Estimated reading time: 3 minutes

This article is about HVAC Valves types and and application used in HVAC System.

Table of contents

14. Types of Valves used in HVAC systems

14.6 Submittals

14.6.1 Product data for each type of valve indicated including body, seating, and trim materials; valve design; pressure and temperature classifications, end connections, arrangement, dimensions and required clearances.

14.7 Quality Assurance

14.7.1 Ferrous valves shall comply with ASME B16.10 and ASME B16.34 for dimension and design criteria.

14.8 Valves – General

14.8.1 Valves of same manufacture shall be provided throughout where possible.

14.8.2 Valves shall have manufacturer’s name and pressure rating clearly marked on outside of body.

14.8.3 Valve pressure and temperature ratings shall not be less than indicated and as required for system pressures and temperatures.

14.8.4 Extended valve stems shall be provided on insulated valves.

14.8.5 Valve flanges shall comply with ASME B16.1 for cast-iron valves and ASME B16.5 for steel valves.

14.8.6 Threaded end valve threads complying with ASME B1.20.1.

14.9 Valve Connections

14.9.1 Valves 2 inch and smaller – threaded body.

14.9.2 Valves 2-1/2 inch and larger – flanged body, except for butterfly and wafer check valves.

14.10 Gate Valves

Gate valves are used across a wide range of applications. They come in multiple sizes and configurations for use in general service on water, oil, or compressed gas. Specialized models are recommended for fire main shutoff and distribution service.

14.10.1 ½” – 2” – Class 125, bronze screwed complying with MSS SP-80, Type 2.

14.10.2 2½” and over – Class 150, cast iron, outside screw and yoke, solid wedge disc, raised face flange complying with MSS SP-70, Type I.

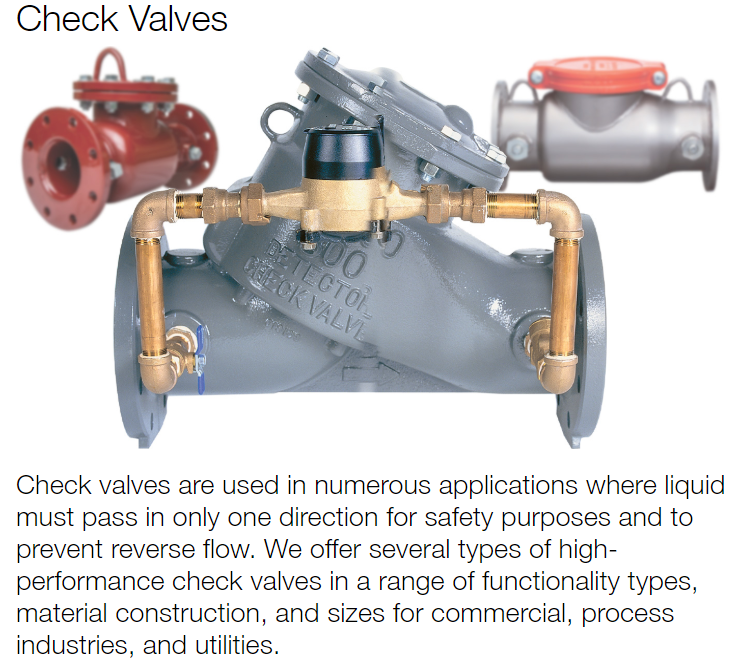

14.11 Check Valves

14.11.1 ½” – 2” – Class 150, bronze screwed complying with MSS SP-80, Type 4.

14.11.2 2½“ and over – Class 125, gray iron complying with MSS SP-71, Type II.

14.12 Plug Valves

14.12.1 ½” – 2” – Class 125, cast iron complying with MSS SP-78.

14.12.2 2½”and over – Class 125, cast iron complying with MSS SP-78.

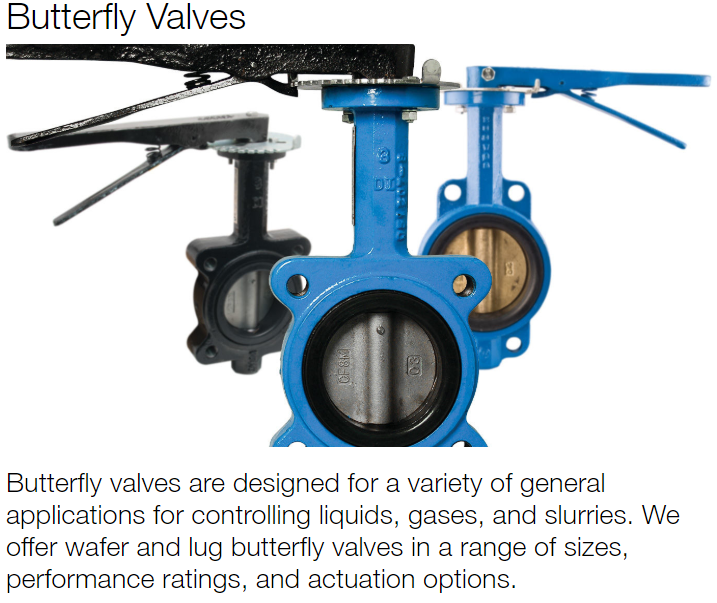

14.13 Butterfly Valves

14.13.1 1/2 inch and over – 150 psig cold working pressure rating, ferrous alloy, with ethylene- propylene-dieneterpolymer rubber liner complying with MSS SP-67, Type I.

14.14 Drain Valves

14.14.1 ¾”- complying with MSS SP-45.

14.15 Ball Valves

14.15.1 ½” – 2” – 400 psig, bronze body, teflon seats, two piece, 600 psig minimum CWP rating complying with MSS SP-110.

14.15.2 2½”and over – Class 150, ferris alloy body complying with MSS SP-72 with flanged ends.

14.16 Valves Installation

14.16.1 Valves shall be installed to allow full stem movement with stems upright or horizontal, not inverted.

14.16.2 Gate valves shall be installed for shut-off and isolating service, to isolate equipment, parts of systems or vertical risers.

14.16.3 Drain valves shall be provided at low points of piping system.