Non Destructive Testing (NDT), often referred to as NDT testing, is a group of inspection techniques used to evaluate the properties, quality, and integrity of materials and structures without causing any damage to the subject being examined. NDT is widely used across various industries, including manufacturing, construction, aerospace, automotive, and more, to ensure the safety and reliability of components and products.

Key characteristics of NDT include:

- Non-Invasive: NDT methods do not require the alteration or destruction of the tested material or structure. This means that the subject can remain in service or be used for its intended purpose after inspection.

- Versatility: NDT encompasses a wide range of testing methods, each suited for specific applications. Common NDT techniques include ultrasonic testing, radiographic testing, magnetic particle testing, liquid penetrant testing, eddy current testing, and visual inspection, among others.

- Detecting Defects: NDT is used to identify various defects, flaws, or irregularities in materials and structures. These defects can include cracks, voids, inclusions, corrosion, discontinuities, and material property variations.

- Quality Assurance: NDT is a critical tool for quality control and quality assurance processes in manufacturing and construction. It helps ensure that products meet specified standards and are free from defects that could compromise safety or performance.

- Safety: NDT plays a crucial role in assessing the safety of structures and components, such as bridges, pipelines, aircraft, and nuclear reactors. By detecting hidden flaws or wear, NDT helps prevent catastrophic failures and accidents.

Common NDT methods and techniques include:

- Ultrasonic Testing (UT): Uses high-frequency sound waves to detect internal flaws and measure material thickness.

- Radiographic Testing (RT): Involves the use of X-rays or gamma rays to examine the internal structure of materials.

- Magnetic Particle Testing (MT): Detects surface and near-surface defects in ferromagnetic materials using magnetic fields and iron particles.

- Liquid Penetrant Testing (PT): Reveals surface defects by applying a liquid penetrant and developer to the material’s surface.

- Eddy Current Testing (ET): Uses electromagnetic fields to detect cracks, conductivity variations, and material thickness.

- Visual Inspection (VI): Involves a visual examination of the material or structure to identify surface defects and irregularities.

NDT is an essential part of quality control, safety assessment, and maintenance programs in various industries. It helps ensure the reliability and longevity of critical components, reduces the risk of failures, and saves time and resources by avoiding unnecessary dismantling or destructive testing.

Non Destructive Testing:

Non destructive testing (NDT) methods are essential tools for evaluating the quality, integrity, and performance of materials and structures without causing any damage to them. Unlike traditional destructive tests, which can impair the properties of the tested specimens, NDT techniques are non-invasive and are used in various applications, including quality control, failure analysis, and ensuring the reliability of engineered systems.

The field of NDT is broad and interdisciplinary, and it plays a critical role in ensuring that structural components and systems perform their functions reliably. To maintain the reliability of NDT tests and prevent errors, certain standards have been established. These standards help address issues related to equipment faults, method misapplication, and the skills and knowledge of inspectors.

Successful NDT tests are vital for detecting and characterizing material conditions and flaws that could lead to catastrophic failures in various industries, such as aviation, nuclear power, transportation, and manufacturing. However, NDT techniques often require skilled operators, and interpreting test results can be challenging due to the subjective nature of some assessments.

NDT methods can be applied to a wide range of materials, including metals, plastics, ceramics, composites, cermets, and coatings. They are used to identify defects such as cracks, voids, surface cavities, delamination, incomplete or defective welds, and other flaws that could lead to premature failure. While there are universal NDT methods, specific tests have also been developed for unique applications, making NDT a versatile and indispensable field in materials evaluation and structural integrity assessment.

Visual inspection (VI)

Visual inspection (VI) is a highly effective method for identifying macroscopic flaws or defects in various materials and structures. It is particularly useful for detecting issues such as poor welds, which are often visible to the naked eye. Some common macroscopic welding flaws that can be detected through visual inspection include crater cracking, undercutting, slag inclusion, incomplete penetration welds, and more.

Visual inspection is not limited to welding but can also be applied to other components, including composite structures and various types of piping. The approach to visual inspection is similar to how one would inspect a new car before taking delivery. It involves a thorough examination of the material or structure to identify any visible defects or anomalies.

Examples of issues that can be identified through visual inspection include:

- Bad Welds or Joints: Detecting welds that are of poor quality, which can compromise the integrity of the structure.

- Missing Fasteners or Components: Identifying any missing nuts, bolts, or other essential parts that could affect the functionality or safety of the system.

- Poor Fits and Wrong Dimensions: Ensuring that components fit together correctly and have the right dimensions according to specifications.

- Improper Surface Finish: Checking for surface imperfections or irregularities that could impact performance or aesthetics.

- Delaminations in Coatings: Identifying areas where protective coatings have separated or delaminated from the substrate.

- Large Cracks and Cavities: Detecting significant cracks or voids that can compromise structural integrity.

- Dents and Inadequate Size: Verifying that the material or structure is free from dents or is the correct size as required.

- Wrong Parts: Ensuring that the correct components or materials are used in assembly.

- Lack of Code Approval Stamps: Confirming that the necessary quality and safety approvals or stamps are in place.

Visual inspection serves as an essential first step in assessing the condition and quality of materials and structures. It is a valuable tool for identifying visible defects and ensuring that products or systems meet the required standards and specifications.

Radiography

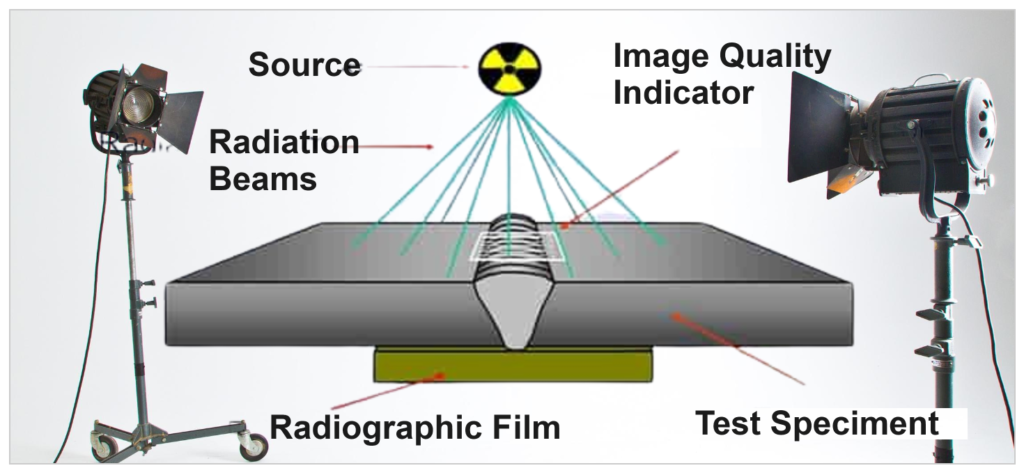

Radiography is a non destructive testing method that offers several advantages, particularly in providing a permanent record of the internal condition of an object being inspected. It is commonly used for assessing the internal soundness of various materials and structures.

Here’s how radiography works and some of its key features:

- Penetrating Ability: Radiography involves the use of X-rays emitted from a source. The ability of these X-rays to penetrate through materials depends on the accelerating voltage in the X-ray emitting tube. Higher voltages result in greater penetration.

- Detection of Voids: When X-rays pass through an object being radiographed, they interact differently with voids or defects within the material. If a void or defect is present, more X-rays will pass through that area, resulting in increased exposure on the film or detector. This differential exposure helps identify the location and size of voids or defects.

- Sensitivity: The sensitivity of X-rays in detecting voids or defects is approximately 2% of the material’s thickness. For example, in a piece of steel with a 25mm thickness, the smallest detectable void would be around 0.5mm in dimension. To ensure thorough inspection, parts are often radiographed from different angles or planes.

- Gamma Radiography: Gamma radiography is a similar method to X-ray radiography in terms of its function. However, it uses a different source of penetrating electromagnetic radiation, which is a radioactive material such as Cobalt-60 (Co-60). This method is less popular due to the hazards associated with handling radioactive materials.

- Permanent Record: One significant advantage of radiography is that it provides a permanent record of the internal condition of the object being inspected. This record can be retained for future reference or quality control purposes.

- Internal Soundness: Radiography is highly effective at detecting internal flaws, voids, or defects in materials, including metals and welds. It allows for a comprehensive assessment of the structural integrity without causing any damage to the object.

While radiography offers valuable insights into the internal condition of materials and structures, it’s essential to follow safety protocols when working with X-ray or gamma radiography due to the potential hazards associated with ionizing radiation. Proper training and safety measures are critical when using these techniques.

Liquid penetrant

Liquid penetrant inspection (LPI) is a widely used non destructive evaluation (NDE) method known for its ease of use and versatility. It relies on the principle of capillary action, where a liquid is drawn into surface-breaking flaws to detect defects. Here’s a breakdown of this method:

- Capillary Action: LPI works by taking advantage of capillary action, where a liquid is naturally drawn into small surface defects or flaws. This allows the liquid to penetrate these flaws, making them visible for inspection.

- Cost-Effective: LPI is considered an economical and convenient technique for inspecting surface defects. It provides an efficient way to identify flaws without the need for complex equipment.

- Surface Inspection: This method is primarily suited for inspecting flaws that break the surface of the sample. It is effective in identifying various types of surface defects, including:

- Fatigue cracks

- Quench cracks

- Grinding cracks

- Overload and impact fractures

- Porosity

- Laps and seams

- Pinholes in welds

- Lack of fusion or brazing along bond lines

- Materials Inspected: LPI is commonly used for inspecting a range of materials, including metals (such as aluminum, copper, steel, titanium), glass, various ceramic materials, rubber, and plastics. It is especially valuable for non-magnetic materials where magnetic particle inspection is not applicable.

- Subsurface Limitation: One limitation of LPI is its inability to detect subsurface flaws. It is primarily designed for surface defect inspection. If subsurface defects are suspected, other NDE methods like radiography or ultrasonic testing may be more suitable.

- Resolution on Porous Materials: LPI may experience a loss of resolution when applied to porous materials, as the liquid may be absorbed into the material, affecting the inspection results.

Liquid Penetrant Procedure

The liquid penetrant method is a non destructive testing technique used to detect surface defects in materials. Here’s an explanation of the steps involved in this method:

Surface Preparation:

- Cleaning: Ensure that the surfaces to be inspected are completely free from any coatings, paint, grease, dirt, dust, or other contaminants. Clean the surface using an appropriate method, such as alcohol. Be careful not to damage the original surface during cleaning, as this can affect the accuracy of the inspection.

- Drying: After cleaning, allow the surface to dry for about 2 minutes to ensure there is no residual moisture.

Application of Liquid Penetrant:

- Apply Penetrant: Use commercially available liquid penetrant dyes in aerosol cans with different colors designed to reveal surface defects. Apply the liquid penetrant spray (usually in a red can) evenly to the surface to be inspected. Brushing may be necessary to aid penetration. Allow the penetrant to sit on the surface for a specified duration, typically around 20 minutes. During this time, the penetrant will seep into any surface defects.

Removal of Excess Penetrant:

- Remove Excess Penetrant: After the penetration time has passed, wipe the surface with a clean cloth or textile to remove excess penetrant. This step helps in preventing false indications during the subsequent inspection.

Application of Developer:

- Apply Developer: Spray the developer (typically in a yellow can) onto the surface from a distance of approximately 30 centimeters. The developer absorbs the penetrant that has infiltrated the surface defects, creating a visible indication. The developer forms a geometric shape that is the negative of the surface defect geometry from which the penetrant was drawn.

Evaluation and Documentation:

- Inspect and Collect Data: Examine the surface for any indications or defects revealed by the developer. These indications will appear as visible patterns on the surface where penetrant was drawn into defects. The size and shape of the indications can provide information about the nature and extent of the defects.

- Collect Polymerized Material: If needed, the polymerized material from the developer may be collected on a sticky paper for future evaluation and documentation.

The liquid penetrant method is an effective way to detect surface flaws, cracks, splits, or other defects that may not be visible to the naked eye. It is commonly used in various industries to ensure the quality and integrity of materials and components.

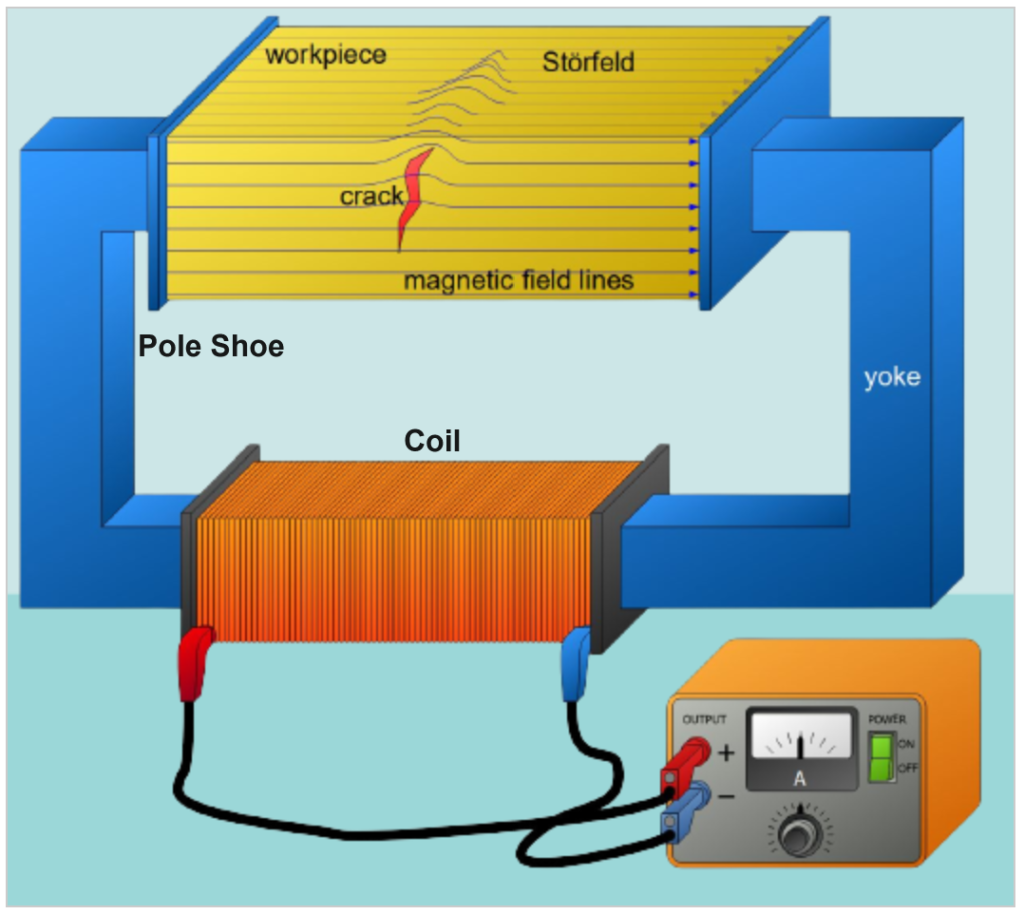

Magnetic particles:

Magnetic particle inspection is a widely used non destructive testing method known for its simplicity, speed, and cost-effectiveness. It is particularly valuable for detecting flaws in components made of ferromagnetic materials like iron, nickel, cobalt, and their alloys. Here’s an overview of how this method works:

- Materials Requirement: Magnetic particle inspection is most effective when applied to ferromagnetic materials, which can be magnetized to a level suitable for inspection. Many engineering materials, including structural steels, fall into this category, making the method applicable to a wide range of industries.

- Basic Setup: The inspection process typically involves the following steps:

- An electromagnet yoke is placed on the surface of the component under examination.

- A suspension of iron particles (often mixed with kerosene or oil) is applied to the surface of the part.

- The electromagnet is energized, creating a magnetic field in the component.

- Flaw Detection: When a flaw, such as a crack or defect, is present on the surface of the component, it disrupts the flow of magnetic flux. This disruption causes the formation of new south and north magnetic poles at each edge of the flaw. Just like iron particles scattered on a cracked magnet, the iron particles in the suspension are attracted to and cluster at the pole ends created by the flaw. This clustering of particles is much more visible than the actual flaw itself, making it the basis for flaw detection.

- Optimal Sensitivity: To achieve the best sensitivity and detection results, it is essential that the lines of magnetic force are perpendicular to the defect. This orientation ensures that the magnetic field interacts effectively with the flaw, leading to the clustering of iron particles for easy visual identification.

Magnetic Particle Procedure:

The magnetic particle testing method is a non destructive testing technique used to detect surface and near-surface defects in ferromagnetic materials. Here are the steps involved in this method:

Materials and Equipment:

- Commercially available magnetic powder designed for non destructive testing (NDT) inspection.

- A strong U-shaped magnet to provide the necessary magnetic field.

- A piece of textile or cloth for surface cleaning.

- A fluorescent magnetic spray.

- UV light for inspection.

Procedure:

- Surface Cleaning: Begin by roughly cleaning the surface of the specimen using a piece of textile or cloth. The goal is to remove any loose dirt or debris from the surface.

- Application of Magnetic Powder: Apply the fluorescent magnetic spray evenly to the surface being inspected. The magnetic powder in the spray is designed to adhere to any magnetic flux leakage caused by surface defects.

- Application of Magnetic Field: Use the strong U-shaped magnet to apply a magnetic field to the specific area of interest on the specimen. The magnetic field helps attract the magnetic particles to any defects or anomalies in the material.

- Particle Accumulation: As the magnetic field is applied, the fluorescent magnetic particles will accumulate at areas where there are surface defects or disruptions in the magnetic field caused by internal defects. These areas will become visible due to the accumulation of particles.

- UV Inspection: Inspect the surface under UV (ultraviolet) light. The fluorescent magnetic particles will fluoresce or emit light when exposed to UV light. This fluorescence highlights the areas where particles have accumulated, indicating the presence of defects.

- Defect Identification: Examine the illuminated areas for indications or patterns of fluorescent particles. These indications represent the locations of surface and near-surface defects in the material. The size and shape of these indications can provide information about the nature and extent of the defects.

Magnetic particle testing is widely used for detecting defects such as cracks, surface discontinuities, and other irregularities in ferromagnetic materials. It is a valuable tool in industries like manufacturing, aerospace, automotive, and construction to ensure the structural integrity of components and materials.

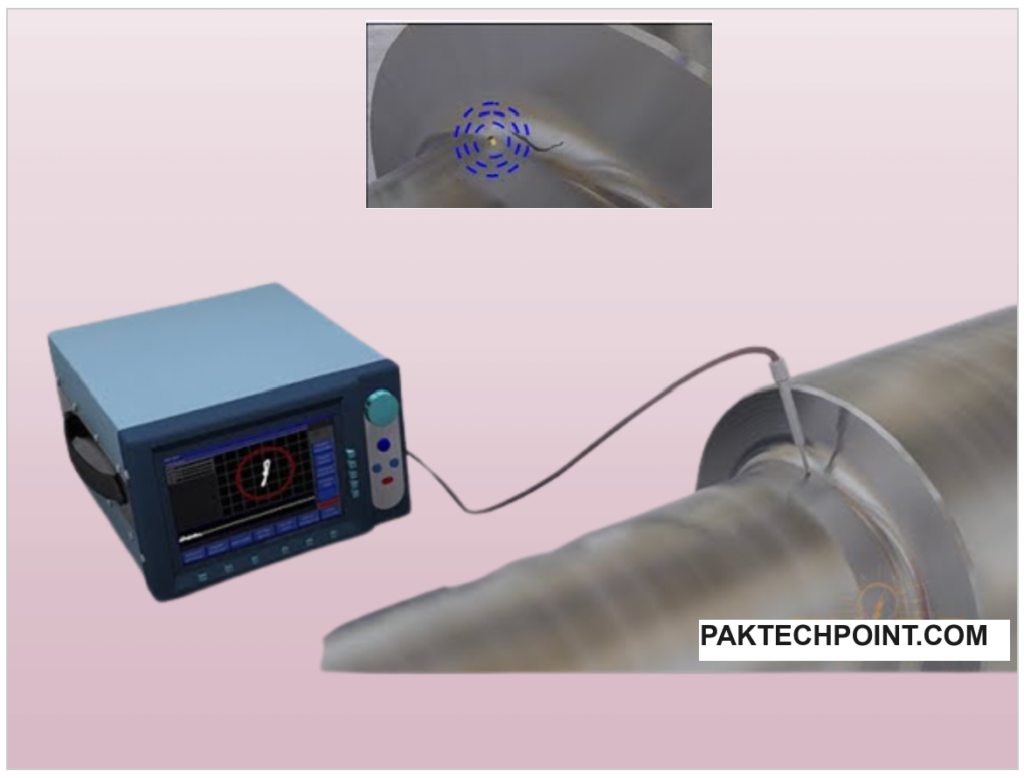

Eddy current testing

Eddy current testing is a non destructive testing method based on the principles of electromagnetic induction.

Here’s how it works:

- Electromagnetic Induction: Eddy currents are generated through the process of electromagnetic induction. When an alternating current (AC) is applied to a conductor, such as a copper wire, it creates a magnetic field around the conductor. This magnetic field expands and collapses as the AC current cycles.

- Induction in Nearby Conductor: When another electrical conductor is brought into close proximity to this changing magnetic field, it induces current in the second conductor. These induced currents are known as eddy currents.

- Sensing Probe: In practical applications, a sensing probe is placed on the surface of the object being inspected. The probe contains a coil that generates the alternating magnetic field and a second coil that serves as a sensor to detect the eddy currents induced in the object.

- Material Influence: The behavior of the eddy currents is influenced by various factors, including the material’s properties, such as voids, cracks, changes in grain size, and the physical distance between the coil and the material.

- Applications: Eddy current testing is versatile and can be used for various purposes, including:

- Crack detection

- Measurement of material thickness

- Measurement of coating thickness

- Conductivity measurements for material identification

- Detection of heat damage

- Determination of case depth

- Monitoring heat treatment processes

Advantages:

- High sensitivity to small cracks and defects.

- Can detect surface and near-surface defects.

- Provides immediate results.

- Portable equipment, suitable for various applications.

- Requires minimal part preparation.

- No need for physical contact with the inspected part.

- Suitable for inspecting complex shapes and sizes of conductive materials.

Limitations:

- Applicable only to conductive materials.

- Requires an accessible surface for probe placement.

- Requires trained personnel for operation.

- Surface finish and roughness can interfere with results.

- Needs reference standards for setup and calibration.

- Limited depth of penetration.

- Cannot detect flaws that are parallel to the probe coil winding and scan direction.

Eddy current testing is a valuable non destructive testing method used in industries where the inspection of conductive materials is critical for safety and quality assurance.

Eddy current Procedure

Eddy current inspection is a non destructive testing method that uses electromagnetic induction to detect flaws and irregularities in conductive materials. Here are the steps involved in this method:

Materials and Equipment:

- Eddy current inspection unit (e.g., Magnefest ED-510)

- Pencil-type probe for inspections

- Test blocks or specimens prepared for the experiment

- Surface cleaning materials (to remove coatings or paints)

- Calibration settings, including frequency (2 MHz)

Procedure:

- Prepare the Inspection Area: Ensure that the inspection area is clean, smooth, and free from any irregularities, coatings, paint, dirt, grease, or other contaminants. The surface should be in a suitable condition for inspection.

- Visual Inspection: Visually inspect the specimen for any visible damage or discontinuities before starting the eddy current inspection. Ensure that there are no obvious defects that could interfere with the inspection process.

- Probe Calibration: Position the probe near the inspection area on the compensation point. Adjust the lift-off and zero settings on the eddy current inspection unit as necessary to ensure accurate readings during the inspection.

- Probe Scans: Perform the inspection by using probe scans over the surface of the specimen. Keep the probe tip at a right angle to the inspection surface to maintain consistency during scanning.

- Indication Evaluation: Pay attention to the readings on the inspection unit’s indicator. If the indicator deflects to the right or shows any significant change, evaluate these indications. All evaluated indications should be carefully measured to assess their size and nature.

- Indication Recording: Record and document all evaluated indications with indicator deflections. These indications are potential anomalies or defects that may require further examination or analysis.

- Crack Classification: After the inspection procedure, classify and record all evaluated indications that are considered as cracks. These cracks should be clearly identified and documented for further action or analysis.

Eddy current inspection is commonly used to detect surface and near-surface defects, cracks, voids, and material discontinuities in conductive materials. It is widely applied in industries such as aerospace, automotive, manufacturing, and quality control to ensure the integrity of components and materials.

Ultrasonic Testing (UT)

Ultrasonic Testing (UT) is a non destructive testing method that utilizes high-frequency sound energy to inspect materials for various purposes, including flaw detection, dimensional measurements, and material characterization. Here’s how it works:

Components of UT Inspection:

- Pulser/Receiver: An electronic device that generates high-voltage electrical pulses.

- Transducer: A device that produces high-frequency ultrasonic energy based on piezoelectricity, typically using materials like quartz, lithium sulfate, or ceramics. Frequencies range from 1 to 25 MHz.

- Display Devices: Instruments used to visualize and interpret the results of ultrasonic inspections.

Working Principle:

- Generation of Ultrasonic Waves: The pulser sends high-voltage pulses to the transducer, which converts this electrical energy into high-frequency ultrasonic waves.

- Transmission through Materials: These ultrasonic waves are introduced into the material under inspection. Common couplants like water, oil, glycerin, or grease are used to facilitate the transmission of ultrasonic waves from the transducer to the test piece.

- Wave Reflection: The ultrasonic waves propagate through the material until they encounter an interface, such as the opposing surface of the material or an internal defect like a crack or void.

- Defect Detection: When the ultrasonic waves encounter an internal defect, they are interrupted, and a portion of the wave is reflected back toward the transducer.

- Measurement: The amplitude of the reflected energy and the time it takes for the wave to return provide information about the presence and location of flaws or defects within the material.

Advantages of Ultrasonic Inspection:

- High sensitivity to both surface and subsurface discontinuities.

- Excellent depth of penetration for detecting flaws or taking measurements.

- Single-sided access is possible for the pulse-echo technique.

- High accuracy in determining the position, size, and shape of reflectors.

- Minimal part preparation required.

- Provides instantaneous results using electronic equipment.

- Detailed imaging can be achieved with automated systems.

- Suitable for various applications, including thickness measurements.

Limitations of Ultrasonic Inspection:

- Requires an accessible surface for sound transmission.

- Skilled and trained personnel are necessary to perform and interpret inspections.

- Coupling medium (e.g., water or oil) is needed for sound energy transfer.

- Limited applicability for rough or irregular surfaces, small parts, varying thickness, or non-homogeneous materials.

- Challenging to inspect coarse-grained materials due to low sound transmission and high signal noise.

- Linear defects must be oriented parallel to the sound beam for detection.

- Calibration of equipment and the characterization of flaws require reference standards.

Ultrasonic inspection is a versatile and powerful non destructive testing method commonly used in industries where accurate flaw detection and material assessment are essential for safety and quality assurance.

Ultrasonic Test Procedure:

Ultrasonic inspection is a non destructive testing method that uses high-frequency sound waves to detect internal flaws and discontinuities in materials. Here are the steps involved in this method:

Materials and Equipment:

- Ultrasonic unit (e.g., USM-2) with a frequency of 5 MHz

- Test blocks or specimens

- Couplant (suitable for the application and material)

- Calibration settings and reference standards

Procedure:

- Prepare the Inspection Area: Ensure that the inspection area is clean and free from any contaminants or irregularities that could affect the ultrasonic inspection process.

- Instrument Tuning: Set the ultrasonic unit to the appropriate frequency for the inspection, which, in this case, is 5 MHz. Ensure that the instrument is correctly tuned to the chosen frequency.

- Apply Couplant: Apply a sufficient amount of couplant to the transducer scan areas on both the forward and rear sides of the support fitting. The couplant is essential for the transmission of ultrasonic waves into the material being inspected. It should not cause corrosion or damage to the material.

- Calibration: If necessary, perform calibration on the reference standard to ensure the accuracy of the ultrasonic unit. Calibration helps establish a baseline for signal interpretation.

- Probe Placement: Depending on the shape of the specimen:

- For circular test specimens, place the probe in the corresponding space within the supporting fitting tool. Ensure that an adequate amount of couplant is used between the probe and the tool.

- For flat specimens, no additional tool is needed. Apply couplant directly between the inspected surface and the probe.

- Identify Potential Crack Locations: Pay special attention to areas where possible cracks or defects are suspected or known to exist within the specimen.

- Monitor the Display: As you perform the ultrasonic inspection, monitor the display of the ultrasonic unit. When a discontinuity such as a crack is encountered, it will produce a peak or signal on the screen.

- Analyze Peak Movement: Take note of the movement of the detected peak caused by the presence of cracks within the specimen. This information can help in assessing the nature, size, and location of the discontinuity.

Ultrasonic inspection is a powerful method for detecting internal flaws, cracks, and discontinuities in materials, including metals and composites. It is commonly used in various industries, including manufacturing, aerospace, and quality control, to ensure the integrity and safety of components and structures. The accuracy of the inspection results depends on proper calibration and skilled interpretation of the signals displayed on the instrument.

Differences between Radiography testing & Ultrasonic testing:

| Radiography testing | Ultrasonic Testing |

| Hazardous to personnel: need human clearance from site & causes interruption to production. | Non-Hazardous. |

| Require access to two side of the component in order to carry out test | Requires access to only one side of the component to carry out test. |

| Not suitable for weld with complicated geometry | Suitable for weld with all possible geometry. |

| Relatively expensive | Cheaper when compared with Radiography test. |

| Require only medium level of personnel training & capability | Require a higher level of operator training & capabilities |

| Produce permanent record of the test, which reduce the need for operator integrity | Manual U.T provides no permanent record of the test & it is highly dependent on the operator’s integrity |

| Radiograph is easy to interpret | Records produced by automated system may not be straight forward. |

| High sensitivity to volumetric defects. | Reasonable sensitivity to volumetric defects. |

| Variable sensitivity to planar defects | High sensitivity to planar defects. |

| Gives two dimensional views of the defect size & its position. | Gives accurately 3-dimensional information about the defect. |

| Applicable to all metals & alloys irrespective of their grain structure | Applicable to steel & alloys with fine grain structure & which are homogenous. |

| Doesn’t require a high degree of surface preparation | Require a high degree of surface preparation |

| Can test upto 300mm of ferritic steel. | Can test upto 10,000mm or more of ferritic steel. |

DIFFERENCES BETWEEN DYE PENETRATION TEST & MAGNETIC PARTICLE TEST.

| MAGNETIC PARTICLE TEST | DYE PENETRATION TEST |

| Low inspection cost & rapid inspection rate | Lower equipment cost & take more time |

| Applicable only to Ferro-magnetic materials | Applicable to all metals & alloys |

| Very good sensitivity to small defect | Reasonable sensitivity to small defects in all non-porous materials |

| Capable of detecting surface & near surface defects (upto 3mm) | Capable of detecting only surface defects |

| Requires moderate level of surface preparation | Require high level of surface preparation & surface must be smooth. |

| Applicable on wide range of temperature. | Applicable over a limited range of temperatures. |

| Chances of surface burning if using prods | No chance of surface burning. |

| Instant results | Result take developing time |

| Chances of electric shocks | No power required |

| Can’t be done on all positions | Can be done on all positions. |

MCQ IMPORTANT POINTS:

- In Radiography test if source is X-Rays then penetration power depends on voltage applied.

- In Radiography test if source is γ-Rays then penetration power depends on type of Isotope.

- R.T can be used upto a thickness of 300mm of steel.

| γ-Rays Source | Range of thickness |

| THULIUM-90 | UPTO 7mm |

| YTTERBIUM-169 | 7-12mm |

| IRIDIUM-192 | 10-75mm |

| COBALT-60 | 40-150mm |

Some Important technical points for engineers to keep in mind.

- R.T has high sensitivity for volumetric defects.

- R.T has low sensitivity for planar defects.

- Ultra-sonic test is not applicable on Austentic Stainless Steel & Manganese Stainless Steel.

- PIEZO-ELECTRIC EFFECT: Conversion of electric energy in mechanical energy & vice-versa.

- Laminations are best detected by U.T test.

- Planar defects are best detected by U.T test.

- Surface preparation is required in U.T test.

- U.T test require only one side access of material.

- U.T can scan upto a depth or thickness of 300mm.

- Magnetic Particle Testing is applicable only on Ferro-magnetic materials

- Fluorescent Magnetic Particle Test has high sensitivity & can be done in where visibility is poor.

- Defects should be perpendicular to magnetic field for detection

- CURIE TEMPERATURE: It is the temperature at which the material losses its magnetic property & the temperature is 650 degree centigrade.

- M.P.T can detect defects upto 3mm.

- Dye-Penetration Test is used to detect open to surface defects.

- Principle of D.P.T is capillary action of penetrant.

- Fluorescent Penetration test has high sensitivity.

- D.P.T is not applicable on porous material.

- Developer will help in Bleed-out Process.