The DBB (Double Block and Bleed) feature of a valve or valves pertains to their capacity to isolate and separate two pressure sources while allowing for the controlled bleeding or venting of pressure in the space or void between the two sealing elements, often referred to as “blocks.” The bleeding process may occur either within the pipework or pipeline when two separate valves are utilized, or it can be managed within the valve body itself, positioned between the two seats when the valve is equipped with the DBB feature.

Double Block and Bleed (DBB)

A “Double Block and Bleed” (DBB) valve is a specialized type of valve designed for critical applications where absolute isolation and safety are paramount. It provides two separate seals that block the flow within a pipeline and also includes a means for bleeding or relieving any pressure or fluid trapped between these seals. This design ensures a high level of safety and minimizes the risk of leakage or accidental release of hazardous materials. Here explained DBB Valve as per API Spec 6D.

Key features of a Double Block and Bleed valve include:

- Two Sealing Surfaces: A DBB valve has two separate sealing components or mechanisms that can isolate the downstream and upstream sides of the valve independently. This double-sealing arrangement provides redundancy and minimizes the risk of fluid leakage.

- Bleed or Vent Port: In addition to the two seals, a DBB valve includes a bleed or vent port located between the two seals. This port allows any fluid or pressure trapped between the seals to be safely released or bled off. This is crucial for ensuring the valve is in a safe, depressurized state before maintenance or disassembly.

- Reduced Risk of Cross-Contamination: DBB valves are commonly used in applications where different fluids or gases must be isolated from each other to prevent cross-contamination. By providing two separate seals, these valves ensure that no fluid can pass through when both seals are engaged.

- Safety and Maintenance: The bleed port provides a means for operators to verify that the valve is in the closed and depressurized position before performing maintenance or repairs. This safety feature is especially important in high-pressure or hazardous environments.

![Double Block and Bleed [DBB] Explanation with Diagram](https://paktechpoint.com/wp-content/uploads/2023/08/image-129-1024x600.png)

DBB valves are widely used in industries such as oil and gas, petrochemical, chemical processing, and any application where safety and fluid control are critical. They are available in various designs, including ball valves, gate valves, and needle valves, among others, to suit different requirements and operating conditions.

It’s important to note that the term “Double Block and Bleed” can have variations in its interpretation and application depending on industry standards and specific valve designs. Therefore, users should consult relevant standards and manufacturers’ specifications to ensure they select the appropriate DBB valve for their specific needs.

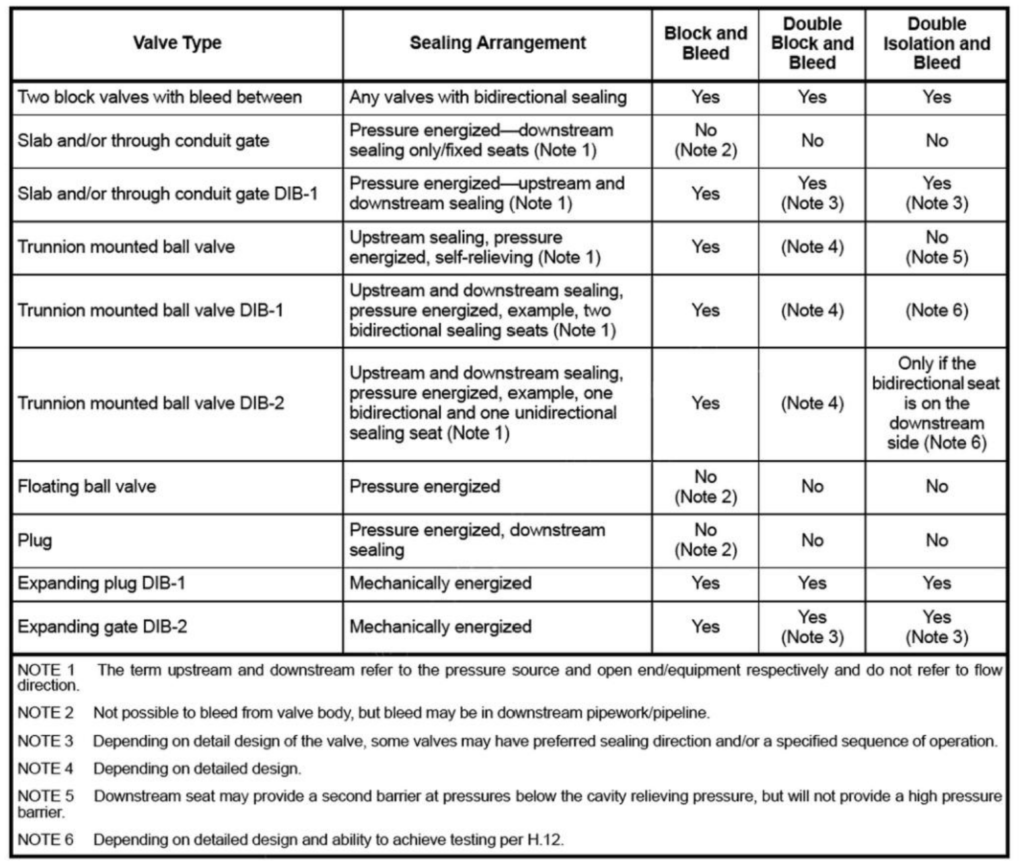

The purpose and limitations of Table following, which is intended to offer informative guidance on typical valve functions and features, particularly related to “block and bleed,” “double block and bleed,” and “double isolation and bleed” configurations. Here’s a breakdown of the key points in this passage:

- Informative Guidance: Table K.1 serves as a reference to provide guidance regarding common valve functions and features. It helps users understand the concepts of block and bleed, double block and bleed, and double isolation and bleed in valve arrangements. However, it’s essential to note that this table is not exhaustive and may not cover all possible valve designs and sealing characteristics.

- Unique Sealing Characteristics: Some valve designs may have unique sealing characteristics that are not fully addressed in Table K.1. These unique features are specific to certain valves and may require consultation with the manufacturer for proper understanding and implementation.

- User Responsibility: The user of the valve is responsible for ensuring that the operational requirements align with the particular features of the valve, including its sealing capabilities and intended functions. This underscores the importance of understanding the specific valve’s capabilities and limitations.

- Definition of Terms: The table and accompanying sketches (Figures K.1 to K.6) aim to define terms such as “block and bleed,” “double block and bleed,” and “double isolation and bleed” within the context of single or double valve arrangements, as specified in the document. These definitions help standardize the understanding of these terms for users of the specification.

- Other Definitions: The passage acknowledges that alternative definitions of these terms may exist in other documents or regulations, such as federal regulations. This highlights the importance of adhering to the specific definitions and requirements outlined in the relevant standards and regulations applicable to a particular industry or application.

In summary, Table K.1 provides valuable guidance on common valve functions and configurations but may not cover every possible valve design. Users are encouraged to work closely with valve manufacturers and adhere to industry-specific standards and regulations to ensure proper valve selection and compliance with operational requirements.