Aircraft components are the various parts and systems that make up an aircraft, enabling it to fly and perform its intended functions. These components can vary depending on the type of aircraft, its purpose, and its design. Here are some of the key aircraft components.

Aircraft Components

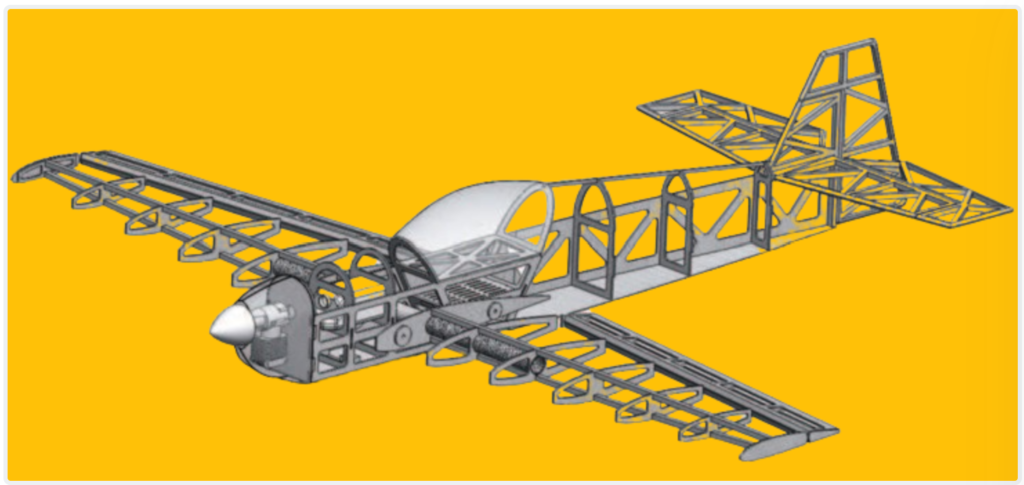

Aircraft are typically constructed from several basic components, each serving a specific purpose in enabling flight and ensuring structural integrity. These components include wings, fuselages, tail units and control surfaces, landing gear, and power plants.

The structure of an airplane encompasses all elements responsible for transmitting and resisting applied loads, shaping the aerodynamic profile, and providing protection to passengers, cargo, and systems against environmental conditions encountered during flight.

In many aircraft designs, the structure comprises thin shell structures, characterized by an outer skin supported by longitudinal stiffening elements and transverse frames. This arrangement allows the structure to withstand bending, compressive, and torsional loads without buckling. Such structures are commonly referred to as semi-monocoque. Alternatively, some aircraft feature thin shells that rely solely on their skins to resist loads, known as monocoque structures.

1. Fuselage – Structural Elements and functions

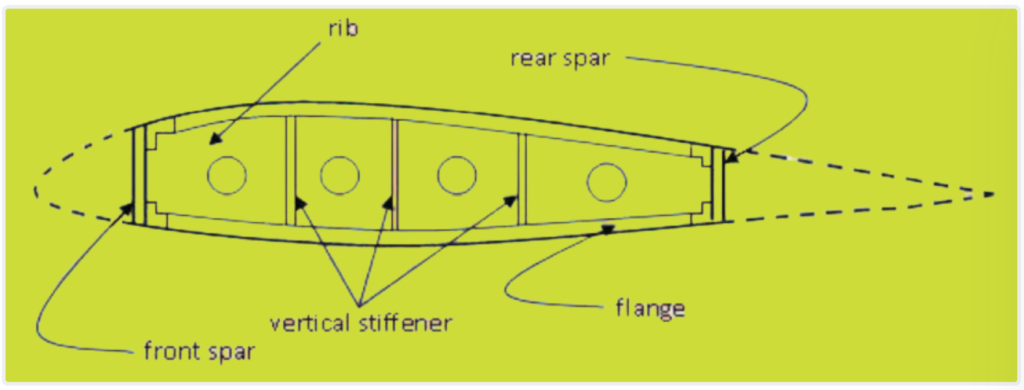

The fuselage serves as the main body of the aircraft, responsible for carrying the payload and providing structural support by connecting all other components. It must withstand various loads, including bending moments from weight and lift, torsional loads from the fin and rudder, and cabin pressurization.

In transport aircraft, the fuselage is typically cylindrical or near-cylindrical, with tapered nose and tail sections. Modern aircraft often employ a semi-monocoque construction, consisting of a stressed skin with added stringers to prevent buckling, attached to hoop-shaped frames.

Frames and bulkheads perpendicular to the skin support and maintain the shape of the fuselage. Frames are open or ring-shaped supports, while bulkheads are closed. Cutouts, such as doors and windows, disrupt the perfect cylindrical shell and require reinforcement to maintain structural integrity.

In pressurized fuselages, both above and below the floor are pressurized, resulting in no pressurization loads on the floor. However, sudden depressurization can lead to loads on the floor until pressure equalizes through side wall vents. Double-bubble fuselages, with varying radii, may experience tension or compression on the floor supports due to pressurization.

Frames provide the cross-sectional shape of the fuselage and prevent buckling under bending loads. Stringers enhance the stiffness of the skin under torsion and bending loads with minimal weight increase. Pressure bulkheads, located at both ends of the fuselage, bear the loads imposed by pressurization. Fatigue-critical areas include the upper fuselage and joints of fuselage frames to wing spars.

2. Wing – Structural Elements and Functions

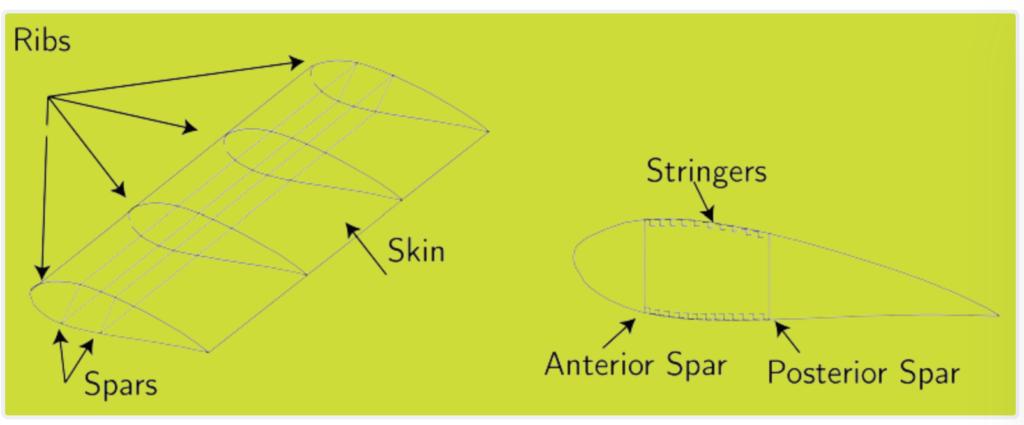

The wing of an aircraft primarily serves to generate lift. It consists of two main parts: the internal wing structure and the external wing skin.

Ribs give the wing its aerodynamic shape and provide support for the skin, preventing it from buckling. They also help to segregate fuel within the wing and serve as attachment points for various components like control surfaces, flaps, landing gear, and engines.

Stringers, or stiffeners, are thin strips of material running spanwise and attached between the ribs. They stiffen the skin, preventing it from buckling under compression loads caused by wing bending, twisting, and aerodynamic forces.

Spars are simple beams that support the ribs and stringers. They are heavily loaded and carry more force at the root than at the tip of the wing. Spars resist bending and shear forces induced by aerodynamic loads, and they help prevent wing twisting.

To resist twisting, some wings incorporate a second spar, creating a torsion-box structure. This arrangement helps distribute torsional loads between the spars and the strengthened section of skin, which serves as both a spar-cap to resist bending and part of the torsion box to resist torsion. Modern commercial aircraft often use two-spar wings to achieve this design.

3. Tail

The structural components of the tail stabilizers are similar to those of the wing. They include ribs, stringers, and spars, which provide support for the tail surfaces and help maintain their aerodynamic shape. These components are exposed to similar aerodynamic forces as those experienced by the wing, but they operate in the rear section of the aircraft, providing stability and control.

4. Landing Gear

The landing gear, also known as the undercarriage, serves multiple functions essential for ground operations of an aircraft. Its primary roles include supporting the aircraft on the ground, facilitating smooth taxiing, and absorbing the shocks of taxiing and landings. Although it remains inactive during flight, it must be designed to be compact, lightweight, and easily retractable to minimize drag and maximize aerodynamic efficiency.

One critical aspect of landing gear design is its ability to withstand the substantial bending moments experienced by the fuselage during ground operations. These moments result from the weight distribution of the aircraft, with the front section housing the cabin and equipment and the rear section accommodating the empennage. To effectively resist these bending forces, a robust beam structure is incorporated into the landing gear arrangement, albeit at the cost of available space for retraction.

During the landing phase, significant forces are imparted onto the landing gear as the aircraft makes contact with the ground. It is imperative to dissipate this impact energy efficiently to prevent structural damage. Therefore, the landing gear is equipped with shock-absorbing mechanisms designed to absorb and dissipate the energy, often converting it into heat. Without proper energy dissipation, the aircraft may rebound upon touchdown, compromising safety.

Following touchdown, the aircraft requires braking to decelerate and come to a stop. Typically, disc brakes are employed for this purpose, providing effective braking performance. Additionally, supplementary braking systems such as air brakes can be utilized to increase drag and aid in slowing down the aircraft. Some aircraft also feature reverse thrust capability, allowing engines to thrust air forward and assist in braking maneuvers. These braking systems collectively ensure safe and controlled ground operations of the aircraft.