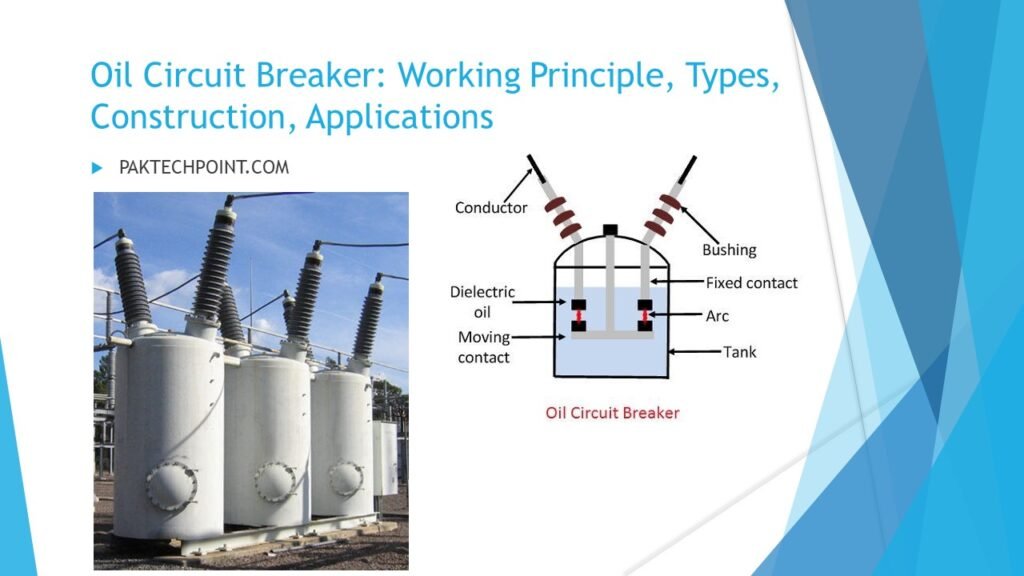

Oil circuit breakers (OCBs) are a type of circuit breaker widely used for their efficient arc extinguishing capabilities. They rely on the use of oil as an arc quenching medium, making them suitable for high-power applications and offering reliable protection against electrical faults.

In this comprehensive guide, we will explain into the working principle, types, construction, and applications of oil circuit breakers, including Bulk Oil Circuit Breaker (BOCB), Minimum Oil Circuit Breaker (MOCB), Plain Break Oil Circuit Breaker, and Arc Control Oil Circuit Breaker.

Additionally, we will explore the advantages and disadvantages of using oil circuit breakers in various electrical systems.

What is Oil Circuit Breaker?

An oil circuit breaker (OCB) is a type of electrical circuit breaker that uses insulating oil as an arc extinguishing medium to interrupt the flow of current during fault conditions in an electrical circuit. It is designed to protect electrical systems from overloads, short-circuits, and other electrical faults by quickly extinguishing the electrical arcs that occur during these events.

Working Principle of Oil Circuit Breaker:

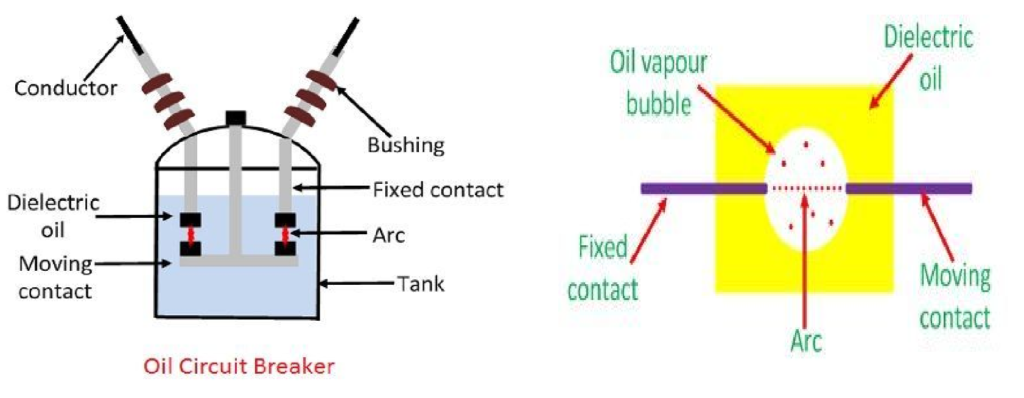

The working principle of an oil circuit breaker is based on the cooling and quenching effect of oil on electrical arcs. When a fault occurs in the electrical circuit, such as an overload or short-circuit, the current flowing through the breaker generates an arc. The arc is then directed into a chamber filled with insulating oil. The oil rapidly cools and de-ionizes the arc, extinguishing it and interrupting the flow of current in the circuit.

Types of Oil Circuit Breakers:

1. Bulk Oil Circuit Breaker (BOCB):

BOCB is the earliest and most common type of oil circuit breaker. It consists of a large quantity of oil contained in a tank. The arc generated during fault conditions is directed into the oil-filled tank, where it is extinguished. However, BOCBs are relatively bulky and require regular maintenance.

A. Plain Break Oil Circuit Breaker:

This type of oil circuit breaker employs a simple construction with an arc chute and oil-filled chamber. It is suitable for low-voltage applications and offers basic protection against electrical faults.

B. Arc Control Oil Circuit Breaker:

Arc control oil circuit breakers are designed to control the movement and direction of the arc during fault conditions. They use magnetic fields or mechanical devices to guide the arc, leading to better arc interruption and increased breaking capacity.

Arc control oil circuit breakers are a specific type of oil circuit breaker designed to control and extinguish electrical arcs efficiently during fault conditions. These breakers utilize the cooling and arc-quenching properties of insulating oil, combined with a controlled flow of gas, to interrupt the current and protect electrical systems. Within the category of arc control oil circuit breakers, there are two main types:

a. Self-Blast Oil Circuit Breaker:

The self-blast oil circuit breaker is a type of arc control breaker that relies on the pressure generated by the expanding gases produced during arc extinction to extinguish the arc. When a fault occurs, the arc is directed into a chamber filled with insulating oil. As the arc vaporizes the oil, it generates high-pressure gases, which create a blast effect. This blast pressure rapidly cools and quenches the arc, leading to its extinction. The self-blast mechanism is self-generating and does not require any additional energy source to clear the fault.

Arc control oil circuit breakers are an essential part of modern electrical protection systems, ensuring the stability and reliability of electrical networks by promptly and effectively handling fault conditions. Their ability to control and extinguish arcs efficiently makes them a vital component in safeguarding electrical equipment and preventing damage during electrical faults.

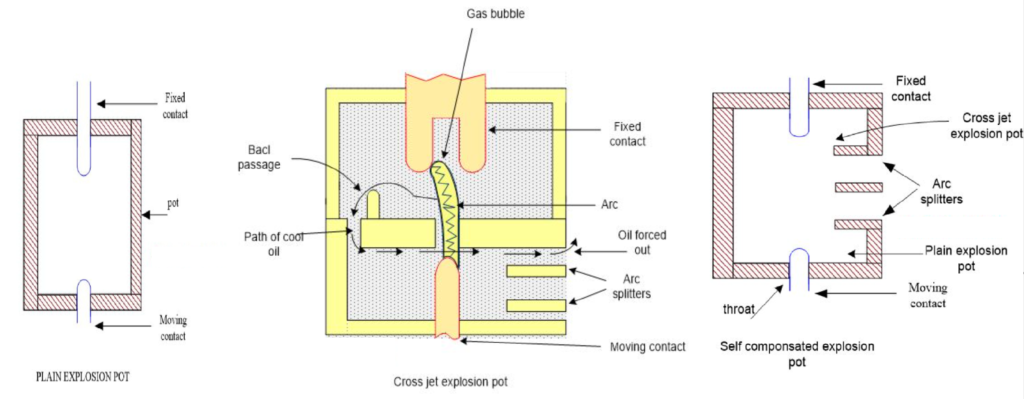

In self-blast oil circuit breakers, the explosion pot is a critical component responsible for directing the high-pressure gases generated during arc extinction to achieve effective interruption of the electrical fault. The design of the explosion pot plays a significant role in the breaker’s performance, and various designs offer specific benefits. Here are the three common designs of the explosion pot:

- Plain Explosion Pot:

The plain explosion pot is the simplest design, comprising a cylindrical chamber filled with insulating oil. When a fault occurs, the arc is directed into the explosion pot, vaporizing the oil inside. As the oil vaporizes, it creates high-pressure gases, leading to a self-generated blast effect. The generated pressure is utilized to cool and extinguish the arc, effectively interrupting the fault. The plain explosion pot design is reliable and requires minimal maintenance, making it suitable for various applications. - Cross Jet Explosion Pot:

The cross jet explosion pot is an enhanced design that includes additional gas nozzles or jets strategically positioned inside the explosion pot. When the arc is directed into the pot, these jets release compressed air or nitrogen in a cross-flow pattern across the arc’s axis. This cross-jet arrangement enhances the cooling and quenching effect on the arc, ensuring faster and more efficient arc interruption. The cross jet explosion pot design is commonly used in high-voltage and high-current applications where swift fault clearance is essential. - Self-Compensated Explosion Pot:

The self-compensated explosion pot is a sophisticated design that incorporates a feedback mechanism to regulate the blast pressure. It includes a movable piston or diaphragm that responds to the pressure changes within the pot. As the pressure increases during fault interruption, the piston or diaphragm moves to adjust the volume inside the pot, thus maintaining a constant pressure. This self-compensating feature ensures that the blast pressure remains consistent, optimizing the arc interruption process. The self-compensated explosion pot is often used in critical applications where precise control over arc extinction is required.

The selection of the explosion pot design depends on the specific requirements of the electrical system, the magnitude of fault currents, and the desired performance characteristics. Each design offers its advantages in terms of reliability, efficiency, and control over arc interruption. Regardless of the design, self-blast oil circuit breakers equipped with these explosion pots play a vital role in ensuring the safe and reliable operation of electrical networks by promptly and effectively handling fault conditions.

b. Forced Blast Oil Circuit Breaker:

In contrast, the forced blast oil circuit breaker utilizes an external source of gas, such as compressed air or nitrogen, to create a controlled blast effect for arc extinction. The breaker is equipped with a high-pressure gas reservoir or compressor that can release the gas into the arc chamber when a fault is detected. The forced flow of gas around the arc aids in cooling and quenching the arc, leading to its interruption. This type of breaker provides more precise control over the arc extinction process and can be adjusted based on the specific application requirements.

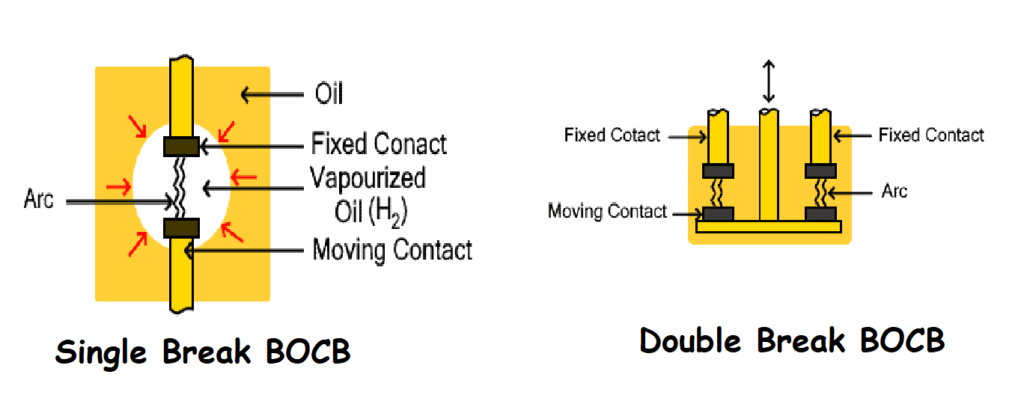

In Forced Blast Oil Circuit Breaker, the method of breaking the current-carrying contacts determines the type of breaker. Among the various types of OCBs, the Bulk Oil Circuit Breaker (BOCB) is an important category, and it can be further classified into two main types:

1. Single Break Bulk Oil Circuit Breaker:

In a Single Break Bulk Oil Circuit Breaker, there is only one point of interruption for the current-carrying contacts. When a fault occurs, the arc generated between the contacts is directed into the oil-filled chamber. The arc vaporizes the oil, creating high-pressure gases that lead to a self-generated blast effect. This high-pressure blast helps in cooling and extinguishing the arc, effectively interrupting the fault. The Single Break BOCB is a reliable and commonly used circuit breaker in medium and high-voltage applications.

Double Break Bulk Oil Circuit Breaker:

In contrast, the Double Break Bulk Oil Circuit Breaker has two points of interruption for the current-carrying contacts. When a fault occurs, the arc is first directed into the first oil-filled chamber, where it is partially extinguished. The arc then proceeds to the second oil-filled chamber, where it is further interrupted. This double break arrangement provides enhanced arc interruption capabilities, as it divides the arc into two stages, increasing the overall cooling and quenching effect. The Double Break BOCB is often employed in high-voltage and high-current applications, where superior performance in fault clearing is required.

Both types of Bulk Oil Circuit Breakers offer efficient and reliable arc interruption, making them suitable for a wide range of power system applications. The choice between a Single Break BOCB and a Double Break BOCB depends on the specific requirements of the electrical system, including the voltage level, fault currents, and the need for more advanced fault-clearing capabilities. Regardless of the type, BOCBs play a crucial role in protecting electrical networks from faults and ensuring safe and reliable power distribution.

Both self-blast and forced blast oil circuit breakers offer reliable arc control and interruption capabilities, making them suitable for high-voltage applications. These breakers are commonly used in power transmission and distribution systems, substations, and industrial installations where high fault currents need to be safely interrupted.

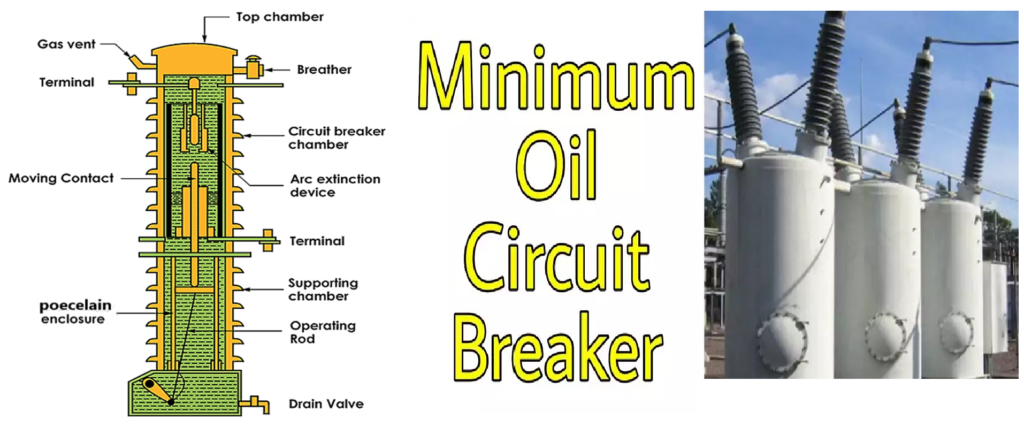

2. Minimum Oil Circuit Breaker (MOCB):

MOCBs use a smaller amount of oil compared to BOCBs. The arc is directed into an arc chute filled with oil, which helps in faster arc extinction and reduces the overall size of the circuit breaker. MOCBs are widely used due to their compact design and improved efficiency.

Minimum Oil Circuit Breakers (MOCBs) are a type of oil circuit breaker that uses a minimum quantity of oil for arc extinction during fault conditions. Unlike Bulk Oil Circuit Breakers (BOCBs), MOCBs do not use oil for insulation purposes, which reduces the fire hazard and makes them more compact and efficient. MOCBs are commonly used in medium and high-voltage applications to provide reliable and effective protection against electrical faults.

MOCBs consist of two main chambers: the arc chamber and the insulating chamber. The arc chamber contains the fixed and moving contacts filled with oil, which is utilized for extinguishing the arc during the interruption process. The insulating chamber provides support to the arc chamber and is filled with oil for insulation purposes.

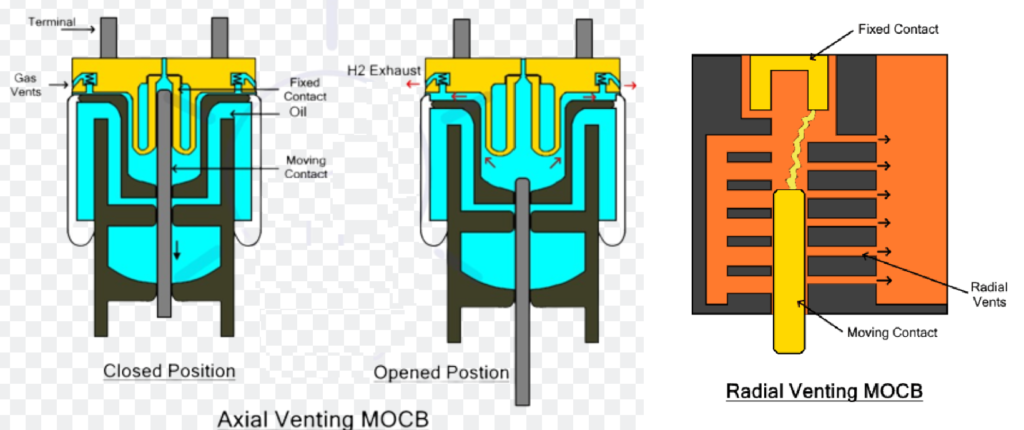

There are two types of Minimum Oil Circuit Breakers based on the design of the gas venting system:

A. Axial Venting Minimum Oil Circuit Breaker:

In Axial Venting MOCBs, the gas vents are arranged in an axial direction, meaning they are aligned along the axis of the circuit breaker. When the moving contact separates from the fixed contact, an arc is formed. The generated gases and vaporized oil are released through the axial vents. The axial direction of the vents allows the gases to flow out in a straight line, leading to effective arc cooling and arc extinction. Axial Venting MOCBs are known for their simplicity and reliable performance.

B. Radial Venting Minimum Oil Circuit Breaker:

In Radial Venting MOCBs, the gas vents are arranged in a radial pattern, encircling the arc chamber. When the moving contact opens, the gases and vaporized oil are expelled radially outward from the arc chamber. The radial venting design ensures uniform distribution of gases around the arc, leading to better cooling and quicker arc extinction. Radial Venting MOCBs are preferred in applications where faster arc quenching is required, and they are suitable for higher fault currents.

Both types of Minimum Oil Circuit Breakers offer efficient and reliable arc interruption using minimum oil. They provide essential protection for electrical systems, safeguarding equipment and personnel from potential hazards during fault conditions. The choice between Axial Venting MOCB and Radial Venting MOCB depends on specific application requirements, fault levels, and the desired performance of the circuit breaker in the electrical system.

Oil Impulse Circuit Breaker

The Oil Impulse Circuit Breaker is a type of Minimum Oil Circuit Breaker (MOCB) that utilizes external means to develop pressure for arc quenching. It is designed to use a minimal amount of oil, making it a compact and efficient solution for interrupting electrical faults. The operation of the Oil Impulse Circuit Breaker involves the use of a piston that compresses the oil, which is then released through a jet fixed between the contacts to extinguish the arc. This design allows for effective arc interruption while minimizing the amount of oil required.

Advantages of Oil Impulse Circuit Breaker:

- Minimal Oil Usage: The Oil Impulse Circuit Breaker requires only a small quantity of oil for its operation. This reduces the overall weight and size of the circuit breaker, making it a space-saving solution.

- Reduced Fire Hazard: The use of lesser oil in the circuit breaker significantly reduces the risk of fire hazards during operation or in the event of a fault.

- Lightweight and Compact: Due to its efficient design and minimal oil usage, the Oil Impulse Circuit Breaker is lightweight and compact, making it easier to install and handle.

- Cost-Effective: Compared to Bulk Oil Circuit Breakers (BOCBs), the Oil Impulse Circuit Breaker is relatively more cost-effective, making it a practical choice for various applications.

- Easy Maintenance: The circuit breaker’s design allows for straightforward maintenance, and the oil can be easily replaced when needed.

- Suitable for Infrequent Use: The Oil Impulse Circuit Breaker is ideal for installations where it is not frequently used, as it can efficiently interrupt faults when required.

Disadvantages of Oil Impulse Circuit Breaker:

- Carbonization Effects: The reduced amount of oil in the circuit breaker makes it more susceptible to carbonization effects from the contacts. Carbonization can lead to reduced performance and efficiency.

- Dielectric Strength: The oil used in the Oil Impulse Circuit Breaker may quickly lose its dielectric strength over time, potentially affecting the breaker’s insulation capabilities.

- Frequent Maintenance: Due to the impact of carbonization and potential oil degradation, the Oil Impulse Circuit Breaker may require more frequent maintenance to ensure reliable operation.

In conclusion, the Oil Impulse Circuit Breaker offers several advantages, such as minimal oil usage, reduced fire hazards, and cost-effectiveness. However, it is important to consider the effects of carbonization and the need for regular maintenance to ensure the circuit breaker’s continued efficiency and reliability. Overall, the Oil Impulse Circuit Breaker is a suitable choice for applications that demand efficient arc interruption with minimal oil requirements.

Construction of Oil Circuit Breakers:

Oil circuit breakers are typically composed of the following components:

- Main tank filled with insulating oil

- Arc chute to direct and cool the arc

- Contacts for circuit interruption

- Operating mechanism for manual or automatic operation

- Trip unit for fault detection and tripping

- Control panel for monitoring and protection settings

Oil Circuit Breaker Applications:

Oil circuit breakers are primarily used in high-voltage applications, such as power transmission and distribution systems, substations, and industrial installations. They are effective in interrupting heavy fault currents and ensuring the safe operation of electrical networks. OCBs find applications in power generation plants, railways, oil and gas facilities, and large industrial complexes.

Advantages of Oil Circuit Breakers:

- High breaking capacity suitable for high-power applications.

- Efficient arc extinction and reliable fault protection.

- Suitable for high-voltage systems and large current ratings.

- Can be used for both AC and DC circuits.

- Long service life with proper maintenance.

Disadvantages of Oil Circuit Breakers:

- Bulkier and heavier compared to other circuit breaker types.

- Require regular maintenance and periodic oil filtration.

- Possibility of oil leakage and environmental concerns.

- Not suitable for compact and space-constrained installations.

Conclusion:

Oil circuit breakers are an integral part of modern electrical systems, providing efficient protection against electrical faults and ensuring the safe and reliable operation of power networks. With various types available, such as BOCB, MOCB, Plain Break, and Arc Control OCBs, they can be tailored to suit different voltage levels and applications.

Despite their advantages, careful consideration of maintenance requirements and environmental concerns is necessary while deploying oil circuit breakers in electrical installations. By understanding the working principle, types, construction, applications, and pros and cons of oil circuit breakers, electrical engineers can make informed decisions to implement them effectively in their systems.