1. PURPOSE

2. SCOPE

3. REFERENCES

4. ORGANIZATIONAL RESPONSIBILITIES

5. MATERIALS & EQUIPMENT

6. DOOR INSTALLATION PROCEDURE

7. QUALITY CONTROL & INSPECTION PLAN

8. SITE HEALTH & SAFETY

9. CONFLICTS AND DEVIATIONS

10. DOCUMENTATION

11. JOB SAFETY ANALYSIS.

1. Purpose

To provide documented procedure for the activities related to blast door and hollow metal door installation.

2. Scope

This procedure includes installation of blast door on embedded sub frame & hollow metal doors on wall panels for buildings.

3. References

3.1 International Standards

3.1.1 NFPA 80: Standard for fire doors and other opening protective -National Fire Protection Association

3.1.2 IBC: International Building Codes

3.2 Saudi Aramco Standards

3.2.1 SAES-M-100: Saudi Aramco Building Code

3.2.2 SATIP-M-100-07 Doors & Windows Typical Inspection Plan

3.2.3 SAIC-M-1046 Doors Receiving Inspection

3.2.4 SAIC-M-1047 Doors Pre installation Inspection

3.2.5 SAIC-M-1049 Door Installation Inspection

3.3 Manufacturer’s recommendation

4. Organizational Responsibilities:

4.1 Site Manager

The Site Manager ensures that the Site QC Section are provided with the necessary facilities and cooperation from all Supervisor, Foreman and Labor to enable satisfactory inspection and verification of activities performed by the site civil section.

4.2 Site Engineer/ Supervisor

The Site Engineer/Supervisor and/or foremen are solely responsible in the procedure assuring all materials installed permanently and works being implemented are in conformance with specifications and manufacture’s recommendation.

4.3 QC Manager/QC supervisor

He is responsible to ensure the full implementation of the required minimum quality requirements, Procedures and maintain the required documentation as per applicable company inspection and test Plan for the final acceptance and handover of documents.

4.4 QA/QC Inspector

The QC Site Inspector shall ensure that approved quality control procedure is implemented throughout the course of construction. Inspection shall be done on materials or work, which will be incorporated to the permanent structure. He shall coordinate with Contractor’s Representative regarding inspection and testing activities. Documentation of all inspection and tests made shall also be his responsibility.

4.5 Safety Supervisor

The Safety Supervisor shall ensure that all workers are in compliance with the requirements of the safety manual. He is responsible for monitoring the work area for any unsafe conditions and make corrective actions where necessary.

5. Material & Equipment

5.1. All blast/hollow metal doors & its accessories shall be as per approved MAR, IFC & project specifications.

5.2. Door leafs and frames shall be supplied in damaged free condition with required wrapping/protection and proper tagging for identification.

5.3 Storage of all material shall be done as per manufacturer’s requirement in damage free condition & environment.

5.4 All equipment/tools used for door erection e.g. lifting cranes, welding machine, drilling machine, scaffolding etc. shall be as per ARAMCO specification.

6. Door Installation Procedure

6.1 Blast Door Installation

6.1.1 Begin the installation by SELECTING THE DOOR ASSEMBLY and matching the opening as per the schedule.

6.1.2 Lift the door to a vertical position using appropriate rigging and equipment. If required, a temporary lifting lug can be welded onto the door frame as long as it will not damage any part of the door or its operating hardware once it is used or removed. Lifting of blast door will be done by crane and as per Aramco lifting procedure.

6.1.3 The hinge side of the door must be perfectly plumb to within 1/32 (one-thirty seconds) of an inch for the door to swing properly. Note that while setting, it is extremely important to plumb the hinge side of the door.

a) Check to make sure that the frame is properly located on the hinged side of the concrete wall, once the door & frame are plumbed.

b) Check for clearance around the perimeter of the frame and at the threshold of the of the frame’s sill

6.1.4 Once the door is in positioned, provide enough bracing to support the assembly. Start applying temporary tack welds between the frame and embedded sub-frame along the hinged side of the frame. Use filler strips between the frames and subframe if necessary when the vertical surface of the sub-frame varies from plumb.

Use shims or wedges to hold it in place while making minor plumb and square adjustments, then, apply final welding as indicated in approved shop drawing and as per the company approved WPS until the frame has been securely welded to the sub-frame. Check the plumbness as mentioned above in 6.1.3 & satisfying project specification during welding activity.

6.1.5 Remove all factory applied shipping shims and fasteners.

6.1.6 Make sure that all operating mechanisms inside the door can move freely. All tape and factory-applied shipping materials must be removed from the operating mechanism.

6.1.7 Check for ease of operation.

a) Operate latches and door panel to check for misalignment and binding.

b) Carefully push on the panic bar or turn the outside door handle to open the door. If the handle or panic bar does not move easily, do not apply excessive force. Take necessary action ASAP with help of experts.

c) When the togging pins are retracted, push or pull the door open. Use extreme caution while opening the door. Install the temporary stopper in order to protect the door leaf from any damage.

d) Close the door once opened and check the alignment of the door.

e) Correct as needed

6.1.8 Check for appearance.

a) Clean installation area; grind down all rough edges and welds.

b) Apply TOUCH-UP paint as required.

c) Temporary CAUTION signs as per Aramco requirement will be placed on both side of leaf for safe operation & protection.

d) If required, door leafs and frames will be protected by 150 micron polyethylene sheets and appropriate protection boards.

6.2 Hollow Metal Door Installation Procedures

6.2.1 Structural Opening

During concrete / CMU wall construction, structural opening shall be kept as per construction drawings. Approximately 10mm clear shall be provided all around the door frame.

6.2.2 Door Erection

• Safe manual lifting procedure shall be used for erection of hollow metal door.

• Doors shall be erected as per precise vertical & horizontal alignment with allowable tolerance mentioned in NFPA 80 & relevant SAIC.

• Temporary supports shall be provided to hold the doors to restrict movement, during handling and grouting works.

• Care shall be taken during handling of metal doors to avoid any damage.

• After installation completed, verify proper alignment, levels, lines & plumpness.

6.2.3 Grouting

Approved cementations non-shrink grout shall be used for grouting around the door frame. Mixing & placing of grout shall be done as per grout manufacture’s instruction. Moist curing of grout shall be continued 3 days as per the grout manufacture’s instruction. Grout shall be poured with the help of chute at the door head. Grout shall fill the entire gap around the door frame. Ensure proper consolidation.

6.2.4 Anchoring

Doors shall be anchored to the wall by means of vendor provided anchor bolts. Manufacturer shall provide slots in door frames as per standard practice. Each slot shall be covered with steel putty, during final door coating.

6.2.5 Fixing of Hardware & fixtures

• The list of finishing hardware for each door shall be given in construction drawings.

• Hardware & fixtures shall be as per approved vendor shop drawing, in line with the schedule given in construction drawing.

• Ease of operation for each hardware & fixtures will be checked before final acceptance. If any problem encountered it will be rectified as per manufacturer’s guideline or as per expert’s guidance.

6.2.6 Finishing Works

• Finishing works of doors shall be done as per the finishing schedule given in construction drawings.

• Sealant shall be applied around the door frame at the final wall finishing surface, as shown in construction drawings.

• Sealant material shall be approved, prior to use. Color of the sealant shall be compatible with door color.

• Plastering works of CMU walls shall be terminated with plaster stopper. Sealant shall be applied between plaster stopper & door as shown in the drawing.

6.2.7 Protection

• Temporary CAUTION signs as per Aramco requirement will be replaced on both side of leaf for safe operation & protection.

• Gasket shall be installed before the completion.

• If required, door leafs and frames will be protected by 150 micron polyethylene sheets and appropriate protection boards.

7. Quality Control

All materials, workmanship and inspection shall conform to all Saudi Aramco Typical Inspection Plan, Saudi Aramco Inspection Checklist, Construction Specification, Standard Drawings and IFC Drawings.

8. Site Health & Safety

The work shall be executed in accordance with the approved safety plan. Work permit shall be obtained prior to any commencement of the work as required.

10. Documents

• Approved IFC drawings

• Approved Shop Drawings

• Manufacture Recommendation

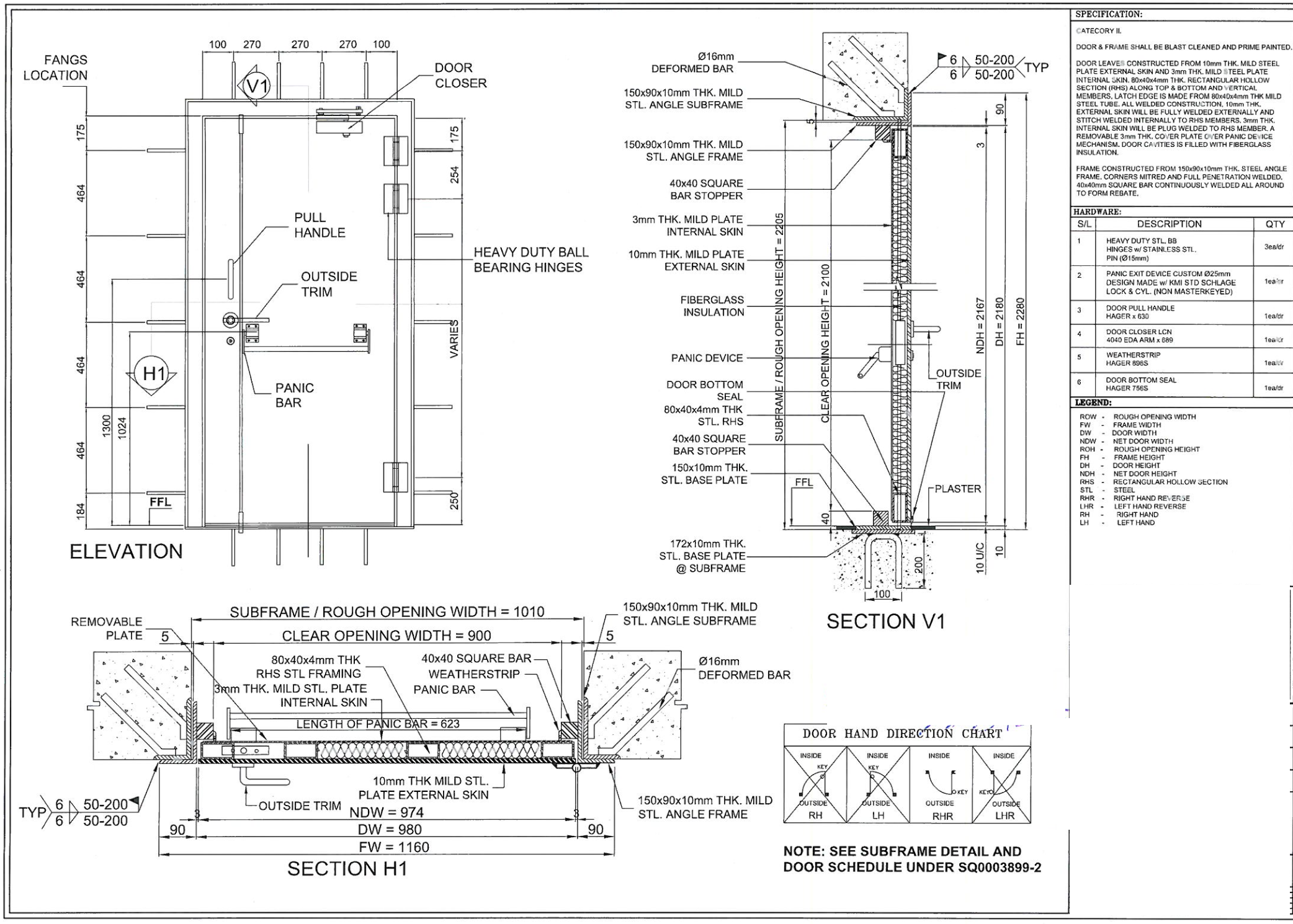

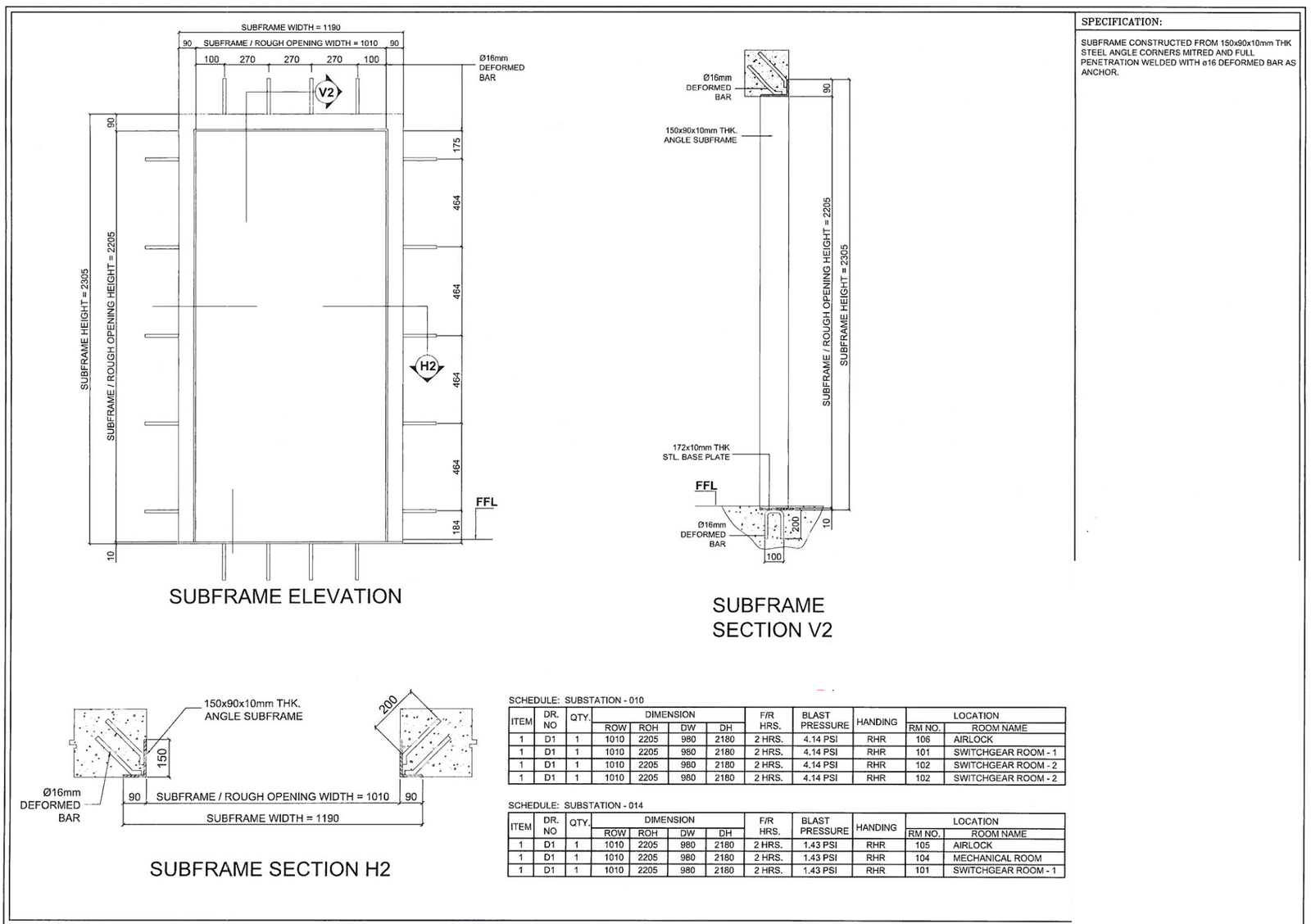

Blast Resistant Door and Frames

Subframe Details and Door Schedules: