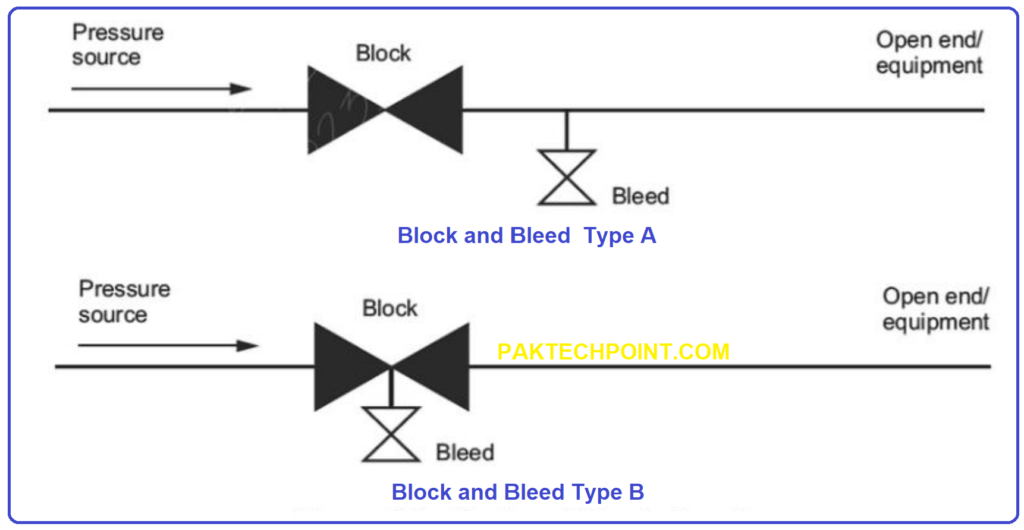

Achieving a BB (Block and Bleed) configuration can be accomplished through various means depending on the valve’s design and application. One common approach is to establish a connection in the pipework or pipeline downstream of the block valve. This configuration allows for isolation of a section of the pipeline while also providing a means to bleed or vent pressure or fluids from that isolated section.

A Block and Bleed Valve (BBV) is a specialized type of valve configuration used in pipeline and process industries to provide additional safety and isolation measures in fluid handling systems. It consists of multiple valve components integrated into a single unit to block the flow of fluid, bleed off any residual pressure, and provide a means of testing or monitoring the integrity of the system. Block and Bleed Valves are primarily used in situations where maintenance, repair, or testing of a downstream segment of a piping system is required, and safety is a critical concern.

Block and Bleed Valve Explanation

Here are the key components and functions of a typical Block and Bleed Valve:

- Block Valve: The block valve is the primary valve in the assembly. It is responsible for isolating or blocking the flow of fluid within the pipeline. When the block valve is closed, it prevents the flow of fluid downstream.

- Bleed Valve (Vent Valve): The bleed valve is a smaller valve located between the block valve and the downstream equipment or pipeline segment. Its purpose is to relieve or “bleed off” any trapped fluid or pressure between the block valve and the downstream section. This is crucial for safety, as it prevents the buildup of pressure that could occur if fluid were to become trapped.

- Vent Connection: The vent connection is typically a small-diameter pipe or tube connected to the bleed valve. It serves as an outlet for the bled-off fluid or pressure. In some cases, the vent connection may also include a plug or cap.

Block and Bleed Valves are commonly used in situations where maintenance or repair work needs to be carried out downstream of the valve. By closing the block valve and opening the bleed valve, the pressure in the downstream section is safely released. This ensures that workers can perform their tasks without the risk of unexpected fluid release or pressure buildup.

Applications of Block and Bleed Valves include:

- Maintenance and repair of equipment such as pumps, compressors, or instruments.

- Isolation of sections of a pipeline for inspection or replacement.

- Safety measures to prevent the unintended release of hazardous substances.

- Monitoring and testing of pressure or fluid integrity in a system.

Block and Bleed Valves come in various designs and configurations, and their selection depends on factors such as the type of fluid, pressure, temperature, and specific safety requirements of the system. These valves are an integral part of process safety management and are designed to minimize risks associated with fluid handling systems in various industries, including oil and gas, petrochemical, chemical, and power generation.

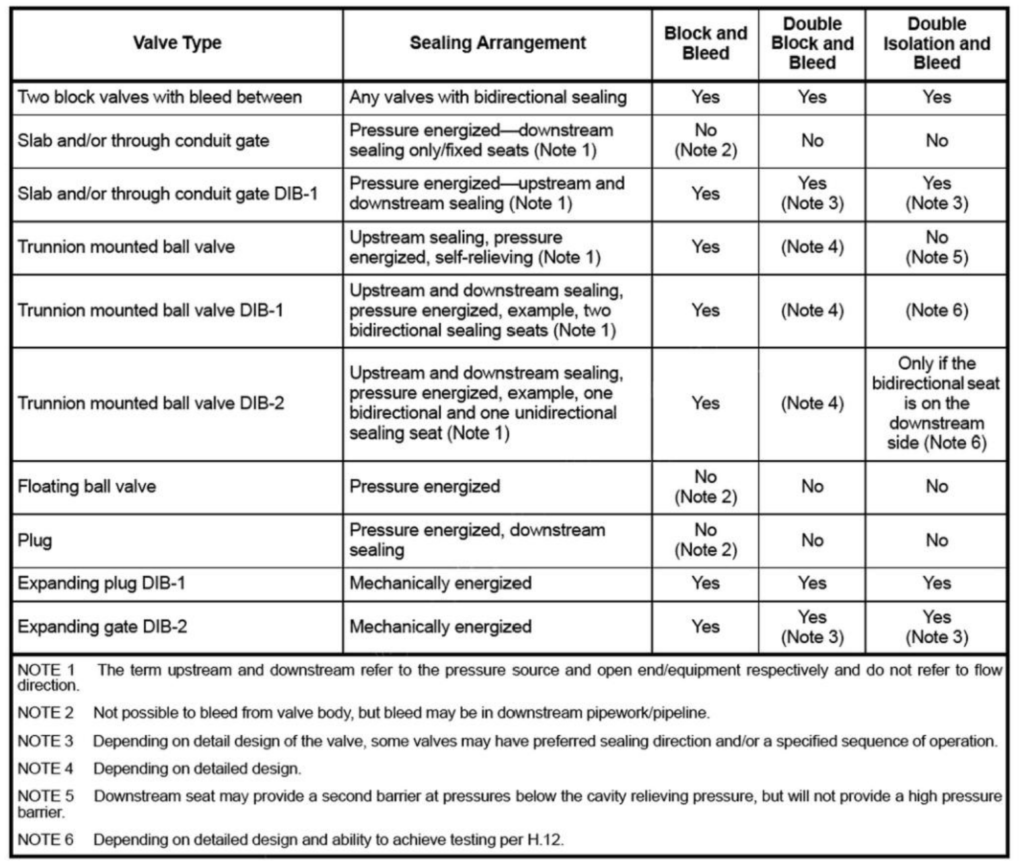

Following Table offers informative guidance regarding typical valve functions and features but is not meant to be exhaustive or limiting. In essence, it serves as a reference point for common valve characteristics, and individual valves may possess unique sealing properties not covered in the table. Therefore, manufacturers should be consulted for specific valve features.

Furthermore, it emphasizes that the user is responsible for ensuring that the operational requirements align with the particular features of a valve, including its sealing capability and function. In other words, it is crucial for users to select valves that meet their specific needs and operational conditions.

The table and accompanying sketches are designed to provide definitions for terms like “block and bleed,” “double block and bleed,” and “double isolation and bleed” as they relate to valve configurations. These configurations involve single or double valve arrangements that offer various levels of isolation and bleed capabilities. However, it’s noted that different documents, including federal regulations, may have distinct definitions for these terms. Therefore, users should be aware of and adhere to the definitions and requirements outlined in the relevant standards and regulations applicable to their specific industry or context.

Read Also: Double Block and Bleed [DBB] Explanation with Diagram and Double Isolation and Bleed (DIB) Explanation with Diagram