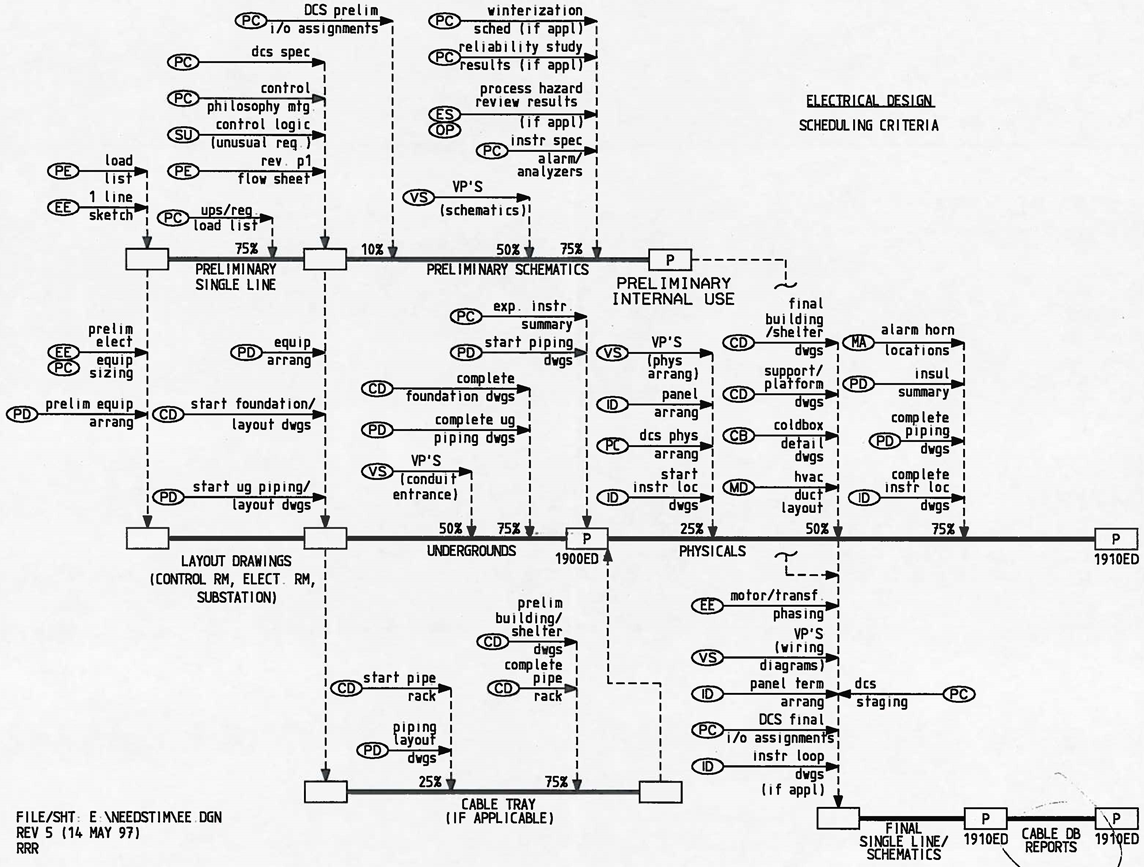

This article is about Electrical Design Work Procedure related to topic of Electrical Design as per International Codes & Standards. Here furthermore will be discussed about Electrical System Design Pdf,

Electrical Installation Design Guide, Electrical Design Process of Construction Project in Plant and Petrochemical Plants.

1. PURPOSE – This article is about identifies the process and procedures for executing an electrical plant or process design to meet project deliverables for client.

2. SCOPE

2.1 This article applies to all members of the Electrical Design Group of Plant Design Engineers, and serves as the basis for the process that will be used to execute a successful opportunity. This article is meant to be general in nature and it is the responsibility of the Lead Electrical Designer, which parts of this work instruction are applicable to each specific opportunity.

3. RESPONSIBILITY

3.1 Normally, The Lead Electrical Designer is responsible for determining any special customer requirements for each opportunity.

3.2 The Supervisor, Electrical/Instrumentation Design is responsible for auditing compliance to this procedure.

4. Electrical Design Work Procedure | Electrical Design Process

4.1 Pre “Design Start” Process

4.1.1 First, Obtain the Preliminary Plant Single Line sketch and Preliminary Load List from the assigned Electrical Engineer and create the electronic CAD files. These files should be marked as preliminary in the CAD file title block and watermarked as preliminary.

4.1.2 Obtain the Preliminary Plant Equipment Arrangement drawing from Plant Design and review for adequate spacing between electrical equipment and consistency of equipment arrangement.

4.2 Electrical Design Documentation Requirements

-

-

- At the start of an active project, the assigned Lead Electrical Designer shall assemble and/or create the following information as well as any special documents or actions determined necessary.

- Acquire the Project Number (Format ENXXYYYY) and Project Charge Number from the assigned Project Manager or Project Development Engineer.

- You need to Request opportunity security permissions in the document storage system from the assigned Project Technician.

- Request document access permission for opportunities involving outside A&E firms or other Engineering Centers from the assigned Project Technician.

- Verify the project Computer Aided Design (CAD) folder has been created on the appropriate CAD server. Normally Folder title format uses the last 5 digits of the project number; Ex. XYYYY. If the folder does not exist contact the CAD services group to create the folder.

- Verify Units of Measure (UOM) to be used on the opportunity from the assigned Project Manager or Project Development Engineer.

- Fill out the Design Standards Checklist, table given in this article Standards for Electrical and Instrument Design, to identify the electrical standards that will apply to the opportunity. This checklist will also be used to generate the list of standards to be sent with the Electrical Construction package.

- Obtain a copy of the Approved for Design P&ID flow sheets from the assigned Systems Engineer. Highlight all elements on the P&ID pertaining to the electrical design effort.

- Obtain a copy of the Approved for Design General Arrangement drawing the assigned Project Manager or Project Development Engineer.

- Obtain a copy of the Approved for Design Equipment General Arrangement drawing the assigned Project Manager or Project Development Engineer.

- Get a copy of the approved for design Shutdown tables from the assigned Process Systems Engineer and the approved for design I/O List from the assigned Process Controls Engineer.

- Assemble vendor documents and drawings from the document storage system for those electrical items identified on the P&IDs, load list, and single line diagram. If the document or drawing does not exist in the document storage system contact the appropriate discipline to obtain the required information.

-

4.3 Document Creation and Storage

-

-

- Once the project information has been identified the Lead Electrical Designer shall begin to create the project deliverables. All produced project deliverables shall be stored in the document storage system and related to the Plant wide assembly under the Opportunity.

- All electronic CAD drawings and documents shall be produced under the CAD server folder created for the opportunity and stored in the document storage system in both electronic format (Microstation dgn or Autocad dwg) and image file format (tif or pdf).

- When multiple documents of the same type; i.e. Medium Voltage Control Schematics, are required the designer shall maintain the same document number and give each unique document its own sheet number.

- The Lead Electrical Designer shall perform a thorough review of the for design P&IDs and Finalized Load List to recognize areas where electrical controls may be required of equipment not specified by the Electrical or Machinery disciplines. When these areas are identified the Lead Electrical Designer shall communicate with the responsible discipline to determine what electrical design efforts are required to incorporate these requirements into the overall design. Some examples of where the Lead Electrical Designer may encounter these issues are with the TSA Heater Controls, Oily Water or Process Waste Sump systems, site erected building heating and ventilation, etc.

-

4.4 Electrical Project Deliverables (Electrical Deliverables List)

4.5 Special Request Documents

These document types are usually a special request by the customer and shall be verified as required by the project manager.

4.5.1 Loop Drawing documents – Create using Standard Deliverable STD-DELIV INST 0023 SH.01 from the document storage system.

Drawing content requires the I/O list, load list, vendor supplied Electrical Equipment data, Project P&IDs and information generated during the design effort.

4.5.2 AC Three Line Drawing documents – Create using Standard Deliverable STD-DELIV ELEC 0040 from the document storage system.

Drawing content requires the I/O list, load list, single line, vendor equipment data, and information generated during the design effort.

4.6 Facility Change Notice (FCN)

4.6.1 During project execution changes to the design effort will be in the form of a Flowsheet or Facility Change Notice (FCN). The Lead Electrical Designer shall review the changes and evaluate any implications or modifications to the electrical design effort. Once the changes have been reviewed, the effected documents shall be retrieved from the document storage system, a hardcopy of the documents shall be red lined, and the required changes made to the electronic files. The revised documents shall be checked and approved according to the Appendix B approval matrix.

4.7 Issuing the Electrical Design Package for Bid/Construction

4.7.1 The Project Technician assigned to the opportunity is responsible for creating the “Package” in the document storage system. Once the package has been created it is the responsibility of the Electrical Designer to populate the package with the documents created during the design effort and the appropriate standards and standard drawings.

4.7.2 As Electrical Engineer / Designer can use this article Standards for Electrical and Instrument Design to determine which standards and standard drawings and table 1 given below along with the Drawing Index document to determine which electrical design documents to include in the Bid or Construction package.

4.7.3 It is the responsibility of the Electrical Designer to include the electrical equipment commissioning standards in the Bid or Construction package. The Electrical Designer shall consult with the electrical engineer as to which commissioning standards to include in the package. Here check all article related to electrical commissioning Electrical Equipment Commissioning, Commissioning: Low-Voltage Distribution Systems | MCC and Commissioning: Low Voltage Power and Control Distribution Equipment shall be included the Bid or Construction package.

4.8 Revision Marking

4.8.1 Construction Revision

-

- After initial drawing “Release for Construction” and requiring a change which affects its content, the drawing shall be raised to the next revision level in the document storage system. The content affected by the change shall be accurately “clouded” to clearly indicate the changed portions. Revision “clouds” shall be placed so as not to obscure drawing content. Multiple “clouds” may be placed per revision to include all areas affected by the change. A revision “triangle”, incorporating the current revision number, shall be placed inside the border of each “clouded” area. A brief written description to identify the details of the change shall be incorporated into the revision block with the corresponding revision number and appropriate date and signatures. If changes are too numerous to include in the written description, “Revised as indicated” in the revision block shall be acceptable.

- Subsequent revisions shall be executed as above, but previous revision “clouds” shall be removed from the drawing. Previous revision “triangles” shall remain on drawing. In a case where all the revision block lines have been filled, contents of the earliest revision line shall be removed from the drawing, with the remaining content being lowered to allow a blank line at the top of the revision block for the insertion of the new current revision line.

4.8.2 AS-Built Revision

-

- Upon completion of the construction execution phase, the contractor or Air Products technician shall provide documented “red-marked” changes to represent “as-built” conditions. These changes shall be incorporated into drawings by the assigned electrical designer. All previous revision “clouds” and “triangles” shall be removed from the drawing to signify “as-built” conditions. The revision block shall include the text “AS-BUILT” along with corresponding revision number and appropriate date and signatures. A drawing shall only be brought to “as-built” status, if field changes were made to the drawing.

Appendix A

Standards for Electrical and Instrument Design

Appendix B

| DOCUMENT | CONSTRUCTION PACKAGE | CHECKED BY | APPROVED BY | NOTIFICATION |

| Drawing Index | YES | EIDS | ||

| Facility Key Plan and General Notes | YES | EIDS | PM, PDE | |

| Medium Voltage Single Line Diagram | YES | EE | EIDS | PM, PDE |

| Low Voltage Single Line Diagram | YES | EE | EIDS | PM, PDE |

| Medium Voltage (>1000 volts) Control Schematic | YES | EE | EIDS | |

| Low Voltage AC Equipment (>240 volts and <1001 volts) Control Schematics | YES | EE | EIDS | |

| Low Voltage AC Equipment (<241 volts) Control Schematics | YES | EE | EIDS | |

| Low Voltage 24VDC Control Schematics | YES | PCE | EIDS | |

| Low Voltage Panelboard Schedules | YES | EIDS | ||

| Underground Grounding Grid document(s) | YES | EE | EIDS | |

| Underground Conduit document(s) | YES | EIDS | CE | |

| Cable tray Layout document(s) | YES | EIDS | PM, PDE, PD | |

| Lighting and Utility Plan document(s) | YES | EIDS | ||

| Heat Trace Schedule document(s) | YES | EIDS | ||

| Terminal Box Tabulation document(s) | YES | EIDS | ||

| Control/Junction Box Fabrication document(s) | PCE | EIDS | ||

| AC Interconnect Wiring Diagram document(s) | YES | EIDS | ||

| DC Interconnect Wiring Diagram document(s) | YES | EIDS | ||

| AC Power and Control Cable Schedule document(s) | YES | EIDS | ||

| DC Power and Control Cable Schedule document(s) | YES | EIDS | ||

| Building Plan Detail document(s) | YES | By Discipline | EIDS | |

| Plant Plan and Details document(s) | YES | EIDS | ||

| Plant Bill of Material document(s) | YES | EIDS | ||

| Electrical Equipment Connection document(s) | YES | EE | EIDS | |

| Hazardous Area Classification Drawing document(s) | PS | Saf | PM, PDE | |

| Fiber Optic Cable Details document(s) | YES | By Discipline | EIDS | |

| Medium Voltage Motor/Transformer Phasing document(s) | YES | EE | EIDS | |

| High Voltage Cable Design Form document(s) | EE | EIDS | ||

| High Voltage Cable Order Form document(s) | EE | EIDS | ||

| High Voltage Cable, Project Transmittal Requisition document(s) | EIDS | |||

| Terminal Lug Order Form document(s) | EE | EIDS | ||

| Termination Kit Order Form document(s) | EE | EIDS | ||

| Project Transmittal Requisition – Terminal Lugs and Termination Kits document(s) | EIDS | |||

| Loop Drawing document(s) | PCE | EIDS | ||

| AC Three Line Drawing document(s) | EE | EIDS |

EIDS – Electrical and Instrument Design Supervisor, EE – Electrical Engineer, PCE – Process Controls Engineer, PM – Project Manager/Engineer, PDE – Process Development Engineer, CE – Civil Engineer, PD – Piping Designer, Saf – Safety.

By Discipline – Choose the appropriate discipline to check/approve the document.

Hazardous Area Requirements for Class I Areas – Electrical Installation

For more knowledge please check Ebooksterminal.com