21: All sheet gaskets must adhere to the specifications outlined in ASME B16.21, which provides essential guidelines for their design and performance.

2. Material Suitability: The choice of sheet gasket material is crucial, as it must align with the specific conditions of the intended application.

3. Compressed Synthetic Fiber: In non-hazardous services with Class 125 and 150 flat face flanges, sheet gaskets made from compressed synthetic fiber with an oil-resistant binder are suitable. These gaskets can withstand temperatures of up to 230°C.

4. Synthetic Rubber Gaskets: For services involving acids with concentrations up to 70% and temperatures up to 65°C, full-face sheet gaskets made from synthetic rubber (ASTM D1418 Class CSM) can be employed. However, for more concentrated sulfuric acid (above 70%), including oleum, and nitric acid across all concentrations, gaskets made from ASTM D1418 class FKM elastomer should be used on flat face flanges. When raised face flanges are used, the flange finish should fall within the range of 3.2 to 6.4 micrometers Ra, and gaskets should be PTFE-filled spiral wound Alloy 20 stainless steel with a stainless steel inner ring.

5. Approval for Special Cases: Any applications involving acids other than those mentioned above must receive approval from the Chairman of the Piping Standards Committee in CSD. This ensures that gasket selection aligns with the unique demands of the specific service conditions.

6. Plastic Flanges: In cases where plastic flanges are utilized, full-face sheet gaskets composed of elastomeric material, with a thickness of 3 mm and a Shore A Durometer hardness between 50 and 60, may be used. For services involving wet chlorine or hypochlorite, the elastomer must meet the ASTM D1418 class CSM standard.

In summary, the selection of sheet gaskets is contingent upon several factors, including the type of service, temperature range, and flange configuration. Ensuring that the chosen gasket material aligns with these variables is essential for creating effective and reliable seals in piping systems. Moreover, obtaining approval from relevant authorities for specialized applications guarantees the safety and integrity of the system.