MCC meaning in electrical is motor control centre. Usually type of panel and combination of many components like feeders, electrical buses, circuit breaker and fuses etc with having common power bus. MCC is used in industrial and process applications where lots of motors are used with variable loads. This panel makes it centralized. In some places Control panel and Motor control centre are used in one panel.

In many businesses and industries, there’s a need for several electric motors to work together. It’s often convenient to control these motors from one central place. This is where a motor control center (MCC) comes in. Imagine an MCC as a group of special starter units put together in one box. A starter unit is like a control panel for a motor. It has everything needed, like fuses or circuit breakers for safety, and a way to turn the power off. It might also have buttons and lights to show what’s happening with the motor. So, an MCC is like a team of these starter units working together in one big box.

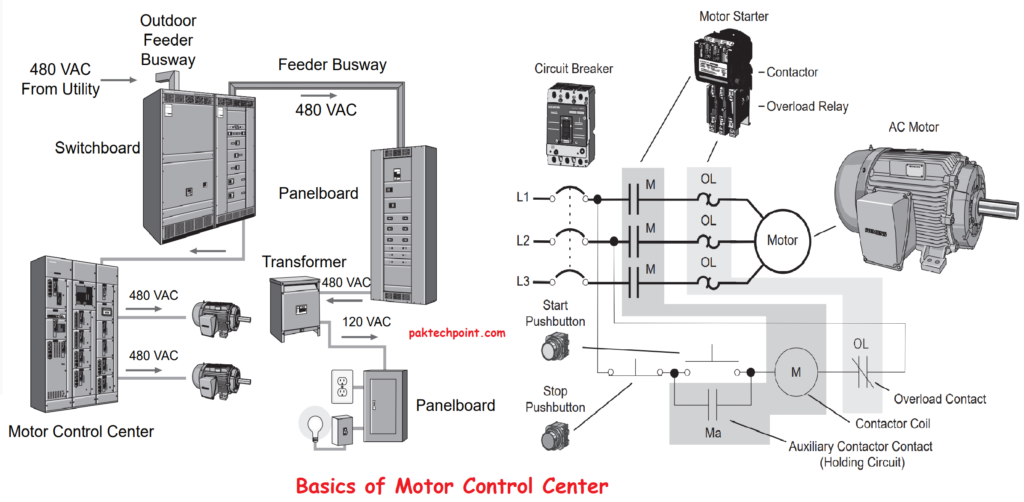

Basics of MCC Motor Control Center

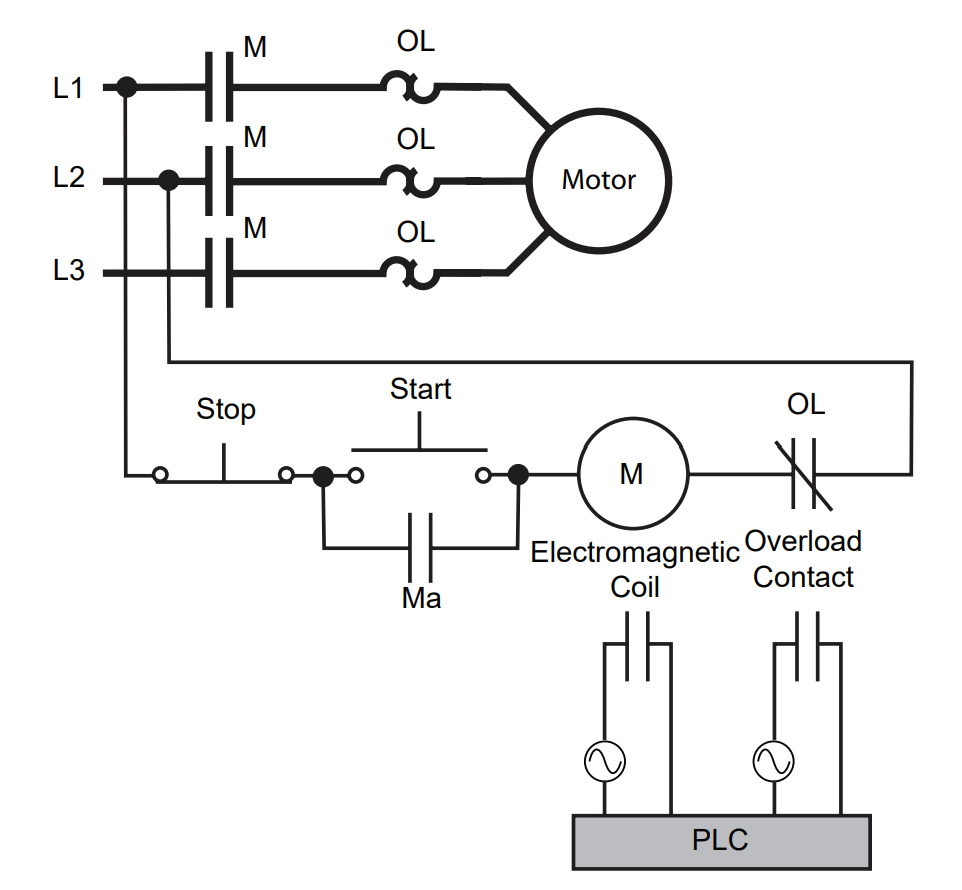

When we use motors, we need a way to control them. You’ve already learned about control products that help manage how motors work. One simple way to control an AC motor is to turn it on and off. This is where a motor starter comes in. It’s like a team made up of a contactor and an overload relay.

The contactor is responsible for starting and stopping the motor. When we want the motor to run, the contactor’s contacts close, allowing electricity to flow to the motor. When we want the motor to stop, the contacts open, cutting off the power. We use start and stop buttons and other devices to control the contactor, making it all happen.

The overload relay is like the motor’s protector. If the motor gets overloaded, the overload relay stops the power going to the motor. However, it doesn’t protect the wiring from short-circuits, so we also use fuses or a circuit breaker for that.

Usually, one motor starter takes care of one motor. If there are just a few motors spread out in different places, the control parts can be put in a box near each motor.

The following picture shows the simple diagram and circuitry.

This operation is like manual panel system and motor is located at far distance from master control room. Engineers and technicians easily access the circuitry and can check the any fault or regular checking of the circuitry.

In the realm of electrical engineering, Motor Control Centers (MCCs) play a pivotal role in industrial operations by providing efficient control and management of motors and electrical devices. A Motor Control Center is a crucial component of complex industrial setups, ensuring the seamless operation of machinery, safety, and energy efficiency. This article will delve deep into the technical intricacies of MCCs, shedding light on their definition, working principles, components, types, applications, and their significant role in modern industries.

Defining Motor Control Centers (MCCs)

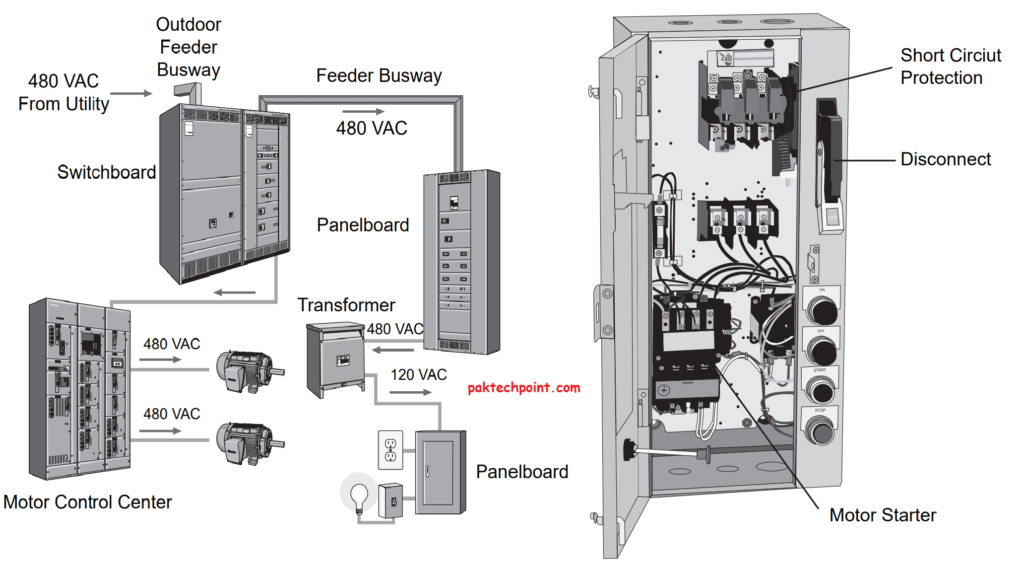

A Motor Control Center (MCC) is an integrated assembly of one or more enclosed sections designed to control and distribute electric power to motors in industrial processes. It serves as a centralized control panel that houses various electrical components, such as motor starters, drives, circuit breakers, control devices, and communication interfaces. The primary objective of an MCC is to streamline the operation, protection, and monitoring of motors and related equipment within a facility.

How Do Motor Control Centers Work?

MCCs operate on the principle of receiving electrical power from a main source and distributing it to individual motors based on specific control commands. The working process involves various components working in tandem to regulate the motor’s speed, direction, and protection. Here’s a breakdown of how an MCC works:

- Power Distribution: The MCC receives electrical power from the main distribution panel. This power is then distributed to various motor starters and control devices within the MCC.

- Motor Starters: Each motor is equipped with a motor starter, which includes a contactor to control power supply to the motor and overload protection to safeguard against excessive current.

- Control Devices: The MCC houses a variety of control devices such as push buttons, selector switches, and pilot lights. These devices allow operators to start, stop, and control the motors remotely.

- Programmable Logic Controllers (PLCs): In modern MCCs, PLCs are employed to provide advanced control and automation capabilities. PLCs receive input signals from sensors and operators and generate output signals to control motor operations.

- Communication Interfaces: MCCs are often integrated with supervisory control and data acquisition (SCADA) systems for remote monitoring and diagnostics. This enables real-time tracking of motor performance and troubleshooting.

- Protection Mechanisms: MCCs incorporate various protective devices like circuit breakers, fuses, and ground fault detection systems to ensure the safety of equipment and personnel.

Components of a Motor Control Center

A Motor Control Center is composed of several essential components that collectively contribute to its functionality:

- Busbars: These are conductive bars that carry electrical current throughout the MCC, distributing power to various sections.

- Motor Starters: These are contactors or soft starters responsible for initiating and controlling the speed of the motor.

- Overload Relays: Overload relays protect motors from overheating by detecting excessive current and interrupting power.

- Circuit Breakers: MCCs feature circuit breakers that act as switches to protect against short circuits and overloads.

- Variable Frequency Drives (VFDs): VFDs regulate the speed and torque of motors by varying the frequency and voltage of the power supply.

- Control Devices: Push buttons, selector switches, and indicator lights allow operators to control and monitor motor operations.

- Communication Modules: Modern MCCs incorporate communication modules to enable remote monitoring, diagnostics, and data collection.

- Programmable Logic Controllers (PLCs): PLCs automate processes and enhance control capabilities by processing input signals and generating output commands.

Types of Motor Control Centers

Motor Control Centers come in various types, each catering to specific industrial needs:

- Full Voltage (Non-Reversing) MCCs: These are used for controlling motors that run in a single direction at full voltage.

- Reversing MCCs: Designed for motors that require reversal of rotation, these MCCs include two sets of motor starters to change the direction of the motor.

- Combination (Full Voltage and Reversing) MCCs: These combine the features of both full voltage and reversing MCCs, allowing control over motor direction and speed.

- Multi-Speed MCCs: These MCCs are equipped with multiple motor starters to regulate the speed of the motor according to specific requirements.

- Variable Frequency Drive (VFD) MCCs: VFD MCCs integrate variable frequency drives to provide precise control over motor speed and energy efficiency.

- Intelligent MCCs: Incorporating advanced technologies like PLCs and SCADA, these MCCs offer enhanced automation, remote monitoring, and diagnostics capabilities.

What is a Smart MCC?

Definition of a Smart MCC:

A smart Motor Control Center (MCC) is an evolution of the traditional MCC concept. Like its conventional counterpart, it is composed of vertical sections with vertical and horizontal power buses and wiring, primarily housing combination motor control units. However, what sets a smart MCC apart is the incorporation of intelligent devices to control and monitor motors, track energy consumption and power quality, and establish rapid communication via data networks, such as PLCs or process control systems.

Differentiating Features:

- Intelligent Devices: Smart MCCs go beyond the limited use of intelligent devices found in traditional MCCs. These devices enable advanced control and monitoring capabilities.

- Data Networking: A central feature of smart MCCs is the robust integration of data networking, allowing seamless communication between components and systems.

Advantages of Smart MCCs:

- Reduced Installation and Commissioning Costs: The intelligence and networking in smart MCCs streamline the installation and commissioning processes, as devices can be configured and monitored remotely, reducing the need for physical intervention.

- Reduced Maintenance Costs: Smart MCCs provide real-time data about motor and system performance, allowing for predictive and condition-based maintenance, minimizing downtime and unplanned breakdowns.

- Reduced Energy Costs: Energy monitoring capabilities of smart MCCs enable energy consumption analysis, allowing for optimized energy usage and potentially reducing energy costs.

- Reduced Downtime: With continuous monitoring and predictive maintenance, the risk of unexpected failures is minimized, leading to reduced downtime and improved overall system reliability.

- Increased System Efficiency: Smart MCCs can optimize motor control parameters based on real-time data, ensuring motors operate at peak efficiency, which contributes to energy savings.

- Increased System Information: The real-time data and insights provided by smart MCCs enhance the operator’s understanding of system performance, enabling better decision-making and more effective system management.

In summary, the shift from traditional MCCs to smart MCCs is marked by the integration of intelligent devices and data networking, resulting in a host of advantages that drive cost reduction, increased profitability, and improved overall system efficiency. By harnessing advanced monitoring, control, and communication technologies, smart MCCs pave the way for enhanced industrial automation and optimized energy management.

Traditional Motor Starters:

Traditional electromechanical motor starters are capable of basic functions such as full voltage starting, reversing rotation, and limited reduced voltage starting. They also offer basic overload protection and, with the addition of a solid-state overload relay, some additional features like phase loss protection. However, these starters lack the ability to efficiently communicate vital information about factors affecting motor life and performance, such as the number of starts, overload trips, running time, heat, shock, and vibration.

Smart MCCs Motor Control Center:

Smart MCCs revolutionize motor control and monitoring by incorporating intelligent devices that provide advanced features beyond the capabilities of traditional starters. Some highlights include:

- Soft Starters: Soft starters can gradually ramp up the voltage during motor start and ramp it down during stop. This minimizes stress on the motor and connected equipment, extending their lifespan.

- Variable Frequency Drives (VFDs): VFDs offer precise control over motor speed and can also control torque. They enable energy-efficient operation by adjusting the motor’s speed based on load requirements.

- Intelligent Motor Control Devices: Smart MCCs utilize intelligent motor control devices that not only monitor and protect motors but also communicate essential motor data through a network to PLCs, process control systems, HMIs (Human-Machine Interfaces), or process visualization systems.

Advantages of Smart MCCs:

The capabilities of smart MCCs offer a range of advantages:

- Condition-Based Maintenance: Smart MCCs enable predictive and condition-based maintenance, reducing downtime and maintenance costs by addressing potential issues before they lead to failures.

- Increased System Efficiency: By optimizing motor control parameters and energy usage, smart MCCs enhance overall system efficiency, contributing to energy savings.

- Enhanced Monitoring: The ability to communicate crucial motor data to various systems allows operators and maintenance personnel to stay informed about system conditions and take proactive actions.

- Reduced Wiring and Maintenance Costs: By providing data through networking, the need for extensive contact closures and manual wiring is minimized, reducing both initial setup costs and ongoing maintenance efforts.

- Improved Motor Life: The controlled starting and stopping mechanisms of soft starters and VFDs, along with real-time monitoring, contribute to extended motor life and reduced wear and tear.

In conclusion, smart MCCs bring a paradigm shift in motor control and monitoring by leveraging intelligent devices and networking capabilities. The advantages offered by these advanced systems not only improve operational efficiency but also enable data-driven decision-making, predictive maintenance, and increased overall system reliability.

Energy Consumption and Electric Motors:

The energy consumption of electric motors constitutes a substantial portion of the total energy used in various industries. For instance, process industries in the U.S. account for a significant portion (80%) of the energy used in the industrial sector. Moreover, within these industries, electric motors are responsible for a substantial portion (64%) of energy consumption. Similarly, in other facilities that employ MCCs, the energy consumed by motors remains significant. The cost of operating electric motors, particularly over their operational lifespan, can far exceed their initial purchase price.

Impact on Power Quality:

Electric motors and their associated control devices can have a notable impact on power quality. Poor power quality can lead to detrimental effects on system components, including motors themselves. This can subsequently shorten their operational lifespan and result in higher maintenance costs.

Smart MCCs and Energy Monitoring:

Smart MCCs play a vital role in addressing these challenges through advanced energy monitoring and power quality analysis. Here’s how they contribute:

- Energy Consumption Tracking: Smart MCCs can monitor energy consumption in various ways. This can involve integrating intelligent main circuit breakers, power meters, or power quality meters within MCC sections.

- Data Collection and Communication: The collected energy consumption and power quality data can be communicated through network connections to PLCs, process control systems, and HMI devices or process visualization systems.

- Real-time Monitoring: With real-time access to energy consumption and power quality data, operation and maintenance personnel can stay informed about the system’s performance and efficiency.

- Predictive and Corrective Actions: Armed with this information, personnel can take timely corrective actions to optimize energy usage, address power quality issues, and minimize downtime due to equipment failures.

Benefits of Smart MCCs in Energy Monitoring:

The inclusion of energy monitoring and power quality analysis in smart MCCs offers several benefits:

- Energy Efficiency: Identifying energy consumption patterns and power quality issues enables operators to implement energy-efficient strategies.

- Cost Savings: Proactive measures based on real-time data can lead to reduced energy consumption, lower maintenance costs, and extended equipment life.

- Operational Reliability: Monitoring power quality helps in preventing issues that may negatively impact the lifespan of motors and other system components.

- Data-driven Decision-making: Access to real-time data empowers operators to make informed decisions regarding system operation, maintenance, and optimization.

In essence, smart MCCs not only enhance energy efficiency but also contribute to improved power quality, extended equipment life, and overall system reliability. By providing actionable insights into energy consumption and power quality, these systems enable industries to make strides in sustainability, cost reduction, and operational excellence.

Challenges with Traditional MCCs:

Historically, monitoring the operation of motor control circuits has been challenging due to the inherent complexity of wiring and the cost associated with adding more devices to collect data. While basic information like motor start and overload conditions can be relayed to a PLC, gathering more detailed and useful information becomes increasingly expensive and complex.

Benefits of Smart MCCs:

Smart MCCs revolutionize this landscape by integrating intelligent devices that provide enhanced protection as well as efficient communication of valuable data. Here’s how they overcome the challenges:

- Cost Efficiency: While adding more devices in traditional MCCs can lead to increased costs, smart MCCs incorporate intelligent devices within the MCC structure, reducing the need for extensive additional wiring and associated costs.

- Comprehensive Information: The intelligent devices within smart MCCs are capable of efficiently communicating a wide range of critical information that was previously difficult or costly to obtain. This includes data related to motor conditions, operation, and performance.

- Reduced Complexity: By utilizing intelligent devices and network connectivity, smart MCCs significantly reduce the complexity of wiring and connections, making it easier to gather and transmit information.

- Real-time Communication: The ability of smart MCCs to communicate data in real-time to PLCs, process control systems, and visualization interfaces empowers operators and maintenance personnel with timely and accurate insights.

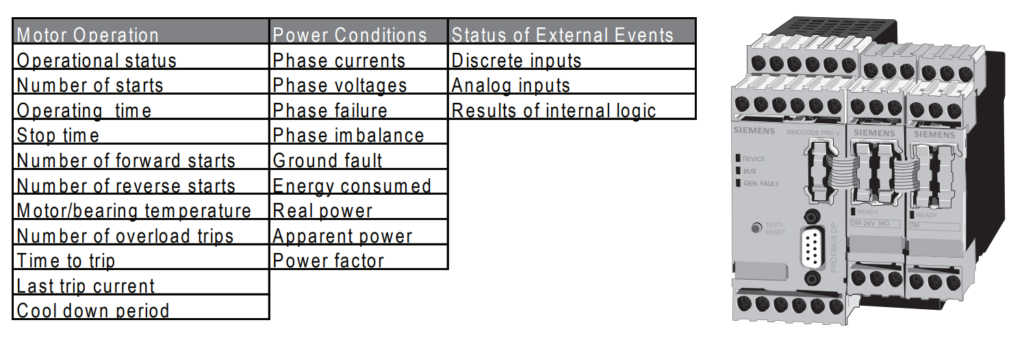

Examples of Information Communication in Smart MCCs:

Here are examples of the types of information that smart MCCs can efficiently communicate:

- Motor Status: Start/Stop, Running, Fault Conditions

- Energy Consumption: Real-time power usage, energy consumed

- Load Conditions: Current draw, torque, speed

- Overload and Protection: Overload trips, overheating alerts

- Power Quality: Voltage fluctuations, harmonics, frequency

- Maintenance Alerts: Predictive maintenance recommendations

- Historical Data: Usage trends, start/stop counts, operating hours

In summary, smart MCCs transcend the limitations of traditional systems by incorporating intelligent devices and streamlined communication capabilities. This transformation enables efficient collection and transmission of vital data, offering comprehensive insights into system operation and motor performance. The enhanced monitoring and communication capabilities of smart MCCs contribute to better decision-making, reduced downtime, improved efficiency, and overall operational excellence.

DIAC the best PLC, SCADA, HMI, Drives, Automation summer training institute offers 6 months Industrial training with blend of theory and practical sessions. Call us : 91- 9953489987.