Dissolved Gas Analysis (DGA) is a diagnostic technique used in various industries, primarily in the electrical power and oil industries, to assess the condition of insulating fluids and detect potential issues in high-voltage electrical equipment, such as transformers and circuit breakers. It involves analyzing the gases dissolved in the insulating oil or fluid within these devices. Here’s how DGA works and why it’s important:

How Dissolved Gas Analysis Works:

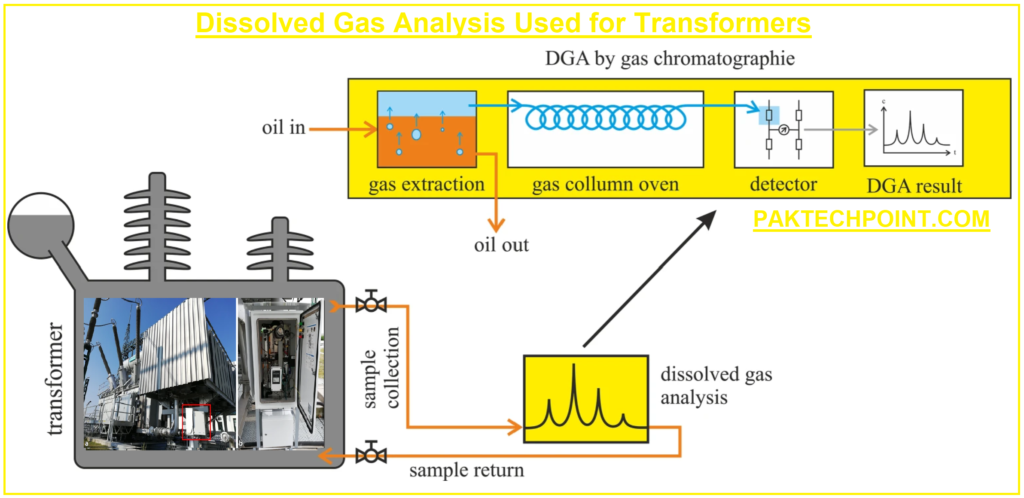

- Sample Collection: A small sample of insulating oil is collected from the electrical equipment, typically from a sample valve or port. The sample should be representative of the fluid within the equipment.

- Gas Extraction: The collected oil sample is degassed to remove any free or entrapped gases. This is usually done by heating and/or applying a vacuum to the sample. Removing free gases ensures that the analysis focuses on only the dissolved gases.

- Gas Analysis: The degassed oil is then subjected to gas chromatography or other analytical techniques to identify and quantify the concentration of various dissolved gases. The key gases of interest include hydrogen (H2), methane (CH4), ethylene (C2H4), acetylene (C2H2), and carbon monoxide (CO), among others.

- Interpretation: The concentrations of these gases are compared to established industry guidelines and standards. Changes in gas concentrations, their ratios, and their rate of change over time can provide valuable information about the condition of the electrical equipment.

Following is the one by one explanation.

1. Sample Collection

Sampling is a critical step in Dissolved Gas Analysis (DGA) to assess the condition of transformer oil and detect potential issues in electrical transformers. Two common methods for collecting oil samples are using oil sample tubes and glass syringes:

Oil Sample Tube:

- Purpose: An oil sample tube is designed to draw, retain, and transport a sample of transformer oil while preserving it in the same condition as inside the transformer, including all dissolved fault gases.

- Design: It is typically a gas-tight borosilicate glass tube with a capacity of 150 ml or 250 ml. The tube has two airtight Teflon valves at both ends.

- Usage: When collecting a sample, the Teflon valves are used to seal the tube. Synthetic tubes can be connected to these valves for drawing the sample from the transformer. This process ensures that the sample remains uncontaminated by the atmosphere.

- Septum: The tube may have a septum arrangement on one side, allowing for the extraction of a sample for moisture content testing.

- Transport: To maintain the integrity of the samples during transport, thermo foam boxes are used, preventing exposure to sunlight.

Glass Syringe:

- Purpose: Oil syringes are an alternative method for obtaining oil samples from transformers.

- Volume: They are available in various volumes, with 50ml being a common size.

- Quality: The quality and cleanliness of the syringe are crucial, as they ensure the sample’s integrity before analysis.

Both of these methods aim to collect transformer oil samples without introducing contamination or altering the composition. These samples are then subject to laboratory analysis, including Dissolved Gas Analysis, to assess the condition of the transformer and detect any emerging issues or faults. Proper sampling techniques are essential to ensure the accuracy and reliability of the diagnostic results.

2. Gas Extraction:

Extraction is a crucial step in Dissolved Gas Analysis (DGA), which involves removing gases from transformer oil for analysis. There are different methods for this process:

1. “Rack” Method (ASTM D3612A):

- This traditional method requires the oil to undergo a high vacuum in a complex, glass-sealed system to extract most of the gas.

- The collected gas is measured in a graduated tube by breaking the vacuum with a mercury piston.

- A gas-tight syringe is used to inject the gas into a Gas Chromatograph (GC) for analysis.

2. Multi-Stage Gas Extractor:

- This method, developed as an improved version of ASTM D3612A, allows a single sample of transformer oil to be exposed to vacuum multiple times at ambient temperature.

- In this apparatus, a fixed volume of sample oil is drawn from a sample tube into a degassing vessel under vacuum to release gases.

- These gases are isolated and measured using a mercury piston at atmospheric pressure before being transferred to a gas chromatograph using a gas-tight syringe.

- This method is based on the Toepler principle.

3. Head Space Extraction (ASTM D3612-C):

- This method involves agitating and heating the oil to release gases into a sealed vial’s “headspace.”

- Once extracted, the gases are sent to a gas chromatograph for analysis.

Specialized Techniques:

- Some advanced techniques, such as Headspace Sorptive Extraction (HSSE) or Stir Bar Sorptive Extraction (SBSE), are also used for gas extraction.

In all these methods, the goal is to efficiently and accurately collect gases from the transformer oil so that their composition can be analyzed using gas chromatography. This analysis provides valuable insights into the condition of the transformer and helps detect any potential issues or faults.

3. Gas Analysis:

Gas Analysis in Transformer Oil:

When analyzing gases in transformer oil, nine specific gases are typically examined. These gases provide valuable information about the condition of the transformer. The gases of interest are:

1. Atmospheric Gases:

- Nitrogen (N2)

- Oxygen (O2)

2. Oxides of Carbon:

- Carbon Monoxide (CO)

- Carbon Dioxide (CO2)

3. Hydrocarbons:

- Acetylene

- Ethylene

- Methane

- Ethane

4. Hydrogen (H2)

Gas Chromatography:

The process of analyzing these gases involves the use of a gas chromatograph. Here’s how it works:

- Sample Extraction: Gases are extracted from the transformer oil.

- Injection: The extracted gases are injected into a gas chromatograph.

- Column Separation: Inside the chromatograph, the gases are transported through a column. This column selectively retards the movement of different gases.

- Detection: As the gases travel through the column, they are identified based on their differing retention times. The separated gases pass by a detector at different times.

- Chromatogram: The data collected, showing the detector signal versus time, is called a chromatogram. It provides a visual representation of the separated gases.

Detection Methods:

- Atmospheric gases like nitrogen and oxygen are detected using a thermal conductivity detector.

- Hydrocarbons and oxides of carbon are detected using a flame ionization detector.

- In cases where oxides of carbon are present in very low concentrations, a methanator is employed to convert them into methane, which can then be detected using a flame ionization detector.

This gas analysis process allows for the identification and quantification of these gases, providing critical information about the transformer’s health and any potential issues or faults.

Why Dissolved Gas Analysis Is Important:

DGA is important for several reasons:

- Fault Detection: Changes in the concentrations of specific gases can indicate the presence of electrical faults, such as overheating, arcing, or partial discharges within the equipment. These faults can lead to equipment failure if not addressed promptly.

- Early Warning: DGA can provide early warning signs of potential issues, allowing maintenance teams to take preventive actions before a catastrophic failure occurs. This helps in minimizing downtime and repair costs.

- Condition Assessment: DGA helps assess the overall health and condition of high-voltage electrical equipment. Regular monitoring and trend analysis can provide insights into long-term equipment performance.

- Safety: Identifying fault conditions early can enhance the safety of personnel working with or near high-voltage equipment, as catastrophic failures can pose serious risks.

- Asset Management: DGA data can inform asset management decisions, including when to replace or refurbish equipment. It helps in optimizing the lifespan and reliability of assets.

- Environmental Impact: Monitoring gas emissions from electrical equipment is also important for environmental compliance and reducing greenhouse gas emissions.

In summary, Dissolved Gas Analysis is a valuable diagnostic tool used to assess the condition of electrical equipment by analyzing the gases dissolved in insulating fluids. It plays a critical role in predictive maintenance, early fault detection, and ensuring the safe and reliable operation of high-voltage electrical assets.

Furan Analysis of Transformer Oil:

In transformers, the insulation within the core and winding is often made of paper, which is primarily composed of cellulose molecules. Over time, this paper insulation ages, and its long chains of molecules break down into shorter segments, making it brittle, much like the pages of old books. However, within a transformer, this aging process is accelerated due to the oxidation that occurs in the surrounding oil. When the paper insulation becomes mechanically weak, it may fail during electrical short circuits, leading to electrical breakdown. Hence, monitoring the condition of paper insulation is crucial in power transformers.

Traditional testing methods cannot extract a piece of paper insulation from a live transformer for examination. Fortunately, a non-invasive technique called Furan analysis has been developed to assess the condition of paper insulation without physical contact.

How Furan Analysis Works:

- Cellulose Degradation: As paper insulation ages within the transformer, it undergoes degradation. The long cellulose chains break into shorter segments.

- Furan Compounds: When oil interacts with the aged paper, unique oil-soluble compounds called Furan compounds are released. The most predominant one is 2-Furfural.

- Sensitivity: Furan analysis is highly sensitive, capable of detecting damage to a few grams of paper within the transformer oil, even in large transformers.

- Assessment: By tracking the rate of increase in Furan compounds in the transformer oil over time, experts can assess the condition and remaining life of the paper insulation. This analysis provides valuable insights into the transformer’s health and helps determine when maintenance or replacement is necessary.

Furan analysis is considered a significant diagnostic test and is often regarded as the best method for evaluating the lifespan of a transformer. It provides a sensitive and reliable means of monitoring the condition of paper insulation, which is critical for ensuring the reliable operation of power transformers.