1. Purpose:

The purpose of this Method statement is to provide Building Painting Work Procedure, work sequence and guideline for safe execution of building painting system work to be carried out in the construction of all buildings with cast in place concrete external walls, plastered walls, interior gypsum board walls and exposed ceiling painting for commercial buildings, plants and refinery buildings. All works related to this method statement shall be executed in accordance to project specification, Aramco related standards, IFC drawing, finishing schedule and related international standards including project safety requirement.

Main keyword for this article are Process of Building Painting Work, Painting Work Procedure, Painting Process for Walls (Interior, Exterior).

Building Painting Work Procedure and Method Statement

2. Scope

The application of this method statement shall be limited to Client, its subcontractor construction. This Building painting system will be applied to following building:

3. INTERNATIONAL CODES AND REFERENCE

3.1 Project Specification & Drawing

Building Typical Detail & finishing schedules:

3.2 SAUDI ARAMCO STANDARDS

SAES M 100 Saudi Aramco Building Code

SAEP – 316 Performance Qualification of Coating Personnel

SAES H-001 Selection Requirements for Industrial Coating

SAES H 003 Coating Requirements for Concrete Surfaces

SAES H 100 Painting Requirements for Industrial Facilities

SAES H 101 Approved Protective Coating System

SAES H 101V Approved SA Data Sheets-Paints & Coatings

SAEP-316 Performance Qualification of Coating Personnel

3.3 International Standards

ACI 318M-02 Building Code Requirements for Structural concrete

ACI 311.4R Guide for Concrete Inspection

ASTM D 6237 Standard Guide for Painting Inspectors (Concrete and Masonry)

3.4 Related SATIP & SAIC

SATIP H 003 01 Coating Application on Concrete Surfaces

SAIC-H-1002 Concrete Coatings and Repair Materials Receiving, Storage & Preservation Inspection

SAIC-H-1003 Concrete Coatings Pre-Installation Inspection

SAIC-H-1004 Coating and Final Inspection

SATR-H-1003 Concrete Moisture Field Test (For Coating Purposes)

4. Mobilization of Work Force & Equipment

4.1 Tools & Equipment:

1. Paint Roller

2. Paint Brush

3. Knife

4. Scrapper

5. Grinding Disc

6. Tower Light

7. Portable/Stand Pipe Lights

8. Spray Paint Gun

9. Mixer Machine

10. PPE & other safety requirements

11. Scaffolding

12. Fan

4.2 Human Resources:

1. Site Engineer

2. Foreman

3. Safety Officer

4. Work Permit Receiver

5. Group Leader

6. Skilled Worker(Painter)

7. Flagman for the Equipment

8. Helpers.

5. RESPONSIBILITIES

5.1 Site Manager

The Site Manager ensures that the site QC Section are provided with the necessary information and cooperation from all Supervisors, Foreman, and Labors to enable satisfactory inspection and verification of activities performed by the site civil section and responsible for implementation of HSE on the site.

5.2 Safety Supervisor

The Safety Manager ensures that all safety management will enforced in a ways to prevent injury to personnel, damage to Plants and/or equipment by Fires. He should provide written instruction to established work method, explain the sequence of operation, outline the potential hazards at each stage and indicate precaution to be adopted.

5.3 QC Manager /QC Supervisor

He will be responsible for full implementation of the required minimum quality requirements, procedures and maintain project quality documentation as per applicable company inspection and test for the final acceptance and handover of documents in accordance to the quality plan.

5.4 Civil Supervisor and/or Foreman

The Civil Supervisor and/or Foreman are solely responsible the application of painting or painting works assuring all materials installed permanently and works being implemented are in conformance with specifications and approved drawings.

5.5 QC Civil Inspector

The QC Civil Inspector shall ensure that approved quality control procedure is being implemented throughout the course of the painting job. Inspection shall be done on materials or work, which will be incorporated to the permanent structure. He shall coordinate with client’s representative regarding inspection and test made shall also his responsibility.

6. TEMPORARY WORKS:

6.1 Barricades and sign Boards

Barriers will be erected in coordination with safety department to provide protection against the potential hazard or danger in the work area in all cases where hazard or danger may exist for a period of longer than 8 hours. Barriers will be marked “Red & White” to increase visibility of barrier and highlight the hazard within the area.

6.2 Scaffolding :

Scaffolding will be erected to facilitate areas which require height access. Scaffolding shall be erected by trained and experience scaffolding erectors with the supervision of a competent scaffolding supervisor. Scaffolding materials to be used are those inspected and approved to be use at site.

Erected scaffolding will be inspected and approved by Scaffolding inspector and proper tagging will be used to identify the scaffold of its completeness.

No equipment like (MEWP, Etc.) will be used at SS-10 & SS-14.

6.3 Ventilation System.

To control the humidity pedestal fans will be provided inside the building area, and exhaust fans with hose will be provided for control of dusts, and vapors produce paint.

7.0 QUALITY ASSURANCE

7.1 Painters Qualification

a) Provide at least one person who shall be present at all times during the execution of the work, who shall be thoroughly familiar with the specified requirements and the materials and method needed for their execution, and who shall direct all works performed under this section.

b) Provide adequate numbers of workmen skilled/ certified painter and properly informed of the method and materials to be used.

7.2 Paint Coordination

a) Provide finish coats which are compatible with the prime coats used.

b) Verify the prime coats to be used and ensuring compatibility of the total coating system for the various substrates.

c) Upon request, furnish information on the characteristics of the specific finish materials to ensure the compatible prime coats are used.

7.3 Paint Submittal

a) Product Data: Consisting of manufacturer specification and application instruction for each product, including certification to show compliance with the requirements of this specification.

b) Samples: Submit for approval to the Company Representative.

i. Two Samples of color and gloss for each material upon which the finish is specified to be applied.

ii. Revise and resubmit each sample as required until the gloss, color and texture is achieved.

7.4 Painting Inspection

All painting inspection shall be subjected to available SATIP and SAIC those listed in the above in Section 3 (Reference).

7.5 Product Delivery, Storage & Handling

Delivery: Deliver all materials to the project site in original, unopened containers bearing the manufacturers’ name and label showing the following information:

Name and Title of Material

Manufacturer’s Batch Number

Contents by volume of major constituents

Thinning Instruction

Application Instruction

Date of Manufacture & expiry

Warnings and Special Precaution

7.6 Storage and Handling:

Store all materials inside and under cover in a well-ventilated space and in accordance with manufacturer’s specification. Use all means necessary to protect paint materials before, during and after installation and to protect the work and materials of other trades. In the event of damage, immediately make all repairs and replacements.

8.00 Building Painting Work Procedure

8.1 Surface Preparation Prior to Painting works

8.2 Cast-in-situ, Pre-Cast & Plaster Walls

a) All substrate should be checked and inspected prior to application of the paint.

b) Substrate should be dry, firm and free from dust, sad, loose materials, laitance, dirt grease and oil.

c) New plaster or masonry surface must be allowed to cure and without moisture. Moisture test will be performed to determine the dryness of the surface of plastered masonry wall.

d) Oil and grease contamination should be removed using alkaline cleaner. After removal of the salts, wall should be clean thoroughly with fresh water and let it dry completely. Ensure the moisture content is below 5-10% prior to application of primer.

e) All defects in the surface of the substrata such as cracks, honey comb and angulation or surface imperfection for the cast-in-situ and plastered wall should be repaired with the approved repair materials prior to primer application.

f) Cracks less than 10 mm wide and holes not exceeding 10 mm in diameter shall be filled using a qualified epoxy filler or grout before applying primer/sealer to the surface.

g) Expansion and construction joints shall be cleaned and masked off prior to coating.

h) Surfaces with sharp corners and subject to immersion conditions shall be rounded by forming a fillet with approximately 25 mm radius using an epoxy grout.

i) Sealer/primer shall be use in accordance with the manufacturer’s data sheet and shall be spray applied in a thin coat except for touch-up repairs of small areas [less than 0.1 m²].

j) Paints shall not be used from a container showing a sign of leakage.

k) The painting will be applied after the full curing time of concrete in accordance to SAESQ-001.

l) New concrete must have a moisture content of 4% or less before the painting applications commence.

m) Test report SATR-H-1003 “Concrete Moisture Field Test (For Coating Purposes)” shall be available for review/verification of concrete moisture condition. n) Remove any protrusions and sharp edges with an abrasive power grinding, or power brushing prior to coating concrete.

8.3 Gypsum Board Wall

o) Gypsum wall should vertically align and all fixation screws are properly covered by gypsum putty. All uneven edges of the wall should be level by gypsum putty and sanded prior to any primer application.

p) Before applying the sealer, remove all loose dirt and dust by brushing with a soft brush or by rubbing with a dry cloth. Be sure the joint treatment is thoroughly dry before any application of sealer or paint.

q) Apply one (1) coat of joint compound with broad flexible scraper or spatula to open joints. Follow immediately by applying joint tape over the compound pressing firmly but carefully.

r) Apply second coat of joint compound leveling and overlapping the joint compound. Allow to dry.

s) Sand down and smooth all taped joints and nail/screw heads.

9.00 Painting System, Materials and Application

A. Epoxy Paint for Skirting (Epoxy Paint)

Surface preparation and paint application shall be done according to paint manufacturer’s instruction or recommendation. Normal good painting practice must be followed throughout the entire painting procedure. When the interval is denoted “Extended”, the coated structure can possibly be over coated even after longer periods. This will depend on the actual exposure conditions, such as limited exposure to sun, and on the condition and cleanliness of the paint surface. The evaluation of the specific situation must be based on local experience.

Primer Coat : Apply one (1) coat of STRATA SEALER.

Filler Coat : Apply one (1) coat of STRATA EPOXY MT.

Final Coat : Apply one (1) coat of STRATA EPOXY MT.

| No. | Coating Material Paint | Number of Coats |

| 1 | STRATA SEALER | 1 |

| 2 | STRATA EPOXY MT | 2 |

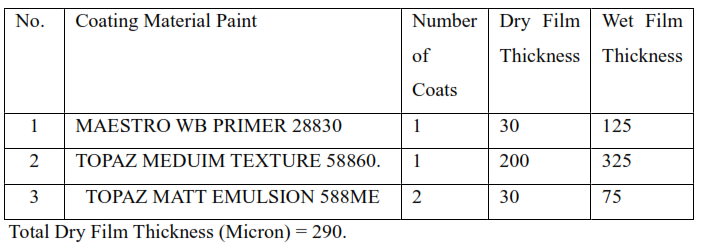

B. Texture Paint for Exterior Walls & Ceiling (Texture Paint)

Surface preparation and paint application shall be done according to paint manufacturer’s instruction or recommendation. Surface to be clean, dry and fully cured. Repair of minor surface imperfections to be done using HEMPEL’S ACRYLIC FILLER 38840 after application of the recommended Primer/sealer.

Primer Coat : Apply one (1) coat of MAESTRO WB PRIMER 28830.

Filler Coat : Apply one (1) coat of TOPAZ MEDUIM TEXTURE 58860.

Intermediate Coat: Apply one (1) coat of TOPAZ MATT EMULSION 588ME.

Final Coat : Apply one (1) coat of TOPAZ MATT EMULSION 588ME.

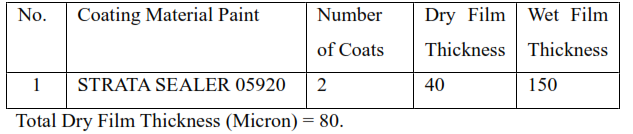

C. Interior for Access Raised Floor System Under (Anti – Dust Paint)

Surface preparation and paint application shall be done according to paint manufacturer’s instruction or recommendation. The concrete must be dry and fully cured. Water capillary activity must be absent. Oil, grease, form oils, or waxes and similar to be removed.

Primer Coat : Apply one (1) coat of STRATA SEALER 05920.

Final Coat : Apply one (1) coat of STRATA SEALER 05920.

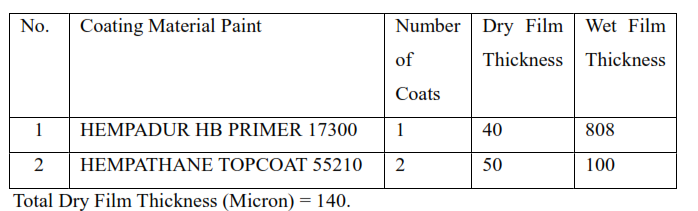

D. Epoxy Primer Paint for Steel Doors (Anti – Corrosion Paint)

Surface preparation and paint application shall be done according to paint manufacturer’s instruction or recommendation. Oil and grease etc. to be removed by emulsion cleaning. Entire area to be (high pressure) fresh water cleaned in order to remove salts and other contaminants. When the surface is dry: Abrasive blasting to minimum Sa 2½ according to ISO 8501-1:2007.

Primer Coat : Apply one (1) coat of HEMPADUR HB PRIMER 17300.

Intermediate Coat : Apply one (1) coat of HEMPATHANE TOPCOAT 55210.

Final Coat : Apply one (1) coat of HEMPATHANE TOPCOAT 55210

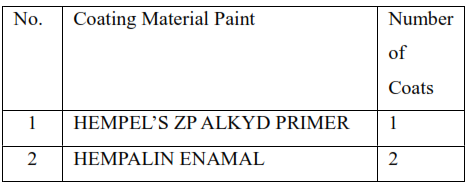

E. Oil Paint for Steel Door (Oil Paint)

Surface preparation and paint application shall be done according to paint manufacturer’s instruction or recommendation. Normal good painting practice must be followed throughout the entire painting procedure.

Primer Coat : Apply one (1) coat of HEMPEL’S ZP ALKYD PRIMER.

Intermediate Coat : Apply one (1) coat of HEMPALIN ENAMAL.

Final Coat : Apply one (1) coat of HEMPALIN ENAMAL

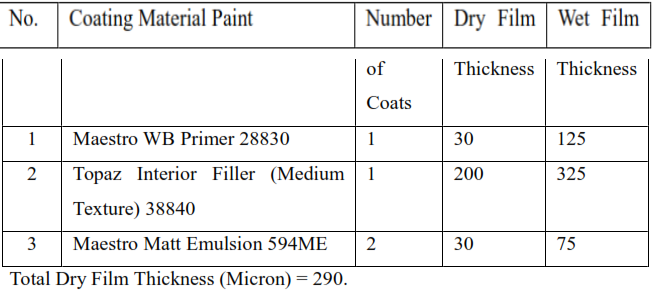

F. Interior Masonry Wall, Exposed Ceiling and Gypsum Board Wall Surface (Emulsion Paint)

Surface preparation and paint application shall be done according to paint manufacturer’s instruction or recommendation. Normal good painting practice must be followed throughout the entire painting procedure.

Primer Coat : Apply one (1) coat of MAESTRO WB PRIMER 28830.

Filler Coat : Apply one (1) coats of TOPAZ INTEROIR FILLER 38840.

Intermediate Coat : Apply one (1) coat of MAESTRO MATT EMULSION 594ME.

Final Coat : Apply one (1) coat of MAESTRO MATT EMULSION 594ME.

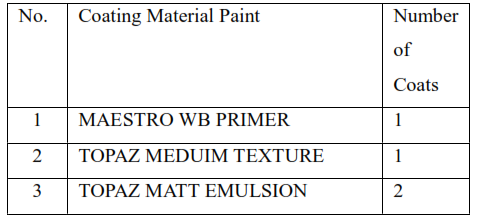

G. External Wall Surface (Emulsion Paint) for Building Painting Work Procedure

Surface preparation and paint application shall be done according to paint manufacturer’s instruction or recommendation. Normal good painting practice must be followed throughout the entire painting procedure.

Primer Coat : Apply one (1) coat of MAESTRO WB PRIMER.

Filler Coat : Apply one (1) coats of TOPAZ MEDUIM TEXTURE.

Intermediate Coat : Apply one (1) coat of TOPAZ MATT EMULSION.

Final Coat : Apply one (1) coat of TOPAZ MATT EMULSION.

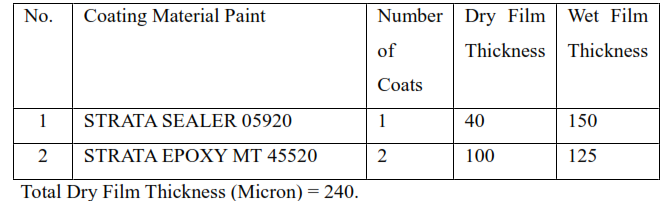

H. Interior Wall and Floor Surfaces (Anti –Dust Epoxy Paint)

Surface preparation and paint application shall be done according to paint manufacturer’s instruction or recommendation. The concrete must be dry and fully cured. Water capillary activity must be absent. Oil grease, form oils, or waxes and similar to be removed.

Primer Coat : Apply one (1) coat of STRATA SEALER 05920.

Intermediate Coat : Apply one (1) coat of STRATA EPOXY MT 45520.

Final Coat : Apply one (1) coat of STRATA EPOXY MT 45520.

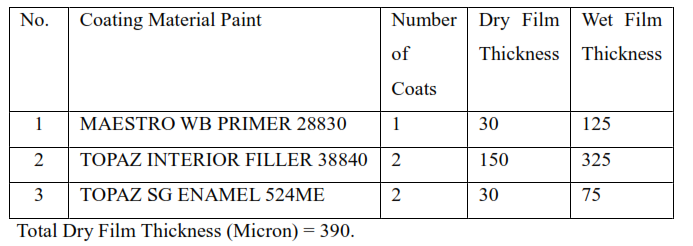

I. Internal Wall Surfaces (Latex Enamel Paint)

Surface preparation and paint application shall be done according to paint manufacturer’s instruction or recommendation. Surface to be clean, dry and fully cured. Repair of minor imperfections to be done using HEMPEL’S INTERIOR FILLER 38840 after application of the recommended primer.

Primer Coat : Apply one (1) coat of MAESTRO WB PRIMER 28830.

Filler Coat : Apply two (2) coat of TOPAZ INTERIOR FILLER 38840.

Intermediate Coat : Apply one (1) coat of TOPAZ SG ENAMEL 524ME.

Final Coat : Apply one (1) coat of TOPAZ SG ENAMEL 524ME.

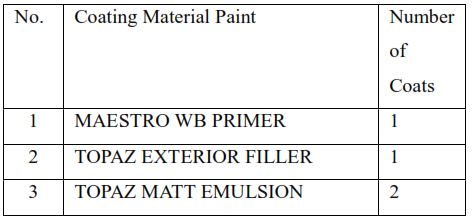

J. Internal Wall Surfaces (Smooth Paint)

Surface preparation and paint application shall be done according to paint manufacturer’s instruction or recommendation. Normal good painting practice must be followed throughout the entire painting procedure.

Primer Coat : Apply one (1) coat of MAESTRO WB PRIMER.

Filler Coat : Apply one (1) coat of TOPAZ EXTERIOR FILLER.

Intermediate Coat : Apply one (1) coat of TOPAZ EXTERIOR FILLER.

Final Coat : Apply two (2) coats of TOPAZ MATT EMULSION.

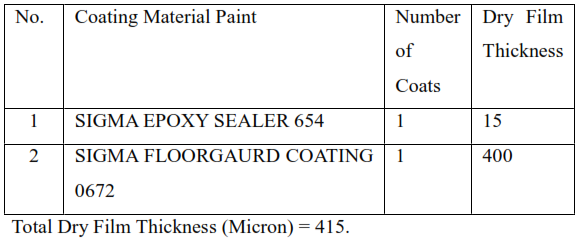

K. Interior Wall Surfaces of Battery Rooms H = 2000mm (Electrolyte Resistant Paint)

Surface preparation and paint application shall be done according to paint manufacturer’s instruction or recommendation.

Primer Coat : Apply one (1) coat of SIGMA EPOXY SEALER 654.

Final Coat : Apply one (1) coat of SIGMA FLOORGAURD COATING 0672.

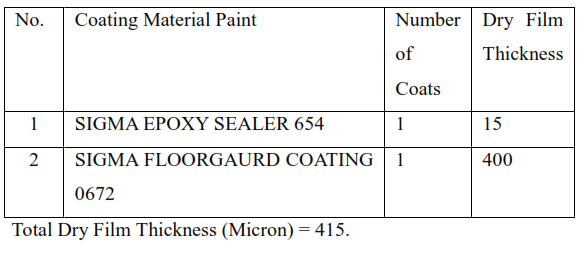

L. Interior Floor Surfaces of Battery Rooms (Electrolyte Resistant Paint)

Surface preparation and paint application shall be done according to paint manufacturer’s instruction or recommendation.

Primer Coat : Apply one (1) coat of SIGMA EPOXY SEALER 654.

Final Coat : Apply one (1) coat of SIGMA FLOORGAURD COATING 0672.

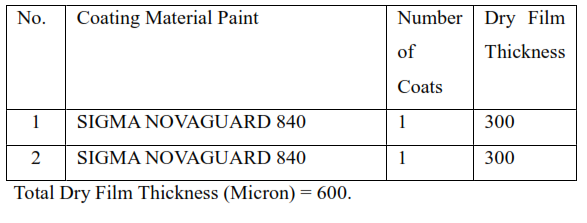

M. Internal Surfaces of Transformers Pits (Epoxy Paint)

Surface preparation and paint application shall be done according to paint manufacturer’s instruction or recommendation.

Primer Coat : Apply one (1) coat of SIGMA NOVAGUARD 840.

Final Coat : Apply one (1) coat of SIGMA NOVAGUARD 840.