The concept of Total Dynamic Head (TDH) is indeed crucial in understanding the energy requirements for moving water within a fluid system, particularly in the context of pumps. As mentioned in the provided definition, TDH represents the total energy needed to transport water from one point to another, taking into account various factors.

What is Total Dynamic Head?

Let’s break down the components mentioned in the definition:

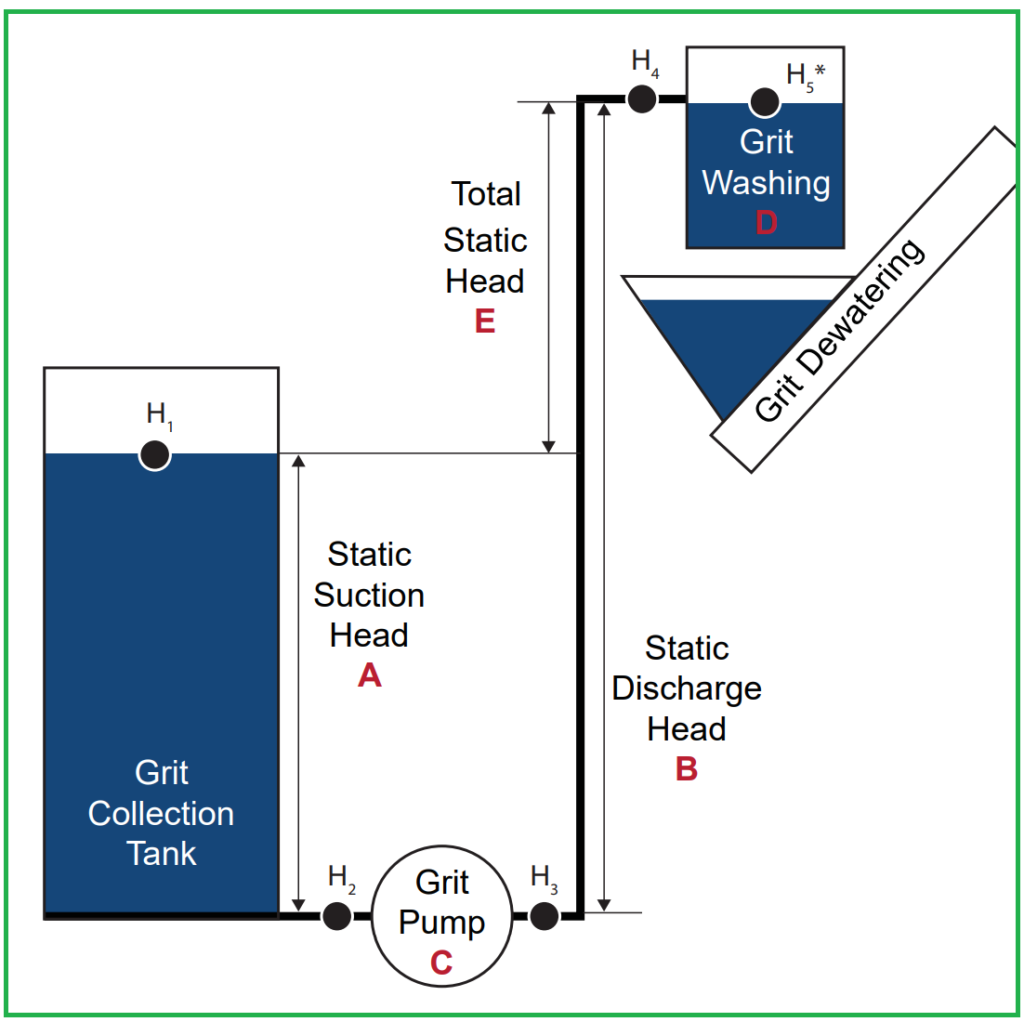

- Static Head: Static head refers to the elevation difference between the water source (inlet) and the destination (outlet) point in the system. It accounts for the potential energy change due to the difference in height. The static head is essentially the vertical distance that the pump needs to lift water or how high the water needs to be pushed to reach a certain point.

- Velocity Head: Velocity head represents the kinetic energy associated with the movement of water. It accounts for the energy required to accelerate and maintain the flow of water through the pipes and components of the system. It is calculated based on the fluid’s velocity and is often expressed as (V^2) / (2g), where “V” is the velocity of the fluid and “g” is the acceleration due to gravity.

- Head Loss due to Friction: As water flows through pipes, fittings, valves, and other components in the system, it encounters resistance, resulting in friction losses. These losses reduce the energy available for actual work. The head loss due to friction is a measure of this resistance and is calculated using various formulas, including the Darcy-Weisbach equation or the Hazen-Williams equation, depending on the type of fluid and the characteristics of the piping.

TDH is a crucial parameter for pump selection and system design because it represents the total energy requirement to move water through the entire system. Engineers and pump operators need to ensure that the selected pump is capable of providing the necessary energy to overcome the static head, velocity head, and head losses due to friction to achieve the desired flow rate and pressure at the destination.

By accurately calculating TDH and understanding its components, engineers can choose the right pump for a given application, operate pumps efficiently, and optimize the performance of fluid systems, whether in water supply, industrial processes, or other applications where pumps are used.

Total Dynamic Head (TDH) Formula:

Total Dynamic Head (TDH) is a critical concept in fluid mechanics and is commonly used in the design and analysis of pumping systems. It represents the total energy head or pressure head required to move a fluid (such as water) from the source to its destination through a piping system. TDH is a sum of three main components:

- Total Static Head (TSH): This component represents the vertical distance between the water source (e.g., a well, reservoir, or tank) and the point where the fluid needs to be delivered, usually measured in feet or meters. TSH accounts for the elevation difference or height the fluid needs to be lifted against gravity.

- Friction Loss (FL): Friction loss occurs as the fluid flows through pipes, fittings, valves, and other components within the piping system. It is caused by the resistance of the pipe walls to the flow of the fluid and is influenced by factors such as pipe diameter, length, roughness, and the velocity of the fluid. Friction loss is typically calculated in terms of head (feet or meters).

- Head at the Washing Unit (HWU): This component represents any additional head or pressure required at the point of use, such as a washing unit, to overcome specific requirements like pressure for spray nozzles, valves, or any other equipment within the system.

The formula you provided, TDH = TSH + FL + HWU, accurately describes how the Total Dynamic Head is calculated. In practical terms, TDH helps engineers and designers determine the necessary specifications for a pump to ensure it can overcome the total resistance (static head, friction losses, and additional head requirements) and deliver the required flow rate at the desired pressure to meet the system’s demands.

Here we took example of grit pump system.

By calculating TDH accurately, it becomes possible to select an appropriate pump that can handle the specific conditions of a pumping system and provide the required performance while considering factors such as flow rate, pump efficiency, and power consumption.

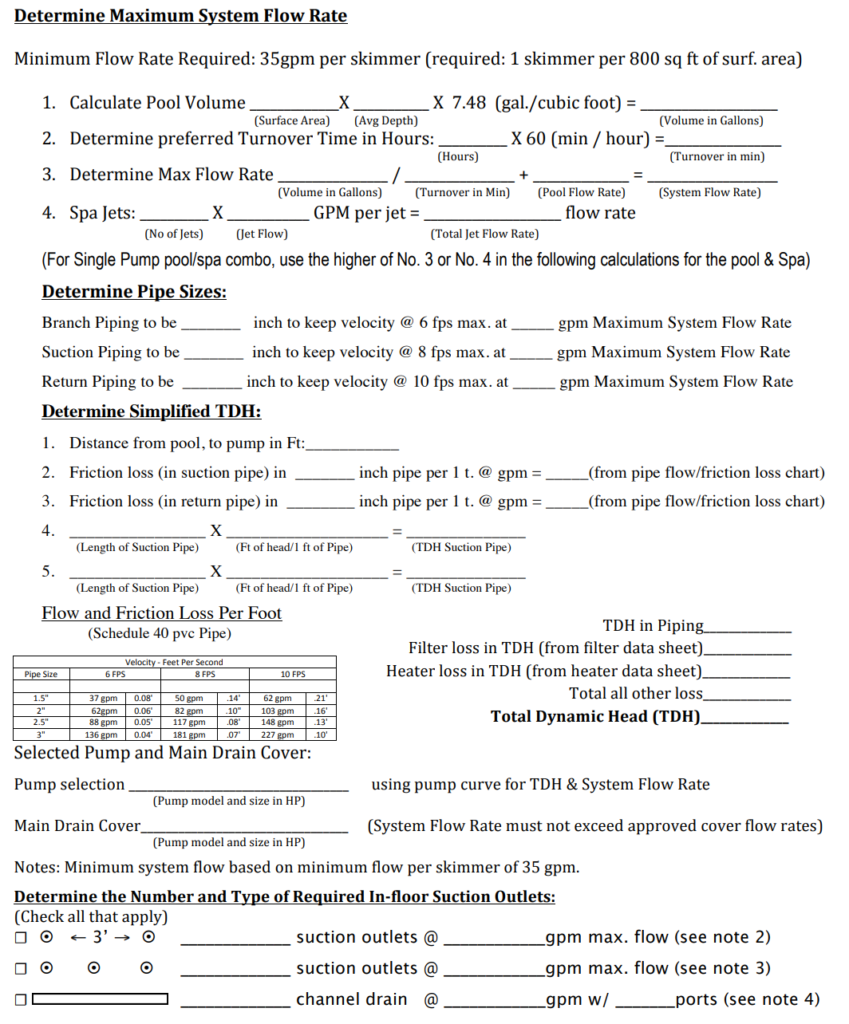

Total Dynamic Head (TDH) Calculation Worksheet