This article provides criteria for selecting ac motors. This article is mainly based on lEC Standards and ANSI/IEEE based. Main keywords for this article are AC Motors Selection Guide IEC, Hazardous Locations Motors, Squirrel-Cage Induction Motors, Motors Enclosure Types and Cooling Methods, AC Motors References.

AC Motors References

International Electrotechnical Commission (IEC)

IEC 60034 (series) Rotating electrical machines

IEC 60072-1 Dimension and output series for rotating electrical machines, Part 1: Frame numbers 56 to 400 and flange numbers 55 to 1080

IEC 60079 (series) Electrical apparatus for explosive gas atmospheres

IEC 60529 Degrees of protection provided by enclosures

IEC 61241 (series) Electrical apparatus fur use in the presence of combustible dust

AC Motors Selection Guide IEC Based in Process Industry

Motor enclosures can be classified as either open, totally enclosed or weather protected enclosures (for weather-protection see IEC 60034-5). Totally enclosed enclosures commonly used are totally enclosed non-ventilated (TENV) enclosures, used for some small fractional kilowatt motors; totally enclosed fan-cooled (TEFC) enclosures, used for most IEC frame motors and some large motors; and explosion-proof enclosures, used for all motors in Group IIA, IIB and IIC, Zone 0 and Zone 1 locations.

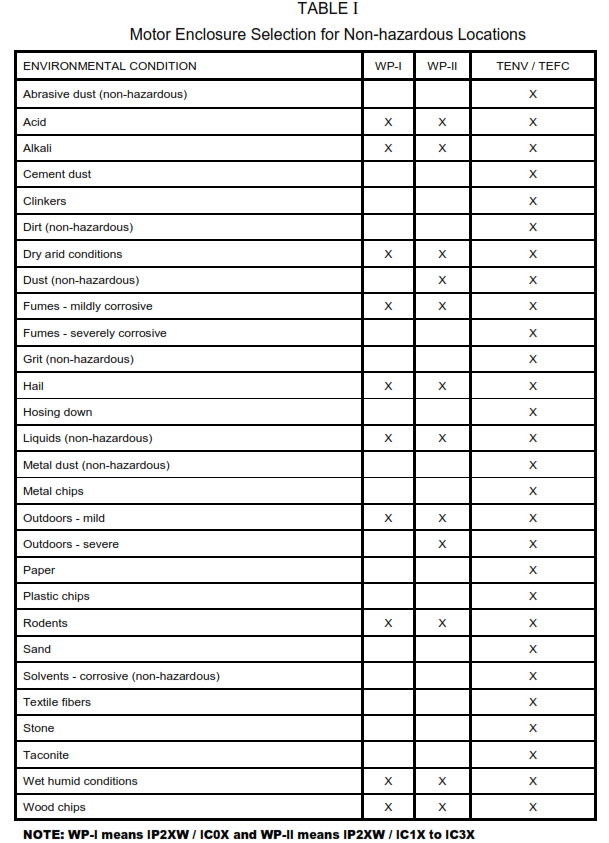

Following Tables I and II show types of motor enclosures recommended in various environmental conditions.

Environmental Conditions

Non-hazardous Locations Motors

- Environments that are considered by IEC to be non-hazardous may have conditions that damage motors and other electrical equipment. Non-hazardous locations may be classified as general-purpose (clean or dirty), dusty (nonhazardous), damp and wet, and corrosive.

- Moisture can enter a motor as a result of area activity or as rain, or it can enter as condensation when the motor is shut down. Even with a totally enclosed motor, the combination of humid conditions and rapid temperature changes can cause a breathing action that results in condensation of moisture inside the motor enclosure. Oil can enter a motor from bearing leakage. Moisture, dirt, oil, and corrosive chemicals can be drawn into a motor with ventilating air from the surrounding atmosphere.

- Contamination can cause both electrical and mechanical failures. Moisture, if allowed to accumulate, can lower insulation resistance and corrode interior surfaces. Ordinary dirt can absorb moisture and keep it in contact with winding insulation. Oil softens and damages protective finishes and enables dirt to cling to surfaces. Abrasive dirt, for example pigments, cement, coal, and coke can

wear through winding insulation. Conducting dirt collects on winding insulation surfaces and works into minute cracks, reducing insulation resistance.

Chemical deposits can attack winding varnish films and motor structural parts. Chemicals penetrate winding insulation and, in the presence of moisture, form a conducting electrolyte, which can cause winding failure. Dirt and foreign objects can become entangled in rotating parts or block ventilating passages and cause overheating. Moisture, dirt, and chemicals can contaminate bearing lubricant.

Hazardous Locations Motors (Classified)

Electrical installations are potential ignition sources.

- The definition of hazardous locations shall be in accordance with:

– IEC 60079-0 Electrical apparatus for explosive gas atmospheres, Part 0: General requirements

– IEC 60079-10 Electrical apparatus for explosive gas atmospheres, Part 10: Classification of hazardous areas

– IEC 61241-10 Electrical apparatus for use in the presence of combustible dust, Part 10: Classification of areas where combustible dusts are or may be present - The two main groups of the IEC Zone system are defined in IEC 60079-0, Paragraph 4.1

- Flammable and combustible gases, vapors and liquids Group II is subdivided as follows:

(a) Group IIA (materials, for example gasoline, hexane, naphtha, benzene, butane, propane, alcohol, lacquer solvent and natural gas)

(b) Group IIB (materials, for example ethyl ether vapor, ethylene and cyclopropane)

(c) Group IIC (acetylene, hydrogen and manufacturer gas)

In accordance with IEC 60079-10, Paragraph 2.5 hazardous areas are classified into zones based upon the frequency of the occurrence and duration of an explosive gas atmosphere as follows:

(a) Zone 0:

Place in which an explosive atmosphere consisting of a mixture with air or flammable substances in the form of gas, vapor or mist is present continuously or for long periods or frequently

(b) Zone 1:

Place in which an explosive atmosphere consisting of a mixture with air or flammable substances in the form of gas, vapor or mist is likely to occur in normal operation occasionally

(c) Zone 2:

Place in which an explosive atmosphere consisting of a mixture with air or flammable substances in the form of gas, vapor or mist is not likely to occur in normal operation but, if it does occur, will persist for a short period only - Combustible dust

In accordance with IEC 61241-10, Paragraph 3.6 means combustible dust also fibers or flyings. In general IEC 61241-10 adopts the concept, similar to that used for flammable gases and vapor, of using area classification to give an assessment of the risk of fire and/or explosion from dust clouds.

In accordance with IEC 61241-10, Paragraph 6 areas classified for explosive dust atmospheres are divided into zones, which are identified according to the frequency and duration of the occurrence of explosive dust/air atmospheres as follows:

(a) Zone 20:

Place in which an explosive atmosphere, in the form of cloud of combustible dust in air, is present continuously, or for long periods or frequently for short periods

(b) Zone 21:

Place in which an explosive atmosphere, in the form of a cloud of combustible dust in air, is likely to occur occasionally in normal operation

(c) Zone 22:

Place in which an explosive atmosphere, in the form of a cloud of combustible dust in air, is not likely to occur in normal operation but, if ti does occur, will persist for a short period only

Motors Enclosure Types and Cooling Methods

The definitions given in this Paragraph shall be in accordance with:

IEC 60034-5 Rotating electrical machines, Part 5: Degrees of protection provided by the integral design of rotating electrical machines (IP code) – Classification

IEC 60034-6 Rotating electrical machines, Part 6: Methods of cooling (IC code)

IEC 60079-0 Electrical apparatus for explosive gas atmospheres, Part 0: General requirements

IEC 60079-1 Electrical apparatus for explosive gas atmospheres, Part 1: Flameproof enclosures “d”

IEC 60079-7 Electrical apparatus for explosive gas atmospheres, Part 7: Increased safety “e”

IEC 60079-15 Electrical apparatus for explosive gas atmospheres, Part 15: Construction, test and marking of type of protection “n” electrical apparatus

IEC 61241 (series) Electrical apparatus for use in the presence of combustible dust

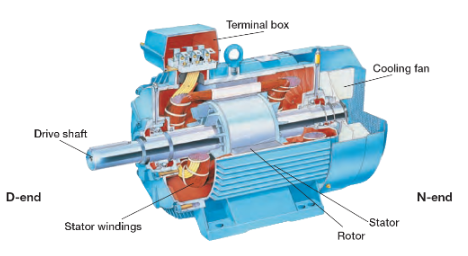

Open Machine

See IEC 60034. An open machine (IP00, IP01) has ventilating openings that permit passage of external cooling air over and around the windings of the machine. When this term is used for large apparatus without qualification, it designates a machine having no restriction to ventilation other than that necessitated by mechanical construction. A „machine‟ can be either a motor or a generator. An open motor does not perform well in described environmental conditions.

- Drip-proof (ODP): is an open machine in which the ventilating openings are so constructed that successful operation is not affected when drops of liquid or solid particles strike or enter the enclosure at any angle from 0 to 15° downward from the vertical IP01, IP02, IP12).

- Splash-proof: A splash-proof machine (IP13, IP14) is an open machine in which the ventilating openings are so constructed that successful operation is not affected when drops of liquid or solid particles strike or enter the enclosure at any angle not greater than 100° downward from the vertical.

- Semi-guarded: A semi-guarded machine (IC01) is an open machine in which part of the ventilating openings in the machine, usually in the top half, are guarded as in a guarded machine, but the others are left open.

- Guarded: A guarded machine (IC01) is an open machine in which all openings giving direct access to live metal or rotating parts (except smooth rotating surfaces) are limited in size by the structural parts or by screens, baffles, grills, expanded metal, or other means to prevent accidental contact with hazardous parts.

- Drip-proof Guarded: A drip-proof guarded machine (IC01) is a drip-proof machine whose ventilating openings are guarded.

- Open Externally Ventilated: An open externally ventilated machine (IC06) is one that is ventilated by means of a separate machine-driven blower mounted on the machine enclosure. Mechanical protection is as defined. This machine is sometimes known as a blower-ventilated or a force-ventilated machine.

- Open Pipe-Ventilated: An open pipe-ventilated machine is an open machine except that openings for the admission of the ventilating air are so arranged that inlet ducts or pipes can be connected to them. Open pipe-ventilated machines can be self-ventilated (air circulated by means integral with the machine, for example IC11) or force-ventilated (air circulated by means external to and not a part of the machine, for example IC16).

Totally Enclosed Machine

IEC 60034 defines a totally enclosed machine as one so enclosed as to prevent the free exchange of air between the inside and the outside of the case but not sufficiently enclosed to be termed airtight.

- Totally Enclosed Non-ventilated (TENV): TENV machine (IC410) is a totally enclosed machine that is not equipped for cooling by means external to the enclosing parts. TENV enclosures are generally suitable only for small motors.

- Totally Enclosed Fan-Cooled (TEFC): TEFC machine (IC411) is a totally enclosed machine that is equipped for external cooling by means of a fan or fans integral with the machine but external to the enclosing parts.

- Explosion-Proof: Is a totally enclosed machine whose enclosure is designed and constructed to withstand an explosion of a specified gas or vapor which may occur within it and to prevent the ignition of the specified gas or vapor surrounding the machine by sparks, flashes, or explosions of the specified gas or vapor which may occur within the machine casing (IP55, for enclosure design see IEC 60079-0, IEC 60079-1, IEC 60079-7, IEC 60079-15).

- Dust-Ignition-Proof: A dust-ignition-proof machine is a totally enclosed machine whose enclosure is designed and constructed to exclude ignitable amounts of dust or amounts which might affect performance or rating, and which will not permit arcs, sparks, or heat otherwise generated or liberated inside the enclosure to cause ignition of exterior accumulations or atmospheric suspensions of a specific dust on or in the vicinity of the enclosure (Zone 21 IP65, Zone 22 IP55, for enclosure design see IEC 61241 series).

- Waterproof: A waterproof machine (IP55) is a totally enclosed machine so constructed that it will exclude water applied in the form of a stream from a hose, except that leakage may occur around the shaft provided it is prevented from entering the oil reservoir and provision is made for automatically draining the machine. The principal applications of waterproof motors are dairies, food cleaning and processing plants (particularly canneries), exposed docks and piers, and on-deck marine installations.

- Totally Enclosed Pipe-Ventilated: A totally enclosed pipe-ventilated machine (IP44) has openings arranged so that when inlet and outlet ducts or pipes are connected to them there is no free exchange of internal air and air outside the case. Totally enclosed pipe-ventilated machines can be self-ventilated (air circulated by means integral with the machine, for example IC511) or forceventilated

(air circulated by means external to and not a part of the machine, for example IC516). - Totally Enclosed Water-Cooled: The machine is a totally enclosed machine cooled by circulating water, the water or water conductors coming in direct contact with the machine parts (IP54, IC70W).

- Totally Enclosed Water-Air-Cooled (TEWAC): The machine is a totally enclosed machine (IP54) cooled by circulating air which, in turn, is cooled by circulating water. It is provided with a water-cooled heat exchanger for cooling internal air and a fan or fans, integral with the machine shaft (e.g. IC81W, IC91W) or separate (e.g. IC85W, IC95W), for circulating internal air. This type of enclosure is sometimes called closed-air cooling water (CACW).

- Totally Enclosed Air-to-Air-Cooled (TEAAC): The machine is a totally enclosed machine (IP54) cooled by circulating internal air through a heat exchanger which, in turn, is cooled by circulating external air. It is provided with an air-toair heat exchanger for cooling internal air, a fan or fans for circulating internal air, and a fan or fans external to the enclosure for circulating external air. Fans can be integral with the rotor shaft or separate (e.g. IC511, IC611, IC516, IC616, IC917, IC957 ). This type of enclosure is also called totally enclosed, tube-cooled (TETC).

- Totally Enclosed Fan-Cooled Guarded: The machine is a totally enclosed fan cooled machine in which all openings giving direct access to the fan are limited in size by the design of the structural parts, screens, grills or expanded metal to prevent accidental contact with the fan (IC411, IP55).

- Totally Enclosed Air-Over (TEAO): The machine is a totally enclosed machine intended for exterior cooling by a ventilating means external to the machine (IC417, IP54). TEAO motors are sometimes used for fan and blower applications where the air being moved passes directly over the motor frame to cool the motor.

Motor Encapsulated or Sealed Windings

Both open and totally enclosed machines can be built with encapsulated or sealed windings.

- Machine with Moisture Resistant Windings: A machine with moisture resistant windings is treated such that exposure to a moist atmosphere will not readily cause malfunction (see IEC 60034-1, IEC 60034-5).

- Machine with Sealed Windings: The machine has an insulation system which, through the use of materials, processes, or a combination of materials and processes, results in windings and connections that are sealed against contaminants (see IEC 60034-1, IEC 60034-5).

Squirrel-Cage Induction Motors

Frame Motors

Squirrel-cage induction motors, 160 kW and below shall conform as follows:

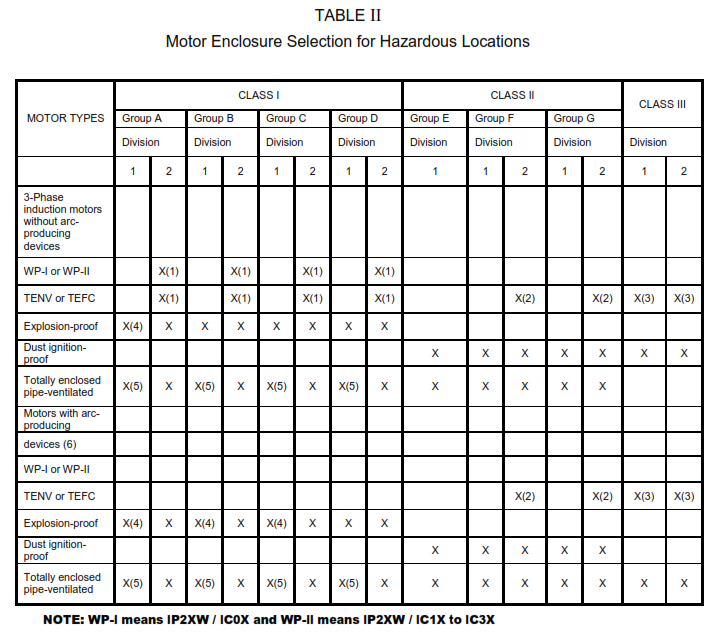

- TEFC Enclosures: Most motors in accordance with IEC60034 have totally enclosed fan-cooled (TEFC) enclosures, which are suitable for most applications, including most Class I, Division 2 applications (comparable with IEC Zone 2 applications). See Table II.

- Explosion-Proof enclosures shall be required for Class I, Division 1 locations (comparable with IEC Zone 0 and Zone 1 applications). See Table II.

Small Motors (56 Frame)

Explosion-proof enclosures are required for single-phase motors in Class I, Division 2 locations and for all motors in Class I, Division 1 locations. Single-phase motors are not recommended for process applications. See Table II.

Large Motors (Above Frame Definition)

Large squirrel-cage induction motors (above frame definition, form wound), 200 kW and larger.

- Weather protected machines: These shall conform to IEC 60034-5 (IP2XW), IEC 60034-6 (IC0X to IC3X). Motors with IP2XW / IC0X enclosures are recommended primarily for clean, dry environments, while motors with IP2XW / IC1X to IC3X enclosures are suitable for normal outdoor ambient conditions, including driving rainstorms. IP2XW, IC0X to IC3X enclosures are also suitable for most Class I, Division 2 applications. See Tables I and II. Weather-protected motors use external air for cooling, thus exposing windings and interior surfaces to high humidity and corrosive gases and vapors. Nevertheless, weather-protected motors are adapted to extremely adverse weather and corrosive conditions by using vacuum pressure impregnated (VPI) insulation on motor windings. VPI insulation systems are impervious to moisture penetration and provide excellent heat transfer capabilities.

- TEFC Enclosures: Because of their high cost, large motors with totally enclosed fan-cooled (TEFC) enclosures are specified only for extremely dirty or corrosive locations. Large motors with TEFC enclosures are suitable for most Class I, Division 2 applications. See Tables I and II.

- TEAAC and TEWAC Enclosures: Large motors can also be supplied with totally enclosed air-to-air-cooled (TEAAC) enclosures, sometimes called totally enclosed, tube-cooled (TETC), and totally enclosed water-air-cooled (TEWAC) enclosures, sometimes called closed-air cooling water (CACW). Manufacturers sometimes provide TEAAC (TETC) enclosures in place of TEFC enclosures in larger motor sizes.

- Explosion-Proof Enclosures: These shall be required for Class I, Division 1 locations. See Table II.

Motors for Class I Hazardous Locations

The following applies to 3-phase squirrel-cage induction motors for use in Class I, Division 1 and Class I, Division 2 locations. For other types of motors for Class I locations and for all types of motors for Class II and Class III locations see Table II.

- Motors Operating on Sine Wave Power: Class I, Division 1. For Class I, Division 1 locations, listed explosion-proof motors are required. Class I, Division 2. For Class I, Division 2 locations, motors with sliding contacts, centrifugal or other types of switching mechanisms, or integral resistance devices shall be approved for Class I, Division 1 locations, unless such devices have enclosures approved for Class I, Division 2 locations. For squirrel-cage induction motors without brushes, switching mechanisms, or similar arc producing devices (that is, non-sparking), standard TENV, TEFC, IP2XW / IC0X, and IP2XW / IC1X to IC3X enclosures are permitted in Class I, Division 2 locations. Motor space heater temperatures shall not exceed 80 percent of the auto-ignition temperature (AIT) of the flammable gas or vapor, and temperatures of internal and external surfaces that may be exposed to the flammable atmosphere shall be considered. Tests have shown that the rotor surface temperature may be well above the stator temperature. The following are recommended. a. AIT Greater Than or Equal to 335 °C. For flammable gas AIT greater than or equal to 335 °C, use a standard non-sparking motor. No special markings are required.

b. AIT Between 225 and 335 °C. For flammable gas AIT between 225 and 335 °C, use a standard non-sparking motor, and provide a nameplate specifying maximum temperature less than or equal to 200 °C.

c. AIT Less Than or Equal to 225 °C. For flammable gas AIT less than or equal to 225 °C, use a standard non-sparking motor, oversized, if necessary to obtain maximum temperature less than 90 percent of AIT, and provide a nameplate specifying maximum temperature. - Motors Operating on Adjustable Frequency Drives. Motors operate hotter on adjustable frequency drives (AFDs) than on sine wave power, so additional precautions are required. AFDs include variable voltage input (VVI) drives, current source inverter (CSI) drives, and pulse width modulated (PWM) drives with and without insulated gate bipolar transistor (IGBT) technology. PWM drives have dominated the low voltage AFD market in recent years.

- Class I, Division 1. A motor to be operated on an AFD in a Class I, Division 1 area shall be a listed explosion-proof motor, and it shall be tested with the specific type of AFD with which it will be used. In

addition, it shall be marked for use with the specific AFD, and it shall be marked with the frequency range and load type (constant or variable torque). - Class I, Division 2. A motor to be operated on an AFD in a Class I, Division 2 area shall be explosion-proof motor.

- Internal Surface Temperatures. Conventional open and totally enclosed induction motors used in Class I, Division 2 locations with Class F insulation shall conform to Figure 1. Maximum rotor surface temperature is expected to be 300 °C under all operating conditions except failure.

(1) WP-I, WP-II, TENV or TEFC induction motors without arc-producing devices may be used in Class I, Division 2 locations. Motor space heater temperatures shall not exceed 80 percent of the AIT of the flammable gas or vapor, and temperatures of internal and external surfaces that may be exposed to the flammable atmosphere shall be considered.

(2) TENV or TEFC motors may be used in Class II, Division 2 locations. Maximum full load external temperatures shall be in accordance with IEC.

(3) TENV or TEFC motors may be used in Class III, Division 1 and 2 locations.

(4) Explosion-proof motors may not be available for all Class I, Division 1 applications.

(5) Where explosion-proof motors are not available for specific Class I, Division 1 applications, totally enclosed pipe-ventilated motors can be used, either force ventilated with clean air or self-ventilated with inert gas.

(6) Motors with arc-producing devices (for example brushes, switching mechanisms) include 3-phase synchronous motors, 3-phase wound rotor induction motors, direct current motors, and single-phase motors with starting switches.