In the world of electrical power distribution, safety and reliability are of paramount importance. One indispensable device that plays a crucial role in safeguarding electrical circuits and equipment from overcurrents and short circuits is the Air Circuit Breaker (ACB). As a fundamental component in power distribution networks, the ACB ensures efficient switching and quick fault clearance, making it an essential guardian of electrical systems.

In this comprehensive article, we will delve into the world of Air Circuit Breakers, exploring their working principle, construction, different types, testing procedures, advantages, disadvantages, and wide-ranging applications. Understanding the inner workings of ACBs will shed light on the science behind their efficient arc interruption, their design features, and how they have evolved to meet the ever-increasing demands of modern power distribution systems. So, let’s embark on a journey to uncover the mysteries and marvels of the Air Circuit Breaker.

What is Air Circuit Breaker?

Air Circuit Breakers (ACBs) play a crucial role in electrical power distribution systems, protecting circuits and electrical equipment from overcurrents and short circuits. As an essential component of power distribution networks, ACBs offer reliable protection and efficient switching capabilities. In this comprehensive guide, we will delve into the world of Air Circuit Breakers, exploring their working principle, construction, various types, testing procedures, advantages, disadvantages, and applications.

Working Principle of Air Circuit Breaker

The working principle of an Air Circuit Breaker is based on the release of high-pressure compressed air to extinguish the arc formed during the circuit interruption. When a fault occurs, the ACB’s operating mechanism rapidly releases the contacts to create a gap, allowing the arc to form between them. The pressure of the compressed air interrupts the arc by blowing it away from the contacts, extinguishing it quickly and safely.

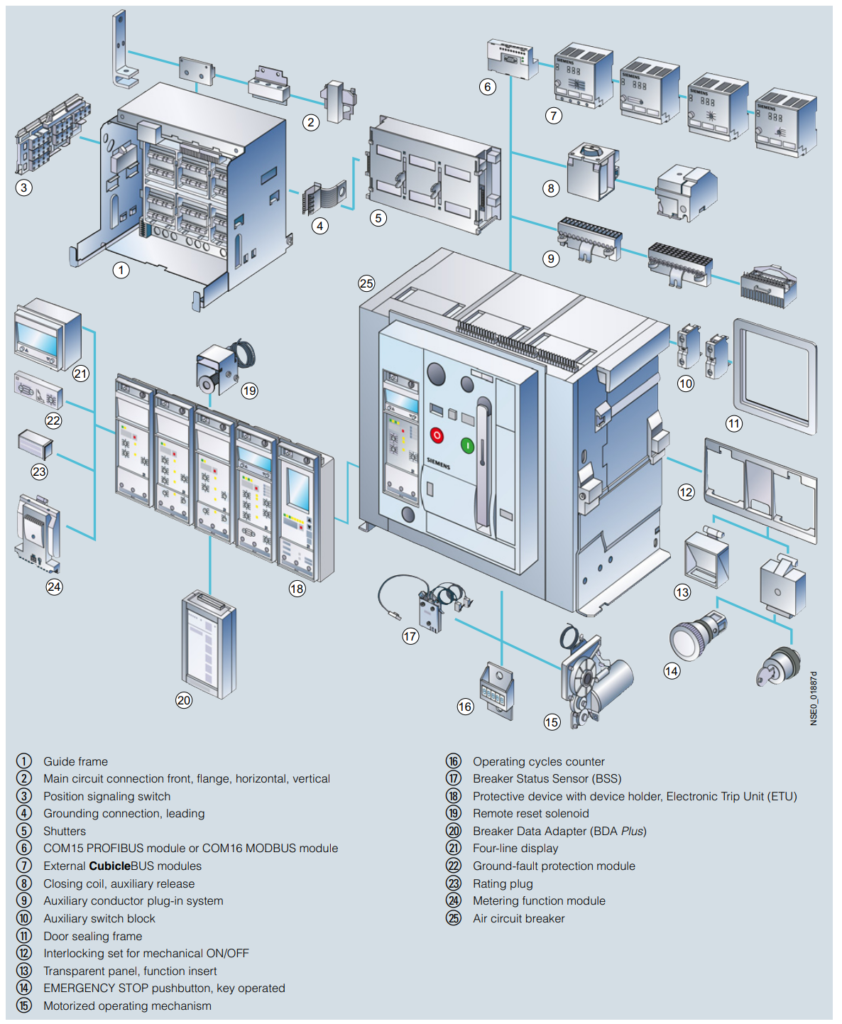

Air Circuit Breaker Construction

An Air Circuit Breaker consists of several essential components that work together to ensure efficient operation and reliable protection. The key components include:

a. Operating Mechanism: The operating mechanism is responsible for opening and closing the contacts and initiating the trip mechanism during a fault condition.

b. Arc Chutes: The arc chutes are designed to redirect and split the arc into smaller arcs, which helps in the interruption process and reduces wear and tear on the contacts.

c. Contacts: The main contacts provide the electrical connection between the circuit and the breaker. When a fault occurs, these contacts separate to create a gap for the arc to form.

d. Trip Mechanism: The trip mechanism senses the fault current and initiates the opening of the contacts, ensuring swift circuit interruption.

Types of Air Circuit Breakers

a. Plain Break Type ACB or Cross-Blast ACB: This type of ACB uses a cross-blast technique to clear the arc and extinguish it effectively. The arc chutes are positioned in such a way that the blast from one chute crosses the arc drawn in the next chute, facilitating rapid arc interruption.

b. Magnetic Blowout Type ACB: This ACB utilizes a magnetic field to blow out the arc from the contacts, ensuring quick and reliable arc interruption.

c. Air Chute Air Break Circuit Breaker: In this type, multiple air chutes are used to redirect and cool the arc, improving the arc interruption process.

d. Air Blast Circuit Breaker: These ACBs employ a high-pressure air blast to blow out and quench the arc, ensuring efficient interruption.

Functions of Air Circuit Breakers:

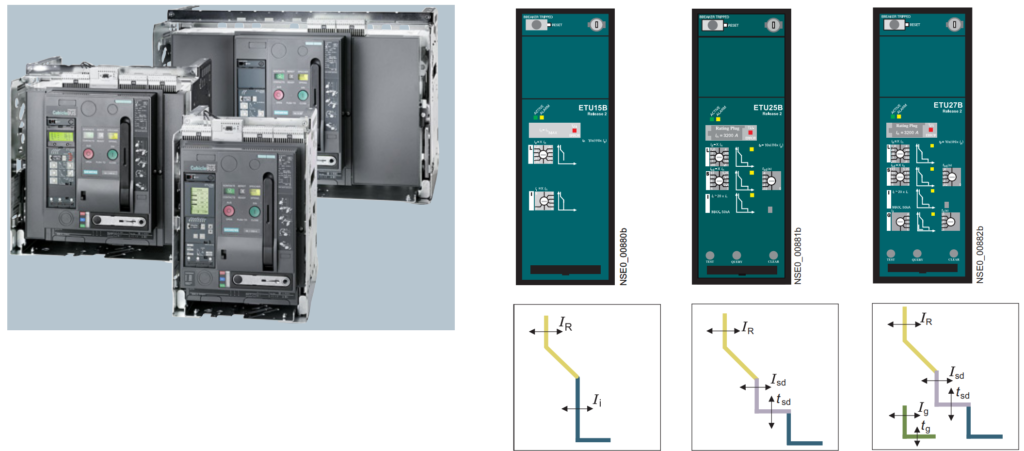

Electronic Trip Units (ETUs) are vital components in modern circuit breakers that provide advanced protection functions and enhance the overall reliability and safety of electrical systems. These sophisticated devices offer a wide array of protection features to safeguard electrical circuits and equipment from various faults, overloads, and short circuits. In this section, we will explore the various functions and capabilities of Electronic Trip Units, which serve as a significant advancement over traditional electromechanical trip units.

Basic Protection Functions:

- Overload Protection (L): The ETUs offer precise overload protection, monitoring the current flow in the circuit. When the current exceeds the set limit, the ETU promptly trips the circuit breaker to prevent damage due to sustained high currents.

- Short-Time Delayed Short-Circuit Protection (S): In case of a short circuit, the ETU responds with short-time delay to allow for coordination with downstream protective devices before tripping the breaker.

- Instantaneous Short-Circuit Protection (I): For immediate and decisive action, the ETU provides instantaneous short-circuit protection, detecting and rapidly clearing any short-circuit faults.

- Neutral Conductor Protection (N): The ETU can also safeguard the neutral conductor from overcurrents, ensuring the balance and integrity of three-phase systems.

- Ground-Fault Protection (G): To detect ground faults and protect against earth leakage currents, the ETU offers effective ground-fault protection.

Additional Functions:

- Adjustable Neutral Conductor Protection: The ETU allows the option to adjust the protection settings for the neutral conductor as per specific requirements.

- Load Monitoring: ETUs can continuously monitor the load currents, providing valuable insights into the performance and health of the electrical system.

- Short-Time Delay Short-Circuit Protection Switchable to Instantaneous (I²t): The ETU offers the flexibility to switch between short-time delay short-circuit protection and instantaneous protection based on the application’s needs.

- Overload Protection Switchable to I⁴t: Similar to the previous function, the ETU can be switched to I⁴t mode to enhance coordination and protection during overload conditions.

Parameterization and Display:

- Parameterization through Rotary Coding Switches: The ETUs can be easily configured using rotary coding switches, allowing quick adjustments to protection settings with ten distinct steps.

- Parameterization through Communication: Some advanced ETUs support parameterization through communication protocols such as PROFIBUS DP, MODBUS, or Ethernet, enabling precise and remote configuration.

- LCD Display: ETUs are equipped with LCD displays, either alphanumerical or graphical, to provide real-time information about protection status and system conditions.

Metering Function:

- Metering Function Plus: Advanced ETUs offer comprehensive metering capabilities, allowing detailed monitoring of various electrical parameters such as voltage, current, power, and energy consumption.

Communication:

- CubicleBUS: ETUs equipped with CubicleBUS enable seamless communication with other devices within the switchgear cubicle.

- Communication through PROFIBUS DP: For enhanced connectivity and integration into automation systems, some ETUs support communication through the PROFIBUS DP protocol.

- Communication through MODBUS: ETUs with MODBUS communication capability facilitate easy integration with industrial control systems.

- Communication via Ethernet: High-end ETUs can establish communication via Ethernet, enabling remote access and advanced monitoring and control.

Air Circuit Breaker Testing Procedure

To ensure the proper functioning and reliability of Air Circuit Breakers, regular testing and maintenance are essential. Some of the key testing procedures include:

a. Insulation Resistance Test: This test measures the insulation resistance between the live parts and the ground to detect any insulation deterioration.

b. Contact Resistance Test: The contact resistance test checks the resistance of the contacts to ensure they are functioning correctly.

c. Trip Coil Test: This test verifies the functionality of the trip coil, which is responsible for opening the contacts during a fault.

d. Closing Coil Test: The closing coil test examines the closing coil’s performance, ensuring smooth and efficient closing of the contacts.

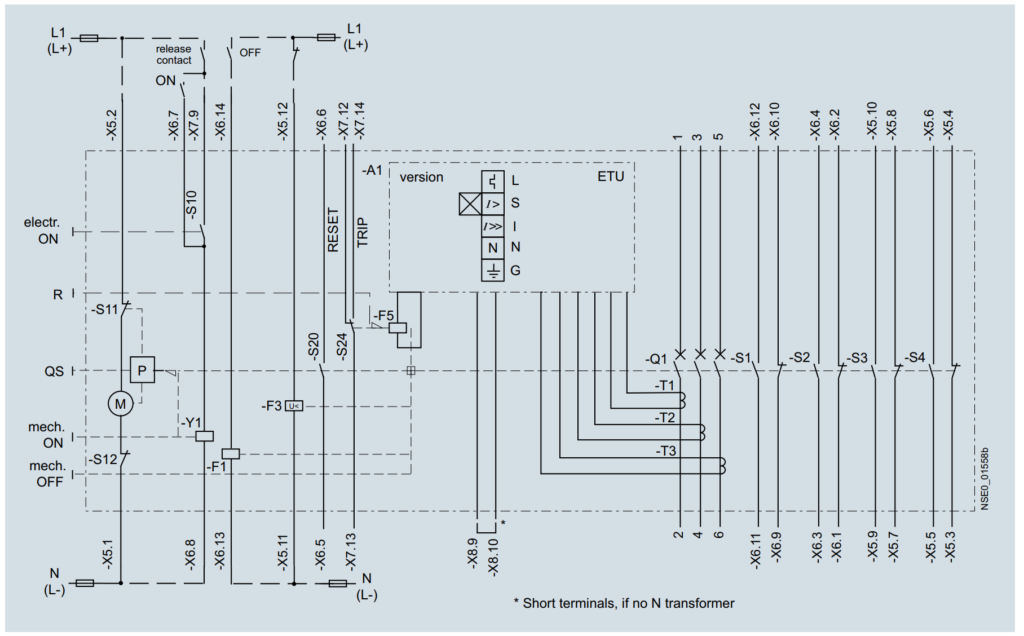

Example of an overall circuit diagram for 3WL circuit breakers

Function diagram of 3WL air circuit breaker

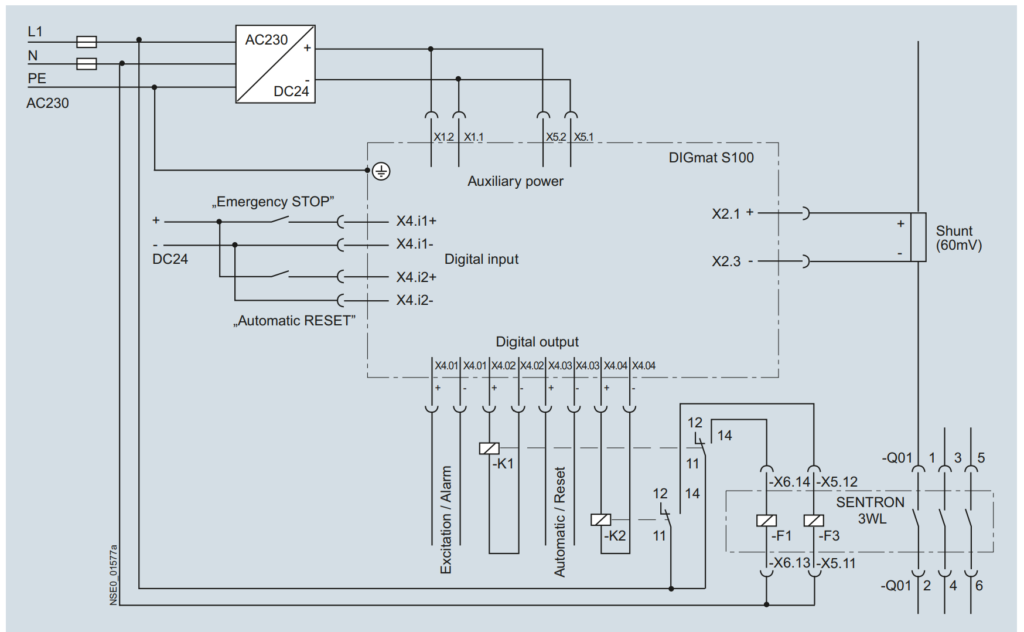

General Circuit diagrams of Air Circuit Breakers

Advantages of Air Circuit Breakers

- High breaking capacity, suitable for high-power applications.

- Rapid arc interruption and quick restoration of power supply.

- Simple construction, making it easy to install and maintain.

- Effective protection against overcurrents and short circuits.

Disadvantages of Air Circuit Breakers

- Relatively larger in size compared to some other circuit breaker types.

- Limited suitability for DC applications.

- Arc interruption may produce noise and vibration.

Applications of Air Circuit Breakers

- Power distribution systems in residential, commercial, and industrial buildings.

- Protection of electrical motors, generators, transformers, and other critical electrical equipment.

- Used in industrial plants, data centers, and large manufacturing facilities.

Conclusion

Air Circuit Breakers serve as vital components in electrical power distribution systems, providing reliable protection and efficient switching capabilities. Their working principle, construction, types, testing procedures, advantages, disadvantages, and applications make them an indispensable asset in maintaining electrical safety and reliability. As technology continues to advance, the role of Air Circuit Breakers in power distribution will only become more critical in ensuring uninterrupted and efficient electricity supply.

Finally we are going to attach one Air Circuit Breaker Manual of Siemens to Study technical specs of breaker.